Traditional electromagnetic servo and stepper motors experience electrical and mechanical losses, which result in heat generation and can limit their performance. Piezo motors also experience losses and heat generation, but since they operate via the piezoelectric effect and have no mechanical parts, their performance is affected by different factors. Due to their low conductivity and […]

FAQ: What are flexure guided piezo actuators?

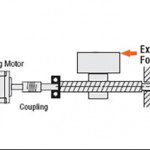

When a voltage is applied to a piezoelectric material, it generates motion and force due to the expansion or contraction of the material. Piezo actuators take advantage of this effect, incorporating piezoelectric materials into useful devices for generating very small, high-frequency movements and producing relatively high forces. Flexure guided piezo actuators incorporate mechanical hinges (flexure […]

FAQ: Where are ultrasonic piezo motors suitable?

Ultrasonic piezo motors harness oscillations induced in a piezoelectric material to produce motion, which can be either rotary or linear. Their design and operation are relatively simple but allows them to achieve very high accelerations and speeds, and to produce high holding forces when no current is applied. Construction and operation For rotary motion, the piezo […]

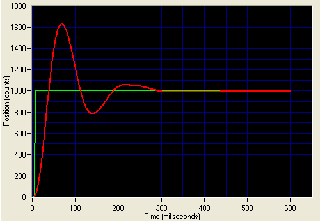

FAQ: How are the controls for servo motors tuned?

Servo motors are used in closed loop systems and operate based on error feedback—the comparison of a target value to the value actually reached by the motor/load. Because mechanical systems have inertia and compliance, the target value is rarely achieved on the first position command—hence, the need for feedback and correction commands. Servo tuning is […]

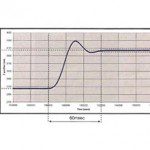

FAQ: What is settling time in a motor-driven servo system?

One of the unique characteristics of servo systems is that they operate in closed-loop mode. This means they use feedback—from a resolver or encoder on the motor, and sometimes from an encoder on the load—to compare the commanded value (typically position, speed, or torque) with the value that was actually reached. Based on this feedback, […]

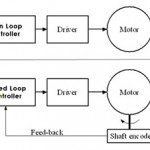

How are servo motors physically different from motors that run open loop?

A servo motor is, by definition, one that runs closed-loop, with feedback to control the motor’s position, speed, or torque. Of motors that run open-loop, with no feedback device, stepper motors are the most common type. Despite their different control mechanisms, stepper and servo motors have a few characteristics in common. First, they both have […]

Best DC motors for high starting torque?

A DC motor can be constructed in various ways, and each design has specific performance characteristics, particularly regarding speed and torque production. The rotor is basically the same in all DC motors, being made of windings that generate an electromagnetic field when current passes through them. But the stator can be made of either permanent magnets […]

Detent torque and holding torque

One feature of stepper motors that differentiates them from other motor types — particularly servo motors — is that they exhibit holding torque. This means that when the windings are energized but the rotor is stationary, the motor can hold the load in place. But a stepper motor can also hold a load in place […]

What is a commutator?

The operating principle of a DC motor is based on the interaction between the magnetic field of a rotating armature and the magnetic field of a fixed stator. As the north pole of the armature is attracted to the south pole of the stator (and vice-versa), a force is produced on the armature, causing it […]

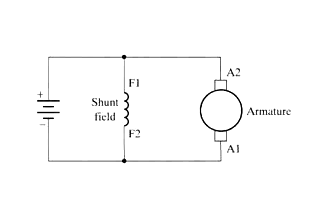

FAQ: What are DC shunt motors and where are they used?

In electrical terminology, a parallel circuit is often referred to as a shunt. Hence, DC motors in which the armature and field windings are connected in parallel are referred to as DC shunt motors. The variations in construction between series-wound DC motors and DC shunt motors result in some differences in operation between the two types, but […]