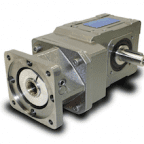

Bodine Electric Co. now sells 24A4-60P planetary PMDC gearmotors. These integral gearmotors combine Bodine’s high-performance type 24A PMDC motor with the all-new 60P (60 mm) planetary gearhead. It is suitable for applications that need higher torque than conventional helical or spur gearheads of a similar size can provide … and where very low backlash gearhead isn’t required. Applications include conveyors, pumps, packaging, industrial automation and wide range of solar- or battery-powered equipment.

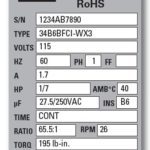

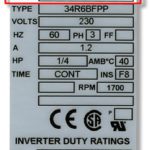

24 standard models include gear ratios from 4:1 to 162:1. The stock models come with 90/130-V, 24-V and 12-V windings. Torque is 4.6 lb-in. (0.5 Nm) to 226 lb-in. (26 Nm). The 24A-60P gearmotor meets IP-66 ingress protection standards (though note that an optional face mount seal kit is needed to seal the output shaft to IP-66). Stock models are come in either imperial or metric drive shaft and mounting sizes.

The new 60P gearhead (designed and manufactured by Bodine) is an unvented unit that mounts in any orientation. The gearhead is permanently lubricated with a high-performance grease and features needle-bearing-supported (and hardened) steel gears for long life and performance. The standard backlash of this gearhead is less than one degree. OEM models are available with accessory shafts and mounting options for encoders and brakes.

The 24A-60P planetary gearmotors and their corresponding flange mount accessory kits are available through Bodine’s extensive distributor network or from the Bodine web site. Custom designs are available to qualified OEMs. Typical OEM modifications include factory installed encoders or brakes, custom windings or wire harnesses, and application-specific mounting and shaft details. For more information, visit the dedicated page to the product specifications at bodine-electric.com.

Bodine Electric Co. offers over 1,200 standard stock products, and thousands of custom designed fractional horsepower (FHP) gearmotors, motors and motion controls (fixed and variable speed AC, brushless DC, and permanent magnet DC). Bodine gearmotors and motors are designed for demanding industrial and commercial applications such as medical devices, scientific and laboratory equipment, labeling equipment, printing presses, packaging equipment, and factory automation. Bodine Electric is headquartered in Northfield, Illinois (20 miles north of Chicago) with manufacturing and assembly operations in Peosta, Iowa, U.S.A. Bodine’s quality management system is certified to ISO 9001.

Leave a Reply

You must be logged in to post a comment.