Accurate motion control is crucial in manufacturing medical and clinical devices, such as diagnostic imaging machines and video endoscopes. Even the slightest deviation from specifications can make a device less effective or even hazardous. To ensure the highest quality and safety standards, manufacturers must invest in precise and dependable motion control technology. This guarantees optimal results for patients using their products.

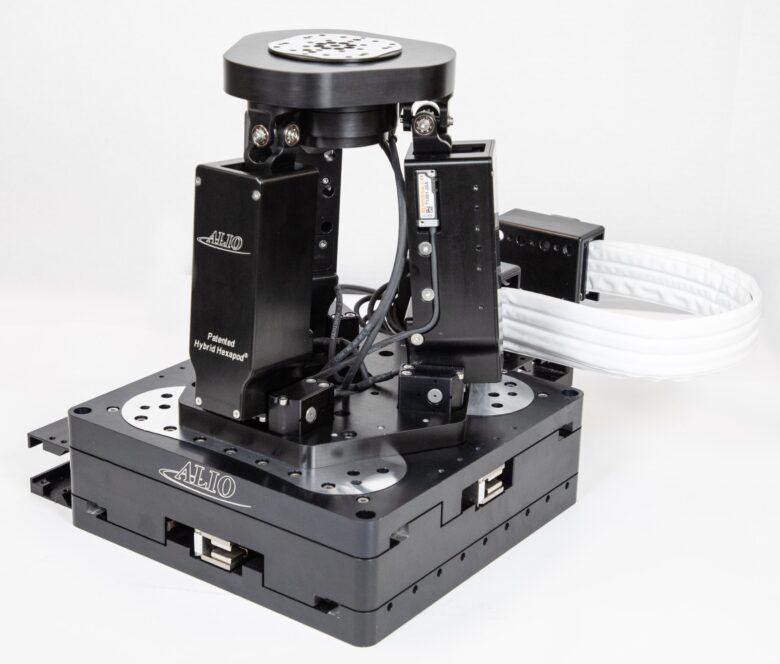

Alio provides the Angulares Hybrid Hexapod for such applications. It accommodates large XY movement to shift the instrument from process step to process step, with six-axis movement at every step without needing to manually move the instrument or use an additional robot to handle components. The Angulares exhibits low friction, low particle generation, is easy to access and clean, and maintains the highest precision. Highly flexible programming enables 4K (and beyond) image quality even using the tiniest and angled endoscopes thanks to the unique ranges of the system.

“The 60° tip/tilt travel of the Angulares Hybrid Hexapod is by far the most angular travel range available from any six-degree-of-freedom (6-DOF) positioner on the market and offers the same unmatched positioning performance found in any of Alio’s full-line of Hybrid Hexapod systems,” said Bill Hennessey, president of Alio. “The Angulares features precision crossed roller bearing guides, optical incremental or absolute encoder feedback on all axes, linear motor or servo ball screw drives, unlimited programmable tool center point locations and coordinate offsets, and zero backlash on all axes. The design makes the Angulares capable of unlimited XY travel, Z travel for 62 mm, which can be increased to 208 mm using other tripod models, tip/tilt travel of 60° (±30°) with continuous 360° Theta-Z, XYZ bidirectional repeatability of less than ± 0.6 arcsec, velocity up to 100 mm/sec XY and Z, and less than 10 nm linear and 0.1 arcsec angular minimum incremental motion.”

The Angulares is part of the Hybrid Hexapod family of motion control systems produced by Alio, the Hybrid Hexapod itself being developed to address the inherent performance limitations of conventional hexapods. Alio’s patented 6-DOF design seamlessly blends and takes advantage of the strengths of serial and parallel kinematic structures while avoiding their weaknesses. The Hybrid Hexapod offers far greater functional versatility, nanometer-level accuracy, repeatability, and superior 6-DOF trajectories than is possible with any traditional hexapod or stacked stage configuration.

“Standard hexapods satisfactorily service applications where micron motion tolerances are required, but as the demand for nanometer requirements expands, standard hexapods struggle. This is because there are performance limitations inherent in all ‘conventional’ hexapod designs. They operate within 3-dimensional space and have errors in all six degrees of freedom. However, hexapod motion systems have typically only been characterized by performance data of a single degree of freedom. This practice leaves error sources unaccounted for in several degrees of freedom, especially in the areas of flatness and straightness, which are critical precision needs at the nanometer-level required in many medical and clinical devices,” said Hennessey.

The unique design of the Hybrid Hexapod is comprised of a parallel kinematic tripod to deliver Z plane and tip/tilt motion. This tripod is integrated with a monolithic serial kinematic stage for XY planar motion. A rotary stage integrated into the top of the tripod (or beneath depending on application needs) provides 360° continuous (Theta-Z) rotation. In this hybrid design, individual axes can be customized to provide XY travel ranges from millimeters to virtually unlimited ranges while maintaining nanometer-levels of precision. Novel forward and inverse controller kinematics provide an unlimited number of programmable tool center point locations plus unmatched path precision and performance.

The 60° tip/tilt travel of the Angulares Hybrid Hexapod provides an ideal motion control system medical and clinical device applications and is perfectly suited for aspheric and freeform optical metrology, silicon photonics packaging and probing, laser micro processing (non-planar substrates and taper control), wafer metrology, camera module alignment and assembly, sensor/image stabilization testing, and optical element and fiber alignment.

Alio Industries

alioindustries.com

Leave a Reply

You must be logged in to post a comment.