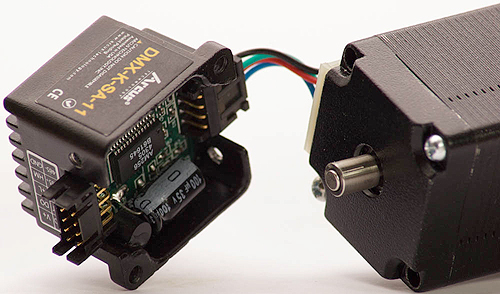

The new DMX-K-SA-11 stepper motor from Arcus Technology (www.arcus-technology.com) integrates Renishaw’s (www.renishaw.com) magnetic encoder chip for real-time position verification. Its compact size enables the motor to stay within the NEMA 11 standard, which is the 1.1-inch-square form factor.

A 16-microstep driver, the DMX-K-SA-11 is capable of 1/16, 1/4, 1/2 or full microsteps in three varying stack sizes. This makes the new stepper motor a great alternative to traditional step motors that operate open loop with sensors to determine position values after the move. Ideal for size sensitive applications requiring open-loop microstep motion, the DMX-K-SA-11 stepper motor is also designed for applications and customers requiring position verification signal from the motor. ARCUS was able to incorporate this capability by integrating the Renishaw AM256 magnetic encoder chip at the back cap, without changing the size or adding encoders or external components.

In addition, its stand-alone control employs Windows-based programming language that is easy to program and similar to BASIC. The new DMX-K-SA-11 motor has a RS-485 communication with a baud rate of between 9600 and 115 K bps. It features a trapezoidal acceleration profile control, driver current from 100 mA to 1.5 A and 12 to 24 VDC voltage input. Aside from opto-isolated digital output, the stepper motor also includes opto-isolated +Limit/-Limit/Home inputs, while its homing routine utilizes limit input or home input.

Leave a Reply

You must be logged in to post a comment.