In this two-part article, we cover the products, materials, and features that designers and engineers should specify when choosing motion components for cleanroom environments. In part 1, we looked at how to reduce particle generation due to friction between moving components. In this second part, we’ll look at another source of contamination — outgassing — […]

Linear Motion

How to specify motion components for cleanroom environments: Part 1

In this two-part article, we cover the products, materials, and features that designers and engineers should specify when choosing motion components for cleanroom environments. In part 1, we look at how to reduce particle generation due to friction between moving components. Designers of automation systems are tasked with many competing demands, such as balancing cost and performance, […]

How does stiffness affect piezo output force and displacement?

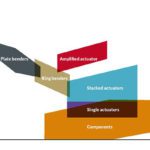

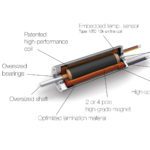

Piezo actuators operate on the inverse piezoelectric effect: when voltage is applied, the actuator contracts or expands. But when the actuator is blocked from moving (by a load applied in the direction of travel), it generates a force. This relationship between displacement and force in piezo materials is an inverse relationship. In other words, the […]

How do rotary voice coil actuators work?

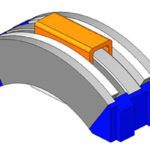

Most linear motion devices have a rotary equivalent, and voice coil actuators are no exception. While the versions depicted in most product images and videos are linear, rotary voice coil actuators fill a need for smooth, arc-shaped motion and torque production with fast response times. But unlike the design relationship between rotary and linear motors, […]

Electric motors: Trends in stepper, battery-powered, and integrated motion designs

Updated November 2019 ⚙️ From induction motors in electric vehicles to tiny coreless dc motors in drug-delivery equipment, electric motors continue to proliferate. Last year we saw consumer products, implantable medical devices, and automation of previously manual tasks spur the most innovation in motor design and use. This year those trends continue — and now […]

Engineered materials and upfront design work (are leading trends for mechanical components)

Seals, chains, cable carriers, springs, retaining rings, and general power-transmission (PT) components continue to see new materials at critical surfaces; proliferation of application-specific versions (especially for compression and wave springs); and increasingly practical online purchasing for both off-the-shelf components and customized orders. Here we explore some of these trends. Online B2B ordering of very specific […]

SERAPID supplies Meridian Lift for XXIII Olympic Winter games opening ceremony

The SERAPID solution has once again been chosen to provide dynamic stage action for the opening ceremony of the 2018 Olympic Winter Games in Pyeongchang, South Korea. SERAPID had previously provided an extensive stage lift system for the 2008 Summer Games in Beijing, China. The opening ceremony took place in the Pyeongchang Olympic main stadium, […]

SERAPID Group (lift and transfer-system supplier) launches new website

SERAPID Group — a leading supplier of lifts, quick die change, and horizontal transfer systems — has launched its new website at www.serapid.com. “We are proud to provide customers with a new and improved website,” said SERAPID Group Chief Operating Officer Guillaume Davies. “With this new site we aim to create an exciting experience for visitors […]

Video illustrates smart linear actuator benefits for automation applications

Thomson Industries Inc. has released an educational video (below) that summarizes the benefits of smart actuators, which feature integrated electronics. The five-minute video explores how smart electromechanical actuators are meeting demands for greater connectivity, application flexibility and cost efficiency, and illustrates their use in factories, on- and off-highway vehicles, and structural automation. In discussing the […]

Belt drive axes can reduce automation costs

Mechanical engineers often need a basic, space-saving linear guide when designing technology that performs simple tasks, such as vending machines. Since such technology does not handle high loads, high speeds or high positioning accuracy, intricate linear guides are not necessary. However, most solutions on the market are very advanced, leaving manufacturers forced to either pay […]