If you went to college in the 1990’s or earlier and were interested in engineering, you generally had eight or ten fields of study to choose from:

— Mechanical Engineering

— Aerospace Engineering

— Electrical Engineering

— Computer Science (often included in the Engineering department)

— Civil Engineering

— Industrial Engineering

— Chemical Engineering

— Materials Science Engineering

— Nuclear Engineering

Those of us who landed in the automation industry in the past two decades typically came from either a mechanical engineering or an electrical engineering background. And while both mechanical and electrical engineering programs cover a broad range of topics within their respective fields, there has historically been little overlap between the two.

Case in point: Those of us from the mechanical side were great at calculating forces and inertias but had limited expertise in motor and control theory — much less the practical application of motors and controls to linear or rotational systems. And those of us from the electrical side were great at the hands-on integration of motors and controls, but typically lacked experience in the fundamentals of mechanical design, such as calculating beam deflection or tensile strength. If you found someone who had mastered both fields — mechanical and electrical engineering — they either had many years of experience under their belt, or they had, at some point in their career, been thrown into a “sink or swim” situation and learned out of necessity and self-preservation.

But the silos that were mechanical and electrical engineering programs are changing. There are now engineers coming out of both 2-year technical programs and 4-year degree programs who are educated and ready to hit the ground running with practical experience in mechanics, electrical hardware, electronics, controls, and software. This new, diverse type of graduate is the product of mechatronics engineering: a field of study that first became available in the late 1990s and has seen significant growth over the last decade.

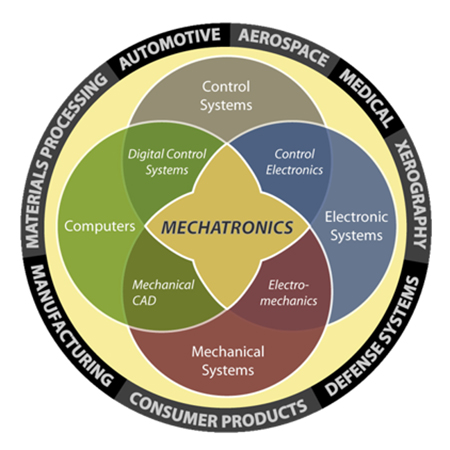

The term “mechatronics” was first coined by an engineer at Yaskawa Electric Corporation, stemming from the combination of mechanics and electronics.

Image credit: K. Craig

Mechatronics engineering programs can now be found at community colleges, technical schools, and universities. These programs range from two-year associate degrees or technical certificates with a focus on practical, hands-on training, to four-year degrees that cover everything from engineering theory to hands-on applications, to humanities and social-science courses that will give modern engineers the “soft” skills they’ll need alongside their technical expertise.

Regardless of the length of the program and the type of certificate or degree awarded, one thing the mechatronics engineering curricula all have in common is that they combine mechanical, electrical, and computer science disciplines with hands-on training in software, controls, sensors, and networking to produce students who can effectively work in advanced manufacturing facilities.

Mechatronics engineering is inherently tied to the manufacturing industry, although it also has application in other fields such as surgical robots, aerospace, and even agriculture. In fact, industry leader Siemens sees the need for mechatronics education as such a critical part of manufacturing’s future that it has developed the Siemens Mechatronic Systems Certification Program (SMSCP). This program, which can be integrated into existing programs at schools and universities, provides training and teaching resources to schools and instructors, along with certification for students to ensure they have the necessary competencies for specific job profiles in mechatronics disciplines.

The rise in popularity and availability of mechatronics engineering programs could be a godsend for the manufacturing industry. A recent study by Deloitte and The Manufacturing Institute found that the US manufacturing labor shortage could equal 2.4 million by 2028. Much of this shortage is attributed to three factors: the retirement of baby boomers, with fewer millennials to take their place; shifting skills requirements, which are increasingly dependent on technical training and technology degrees (although not necessarily four-year degrees); and a misrepresentation of manufacturing jobs, which will require a concerted effort from manufacturers to overcome.

The report from Deloitte debunks the theory that advanced technologies such as automation, AI, and IoT are eliminating jobs. Instead the report finds that more jobs have been created thanks to these technologies. From the report:

For more than two centuries, the manufacturing industry has adopted new technologies and provided new jobs for workers. Today, the industry is experiencing exciting and exponential change, as technologies such as artificial intelligence (AI), robotics, and Internet of Things (IoT) are rapidly changing the workplace. While some predicted that these new technologies would eliminate jobs, we have found the reverse—more jobs are actually being created.

The availability and attractiveness of mechatronics training and engineering degrees can provide a two-fold benefit to the manufacturing industry. First, it can entice students and younger workers to consider working in fields and industries they would not have otherwise considered. And more importantly, it can prepare them for the types of jobs that manufacturers are having the most difficulty filling — those that require a multidisciplinary approach to engineering, marrying traditional mechanical and electrical concepts with practical knowledge of software, motion control, sensors, and networking.

Leave a Reply

You must be logged in to post a comment.