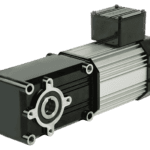

Brother Gearmotors, a division of Brother International Corporation, will showcase its new line of brushless dc electric gearmotors (BLDC) at Process Expo, September 19-22 in Chicago. Brother Gearmotors will be located at Booth #4302.

Also known as electronically commutated motors, Brother’s portfolio of brushless dc gearmotors are suitable for environments requiring virtually maintenance-free operation and accurate speed control as well as operation over a wide speed range. They are also desirable for settings where brush dust contamination is to be avoided or brush contact arcing could affect electronically sensitive equipment.

“Brother brushless gearmotors offer a variety of benefits, including maximized efficiency, safety, system control and power density,” said Matthew Roberson, Vice President of Brother Gearmotors.

Brushless DC gearmotors from Brother Gearmotors are cost-effective, compact and long lasting, and offer several advantages over brushed DC motors, including:

- Virtually maintenance free; lubricated and sealed for life

- Extremely configurable; several shaft configurations and custom options available

- High efficiency, further enhanced with quiet helical and hypoid gearing

- Safe 12-48 VDC motors with a wide speed control range

The new brushless motors are designed to work with an OEM’s own design drive or standard brushless drives from Brother with features such as adjustable acceleration, deceleration, open or closed loop operation, current limiting and other performance and safety features.

For more information, visit www.brother-usa.com/gearmotors.

Leave a Reply

You must be logged in to post a comment.