By Leslie Langnau • With recent advances in precision, designers can use chains in more applications than ever, including remote installations thanks to lubrication technology.

Chains are versatile and reliable components used primarily to transmit power in machinery or convey products. Roller chains are mainly used with drives. But they can also be found in applications with harsh environments that subject chain to weather, water or chemicals, where other options would fail.

Most drive applications use an ASME/ANSI roller chain wrapped around a driver sprocket that is connected directly to the motor or reducer. This sprocket is usually connected to a machine’s conveyor head-shaft. More after the jump.

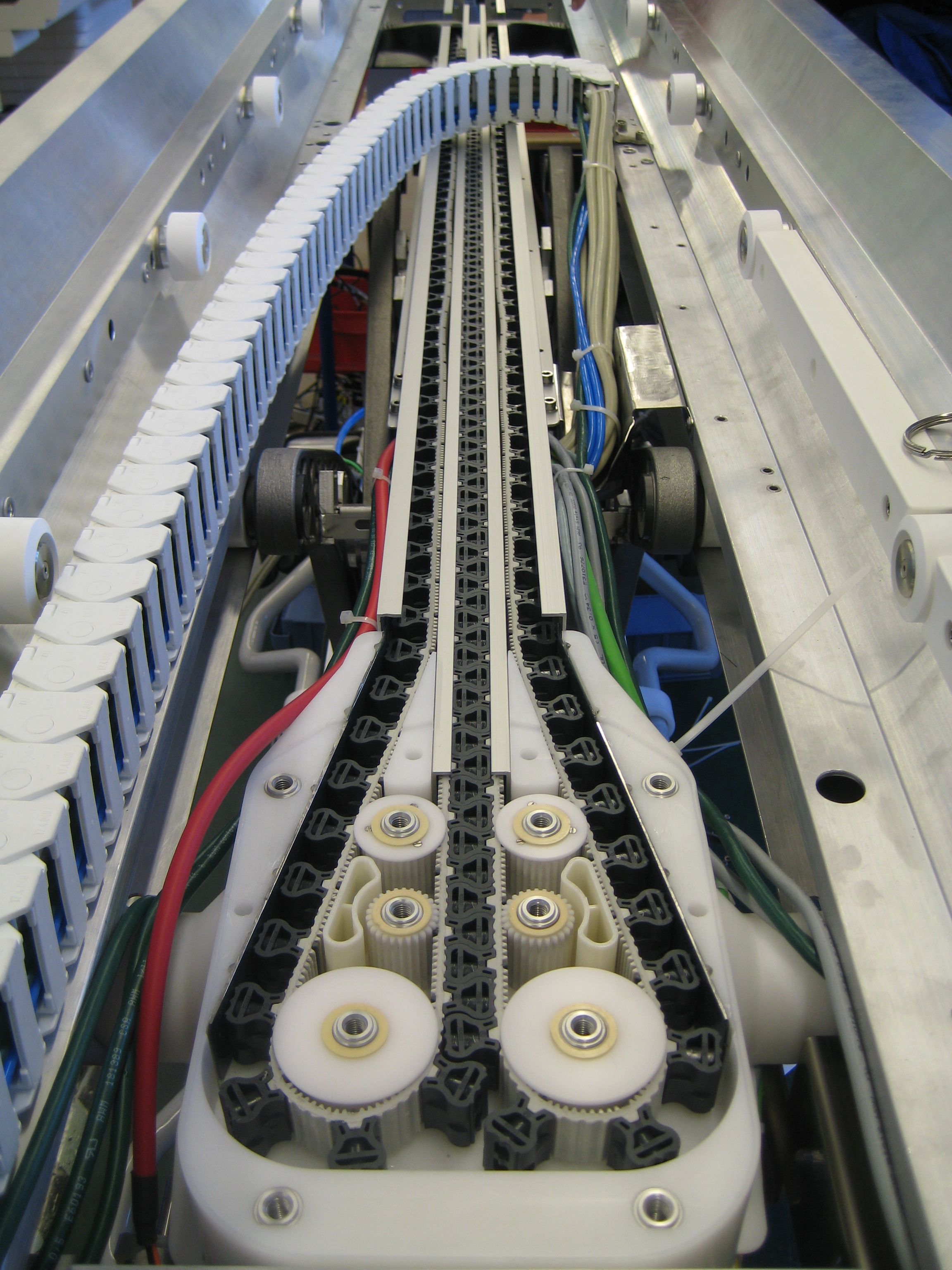

Conveyor chains are used in applications that require moving product horizontally, vertically or around curved radii. Most common conveyor chains are ASME-style (ANSI-style) attachment chains. Types include single-pitch attachment chain, double-pitch attachment chain, hollow-pin chain, curved-attachment chain and plastic-sleeve chain. The attachments accommodate special fixtures or blocks for specific conveyor functions.

Accumulating conveyors are one subtype of conveyor chain that suit applications that need more control over product flow, such as packaging or assembly.

Self-lubricating chains excel in harsh environments

These are useful in applications in food and beverage, paper product or wood-processing industries where traditional lubrication presents too much of a contamination or clogging risk.

Chains are also available with specialty coatings for rugged environments. Stainless steel is a good choice in applications exposed to corrosion, but because this material cannot be hardened in the same manner as carbon steel, it doesn’t have the same load carrying capacity. Nickel-plated chains are another alternative, providing some protection for mildly corrosive environments. More after the jump.

Factors that limit chain life: Corrosion, wear, fatigue

If a chain application requires long life without contamination, pick chain with self-lubricating subcomponents. If the roller chain application requires high precision, pick chain with precision roller bearings at each link connection.

Leave a Reply

You must be logged in to post a comment.