When electrical equipment is used in a potentially hazardous location — one that contains flammable gases, vapors, liquids, dust, or fibers — it’s important that the potential for fire or explosion be minimized. One way to do this is to use equipment that has been certified as suitable for that environment and not likely to initiate a fire or explosion. In the European Union, equipment to be used in hazardous locations is certified according to ATEX directives, while in other parts of the world, certification is typically done according to the IECEx system.

ATEX

ATEX is the European Regulatory Framework for Manufacture, Installation, and Use of Equipment in Explosive Atmospheres. The ATEX framework consists of two directives.

The ATEX Workplace Directive 1999/92/EC (also referred to as ATEX 137) relates to the health and safety of workers in potentially explosive atmospheres. It applies primarily to employers and addresses selection, installation, inspection, and maintenance of equipment in explosive atmospheres.

The ATEX Equipment Directive 2014/34/EU (also referred to as ATEX 114) replaced the original Directive 94/9/EC in 2016. It applies to manufacturers of equipment and defines essential health and safety requirements and conformity assessment procedures to be applied before products are placed on the EU market.

The ATEX Directives are mandatory by law for both electrical and non-electrical equipment, marketed or sold into the EU, that may be used in potentially hazardous environments.

IECEx

IECEx is the International Electrotechnical Commission for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres. The development of IECEx was primarily driven by the need to facilitate the international trade of equipment to be used in potentially hazardous locations while maintaining the required level of safety.

It’s important to note that IECEx applies only to electrical equipment to be used in hazardous environments (unlike ATEX, which applies to both electrical and non-electrical equipment). IECEx also uses more stringent criteria for evidence during the certification process.

ATEX and IECEx markings

Both the ATEX and IECEx certifications align with the IEC 60079 standards, and in terms of technical requirements, there is little difference between them. Likewise, the marking systems for ATEX and IECEx are very similar, and the two markings are often combined.

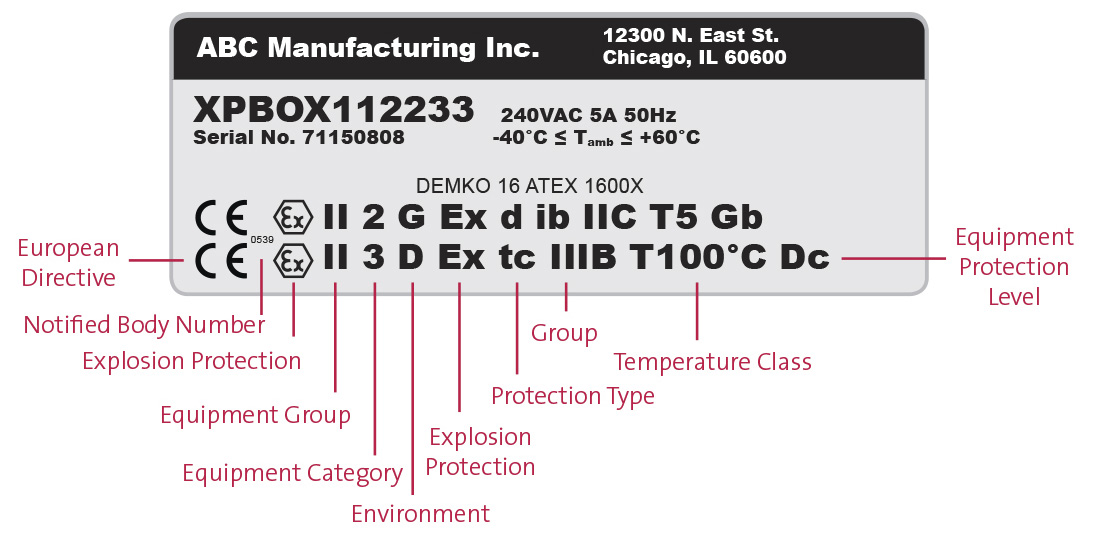

Below, we break down a typical ATEX/IECEx marking for hazardous locations involving gases (top) and dust (bottom) and explain what each component of the marking means.

Image credit: UL

European Directive: The CE mark shows that the equipment has been assessed by the manufacturer and deemed to meet EU safety, health, and environmental protection requirements. This mark includes the Notified Body Number. (The notified body is an organization designated to asses the conformity of products before they are placed on the market in the EU.)

Explosion Protection: The specific ATEX symbol for explosion protection.

Equipment Group: Distinguishes between equipment for use in mines and equipment used in all other areas (sometimes referred to as above-ground industries).

- Group I is for equipment used in mines

- Group II is for equipment used in all other areas

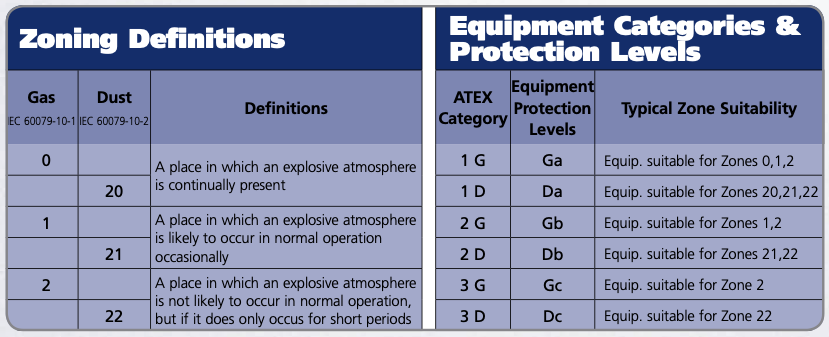

Equipment Category: Directly relates to the hazardous location Zone in which the equipment is intended to be used. A lower Equipment Category number indicates that a higher level of ignition protection is required.

- Categories M1 and M2 are for equipment used in mines

- Category 1 is for equipment intended for use in Zones 0 (gas) or 20 (dust)

- Category 2 is for equipment intended for use in Zones 1 (gas) or 21 (dust)

- Category 3 is for equipment intended for use in Zones 2 (gas) or 22 (dust)

Recall that in the IEC 60079 system of classifying hazardous locations, Zones 0 (gases, vapors, mist) and 20 (dust) are defined as areas where a potentially explosive atmosphere may occur continuously or for long periods of time. Zones 1 and 21 are defined as areas where a potentially explosive atmosphere is likely to exist under normal operating conditions or frequently due to repair, maintenance, or leakage. Zones 2 and 22 are defined as areas where a potentially explosive atmosphere is not likely to occur under normal operating conditions.

Environment: Indicates whether the environment contains hazardous gases, mist, or vapors, or, separately, dust.

- G – gases, vapors, or mist

- D – dust or flyings

The combination of ATEX Equipment Category and Environment correlates to the IECEx Equipment Protection Level (see below).

The first five sections of the marking, from the CE Mark to the Environment classification, are only required for ATEX marking. Taken together, these sections are sometimes referred to as the ATEX prefix.

Explosion Protection: The Explosion Protection indicator used by both ATEX and IECEx.

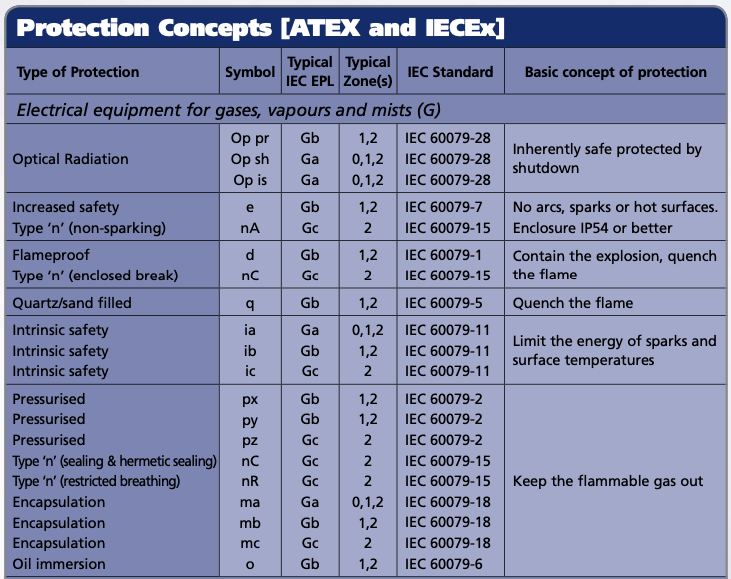

Protection Type: One or two lowercase letters that indicate the method used to prevent ignition in a hazardous environment. Sometimes referred to as the Protection Principle or Protection Concept.

Image credit: Intertek

Group: Equipment is divided into three groups. Sometimes referred to as Gas and Dust Sub-group or Atmosphere Group.

- Group I is for mining (methane gas and coal dust)

- Group II is for gases, vapors, or mist in above-ground industries and includes three sub-groups:

- Group IIA is for gases such as propane

- Group IIB is for gases such as ethylene

- Group IIC is for gases such as hydrogen/acetylene

- Group III is for dust or flyings in above-ground industries and includes three sub-groups:

- Group IIIA is for flyings

- Group IIIB is for non-conductive dust

- Group IIIC is for conductive dust

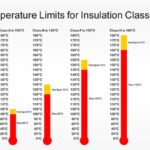

Temperature Classification: Defines the maximum surface temperature that the equipment may reach. For dust explosion proof equipment (bottom example), the maximum surface temperature is stated directly, rather than with a temperature classification code.

Equipment Protection Level (EPL): Only required for IECEx marking. The Equipment Protection Level consists of an uppercase letter G (gas) or D (dust), along with a lowercase letter that indicates the hazardous location Zone in which the equipment is intended to be used.

Image credit: Intertek

Leave a Reply

You must be logged in to post a comment.