Kollmorgen introduces AKD™ BASIC servo drives. These Ethernet-based drives feature an integrated single axis motion controller, enabling OEMs to build a more compact and cost-effective machine than is possible with a separate drive and PLC configuration. The camming, s-curve and free-form motion profile capabilities delivered by the integrated motion controller, combined with the simplicity of BASIC programming language and a built-in Program Editor with debugging tools, enables machine builders to easily execute complex processes, faster.

Having machine control built right into the drive enables design engineers to eliminate some small to medium PLCs from the machine. This reduces the amount of wiring, number of components and dedicated panel space, enabling OEMs to reduce the cost and size of their machines. AKD BASIC also works well in machines that still require a PLC with multiple interfaces, including digital I/O and Ethernet communications.

The integrated high-performance motion controller can also help users run more complex processes and increase machine throughput in single axis applications. The fast interrupt routines and conditional “when” statements ensure fast program execution, which is key for coupling motion and machine control. These routines and “when” statements are scanned every 250 microseconds. Users will also be up and running faster because the easy-to-learn BASIC programming language simplifies program flow control to significantly reduce the time needed to complete project code. Additionally, a Source Code lockout feature helps AKD BASIC users protect their machine designs and IP; functionality that further helps machine builders achieve and maintain a competitive advantage.

With AKD BASIC, OEMs can leverage Kollmorgen’s engineering capabilities to achieve customized product variants that deliver differentiated machine performance faster and more cost effectively, and without the risks associated with customized solutions.

A Programming Editor is integrated into the same AKD WorkBench as the rest of the AKD servo drive family; no extra software package is required. The user-friendly program editor provides Syntax Highlight, Auto-Complete, Auto-Format and code snippet functionality for faster code development. The program editor also includes debugging tools that enable single-stepping, break-points, and step over program control.

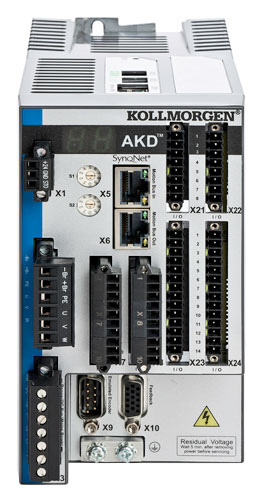

An optional expanded I/O version of AKD BASIC servo drives is available. With this option achieving 20 total digital inputs and 12 total digital outputs, it can eliminate the need for remote I/O to reduce wiring requirements and costs. The optional expanded I/O version also comes with an SD memory card, enabling users to transfer programs without requiring a PC, simplifying maintenance and replication of drives.

KOLLMORGEN

www.kollmorgen.com

Leave a Reply

You must be logged in to post a comment.