Sensors and actuators have traditionally been connected to PLCs or other controllers via discrete wires and cable harnesses. But the introduction of actuator-sensor interface, also known as AS-Interface, or AS-I, in the 1990’s offered users and integrators a reliable, cost-effective replacement for the bulky, time-consuming method of parallel wiring.

A new version of actuator-sensor interface, termed ASi-5, was introduced in 2018, offering higher bandwidth and shorter cycle times. However, the most current, widely-available AS-I devices comply with version 3.0, so the focus of this article will be version 3.0.

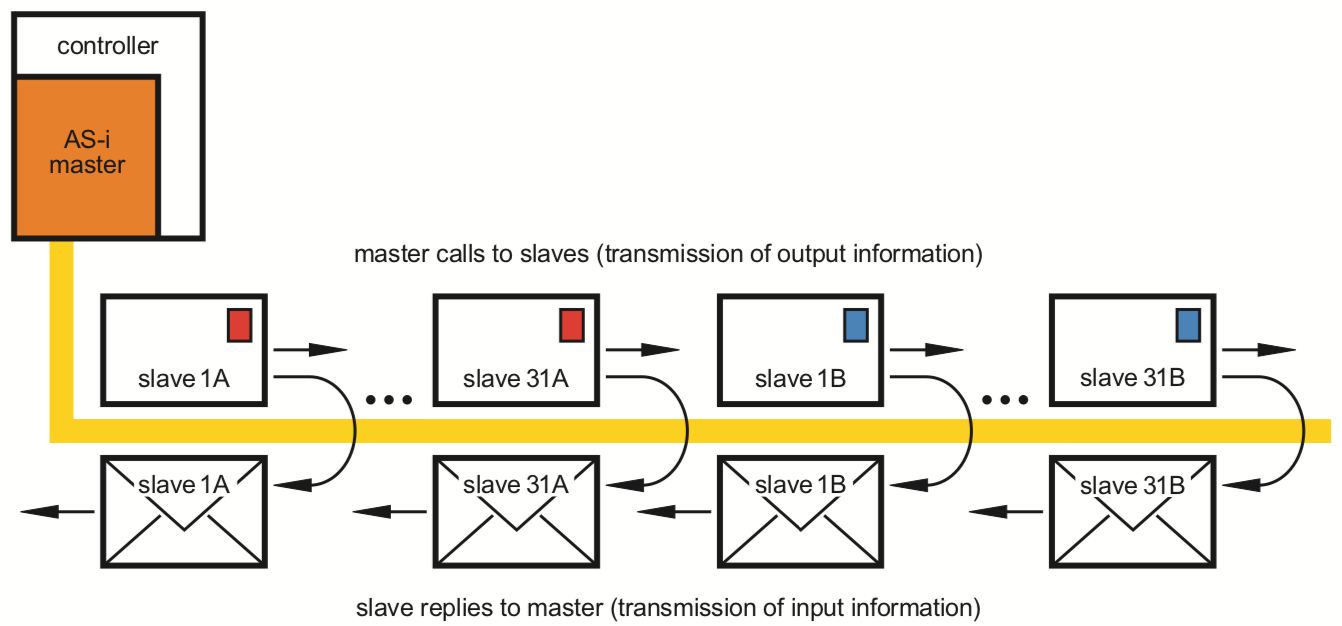

AS-Interface is a master-slave bus, with a single master controlling up to 62 slaves. It operates at the lowest level of the fieldbus hierarchy, but when implemented with an AS-I master/gateway (sometimes referred to as simply an AS-I gateway) it can connect to a higher-level network, such as DeviceNet, EtherNet/IP, PROFIBUS, or others.

Note that AS-I masters are also available for applications that don’t require gateway functionality. The AS-I masters simply connect to the higher-level control, such as a PLC, PC-based control, or DCS (distributed control system).

Image credit: Pepperl+Fuchs

The master/gateway manages communication with the slaves and communicates diagnostic information and faults to the higher-level controller or network. It polls each of the slaves in sequence and waits for a response (referred to as “cyclic polling.”) If a slave fails to respond, the master/gateway repeats the request, and if still no response is received, the master/gateway notes the slave’s address and sends this information to the higher level system.

Image credit: ifm electronic

AS-Interface also offers safety functionality, referred to as “AS-I Safety at Work.” With the addition of a safety monitor, the AS-I network can manage safety devices such as e-stops, light curtains, and door latches, with compliance to safety standards SIL3/PLe.

The main benefits of AS-Interface are its simplicity, low cost, and high speed. Up to 62 AS-I slaves can be controlled by one master when the extended addressing system is used. And each slave can have 8 inputs and 8 outputs, for a total of 496 inputs and 496 outputs. With the standard addressing system and 31 slaves, the maximum response time is 5 ms per I/O point, and with extended addressing, maximum response time is 20 ms per I/O point (with 8 I/O per slave). AS-I also has the benefit of being inherently deterministic and repeatable, so response time is reliable.

Image credit: Bihl-Wiedemann

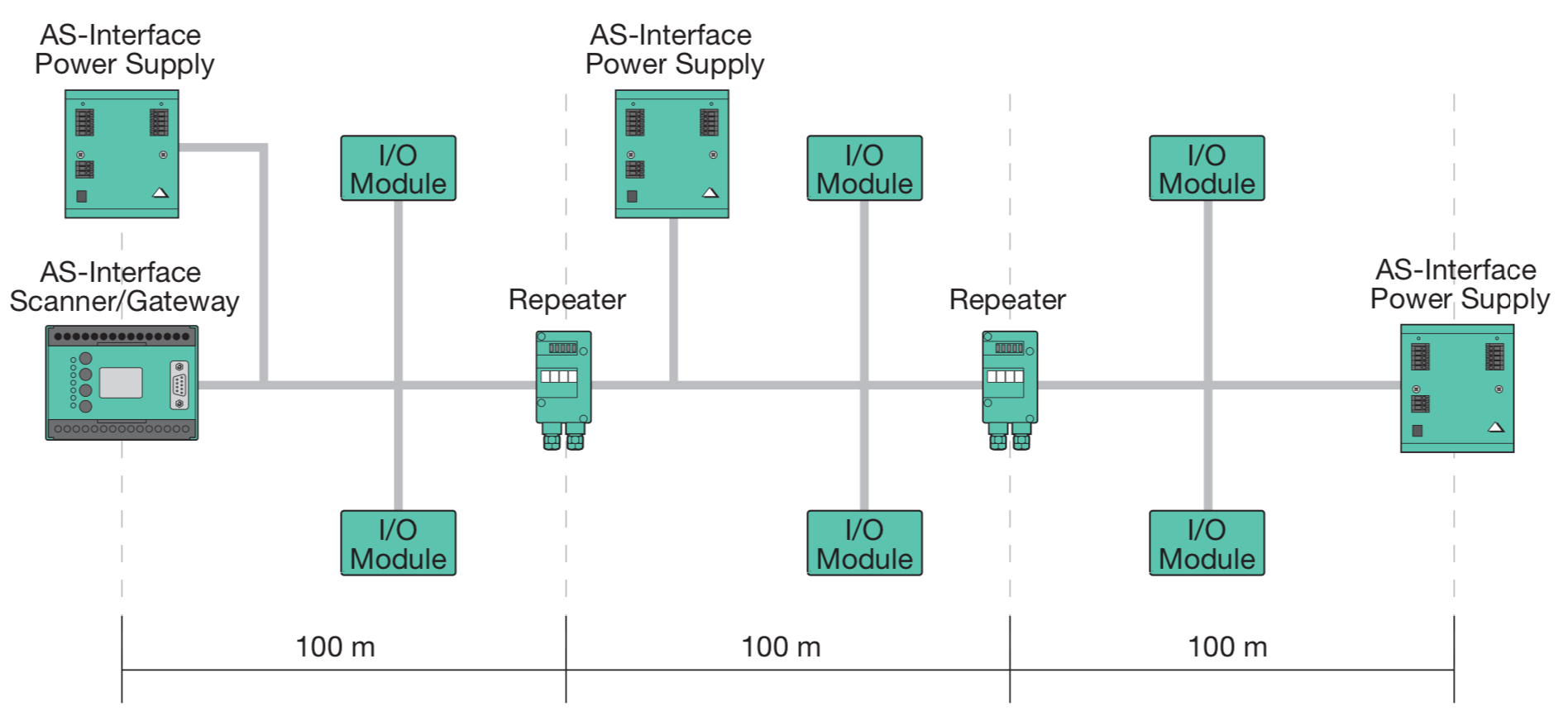

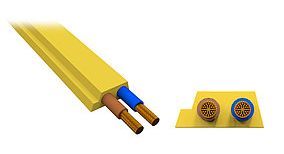

Simplicity comes from the single, unshielded, 2-wire cable that transmits both power and data. Power is provided by a special AS-I power supply that also decouples power from data on the cable. If auxiliary power is required — for devices such as actuators — a separate cable (the same as the main power and data cable, but with a black jacket) can easily be added for a 24 V power supply. The maximum cable length as standard is 100 m, but lengths up to 600 m can be implemented by using repeaters and extension plugs. Connection to both the main cable and the black power cable is via insulation piercing, and slaves can be added anywhere along the cable and in any topology — line, ring, star, or tree. This provides significant flexibility and ease-of-use.

While AS-Interface was originally developed by a group of 11 companies who manufacture sensors, actuators, and control systems, it is a vendor-independent, open standard supported by IEC 62026-2 and the AS-Interface Association.

Leave a Reply

You must be logged in to post a comment.