Piezo elements are ceramics that change shape when subject to electricity or (when subject to mechanical loading) output electricity. Manufacturers process and press plumbum, zirconate, titanate (PZT) powder together and fire it into a quartz. Then they integrate the ceramic with ferroelectric material to make electrodes. Finally, manufacturers apply electromagnetic fields to the piezo elements […]

FAQs + basics

What are shock and vibration absorbers? A technical summary

Motion is present in almost all industrial automation systems. Stopping or changing the direction of that motion releases kinetic energy, which can cause shock and vibration to occur. Any sudden shock in a system can cause immediate damage to the overall machine and the components it may be manufacturing or processing. And consistent vibration inputs […]

FAQ: Where do brush dc motors still make sense?

Brush dc motors are a mature technology that’s been around for more than a century. So with brushless motors and an ever-increasing array of controls for all motor types, why do engineers still use brush motors? After all, it’s common knowledge that brush motors exhibit wear at their brush-and-commutator interface. The truth is that brush […]

What are rack-and-pinion sets? Technical summary

Updated May 2016 || Options for linear motion abound, but today’s rack-and-pinion sets are precision mechanical devices that in some cases deliver performance rivaling that of electromechanical alternatives. First modernized 150 years ago to drive railway trains up steep passages, rack-and-pinion sets today are useful in everything from small consumer devices that move a few […]

What is a gearmotor? Technical summary for engineers

Updated May 2016 || By Miles Budimir • Senior Editor Gearmotors are a fairly well-established technology. And recently, there is renewed interest in gearmotors, following a trend in integrated systems in general. More specifically, rising energy costs are driving demand for improved process efficiencies. This presents an opening for gearmotors that can be used in […]

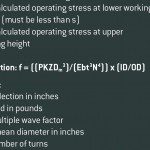

Wave spring sizing and selection

Although wave-spring applications abound, there are basic rules to define spring requirements and determine whether a design can use a stock or standard spring or needs a special wave spring. The first and most important consideration is the load the application will apply to the wave spring. Required load is defined as the amount of axial […]

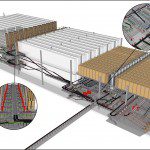

Basics of conveyors: Technical summary of industrial material-handling options

Updated August 2019 || Conveyors are automated tracks that move bulk material or discrete products from one area to another. They’re the backbone of myriad material-handling applications to improve efficiency and throughput. Recent advances in materials, controls, and modular subcomponents have spurred new large conveyors for bulk material transport, miniature conveyors for discrete sorting, and […]

Couplings for PT and motion designs: Technical Summary

Updated May 2015 by Mike Santora || Couplings are devices that connect two shafts for transmission of torque from one to another, usually on rotating equipment such as motors. They should be designed to allow for some end movement. Two types are available — rigid and flexible. Flexible couplings compensate for misalignment, while rigid couplings work […]

What are Positioning Stages and Tables? Technical Summary

Updated May 2015. || Positioning stages and tables are used in motion control systems to hold down a work piece or position it for some operation. Stages or tables, whether linear or rotary, are most often complete motion sub-systems. That is, they are motion systems themselves comprised of components such as linear motion elements, motors […]

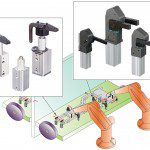

What are Grippers and End Effectors? Technical Summary

Updated December 2015 by Lisa Eitel || In robotics and material handling, end effectors are tools or devices connected to the end of a robot arm that accomplish some task. End effectors can be a range of types, including cutting tools and drills, welding tools, brushes, screwdrivers, vacuum cups and grippers. Grippers are devices often used with […]