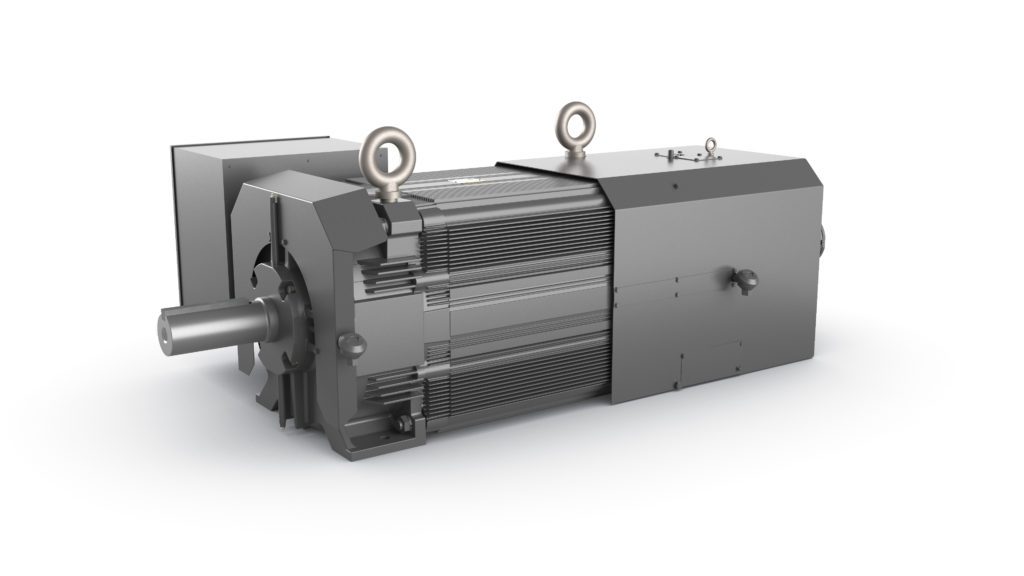

Baldor-Reliance Generation 3 RPM AC motors deliver 1 to 1,750 hp, with customizable speed ranges in nearly any enclosure type. The motors are designed to handle the most demanding applications in industries such as chemical, oil and gas; plastics; HVAC; energy; forest products; metals and industrial automation.

RPM AC motors are optimized for adjustable frequency service — not just a re-rate or over framing of a standard motor. All Baldor-Reliance RPM AC motors are designed to provide continuous constant torque from base speed down to and including zero speed, and — unlike conventional sine wave motors — this means that the RPM AC motor will generate full rated torque, run continuously and not overheat at any speed below base speed. Above base speed, RPM AC produces constant horsepower up to its maximum capabilities.

Gen 3 offers an extended power range, standard grounding provisions, easy setup, and deployment and, when combined with optional ABB Ability smart sensor technology, connectivity and data analytics can be accessed by users and technicians onsite or remotely.

Gen 3 also introduces the web-based RPM AC Wizard, a new tool that allows design engineers to design a motor that best satisfies unique application requirements. Enter horsepower, base speed, top speed and overload requirements, and the Wizard designs a custom motor and full-load current rating that best fulfills the need of the specific application and industry. The wizard also produces complete electrical design curves, performance data and dimension sheets. RPM AC Wizard is a true motor design tool, not just a table look up program.

“RPM AC motors are suitable for use in variable speed applications that have traditionally been the realm of DC motors, but RPM AC offers many advantages over DC, with the most important being reduced maintenance requirements,” says Rick Kirkpatrick, ABB’s Global Product Manager for Laminated AC and DC frame motors. “Generation three keeps the high-performance characteristics that the design engineers have come to trust and adds new features to make the motor easier to specify, install, operate and monitor.”

ABB is a leading global technology company that energizes the transformation of society and industry to reach a more productive, sustainable future. ABB Motion keeps the world turning — while saving energy every day for design engineers, industries, and societies. Digitally enabled drives, motors, and services from ABB Motion deliver top performance, safety, and reliability.

Leave a Reply

You must be logged in to post a comment.