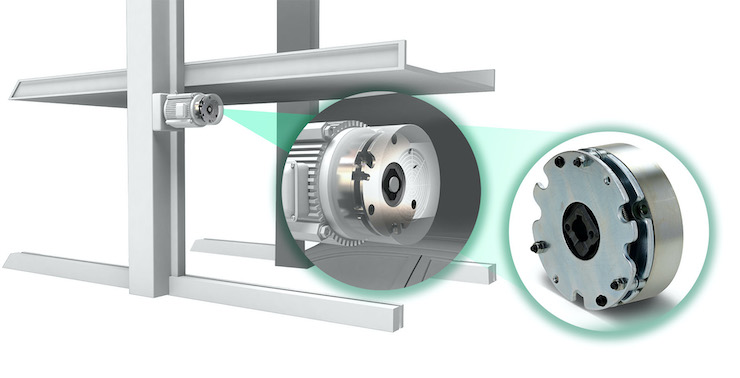

Spring-actuated BXL Brakes from Miki Pulley are designed for the challenging requirements of elevator and lift applications. Designed exclusively for dynamic braking, these brakes are designed for constant elevator usage where long service life with high wear resistance is required.

BXL Brakes feature minimal torque fluctuation, even when stopped from maximum RPM. This ensures a smooth elevator and lift stop without any jarring motion. Also important, these are quiet operating brakes. Excessive braking noise is minimized by the brake’s flat spring design strategically located on the brake’s rotor hub.

Additional features include lightweight, space saving design configuration, long service life, stable and reliable braking power. The brakes are easily installed, and they require no maintenance.

The specification range for the BXL Brakes are:

- Brake torque: 1.475 to 16.226 ft/lb (2 – 22 Nm)

- Brake outer diameter: 3.268 to 76.221 in. (83 to 158 mm)

- Ambient Temperature: 14 ~ 104 °F; (-10 ~ 40 ℃)

Other applications include robotic systems, printing presses, food and paper processing systems, packaging equipment, textile manufacturing systems and many servo & stepper motor driven systems.

For more information, visit www.mikipulley-us.com.

Leave a Reply

You must be logged in to post a comment.