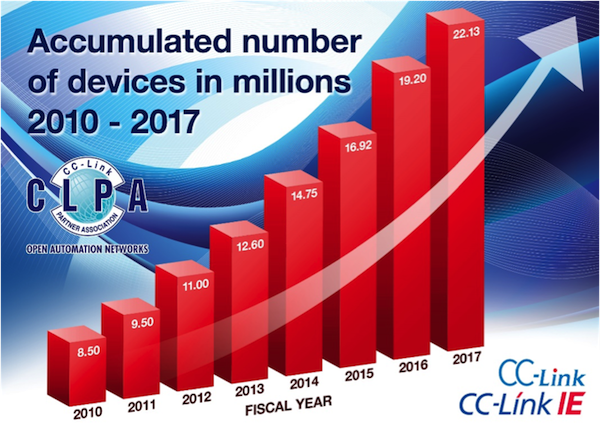

The number of devices communicating via the open CC-Link IE Ethernet and CC-Link Fieldbus networks passed the 22 million mark in 2017, confirming their position as one of the fastest rising industrial network technologies globally. Having posted an increasing annual growth figure of over 2 million every year for the past four years, the governing body – the CC-Link Partner Association (CLPA) – is predicting that number will comfortably exceed 24 million sometime during 2018.

The number of devices installed annually, equipped with CC-Link fieldbus or more recently the increasingly popular CC-Link IE gigabit Ethernet, has been constantly expanding since the foundation of the CLPA, back in 2000. By 2017 the annual growth rate had reached over 15% adding nearly 3 million nodes when compared to the previous year’s figures.

A key feature that has made CC-Link IE and CC-Link industrial automation network technologies so popular is their open status. Users are not limited to one single automation hardware vendor or a small number of control and automation equipment suppliers. Instead, machine and system builders can select components from an ever-expanding pool of CLPA partner companies and be sure that these products are compatible and easy to integrate.

John Wozniak, P.E., Manager of CLPA-Americas, explains: “The increase in the number of CC-Link IE and CC-Link devices is a result of the growing number of CLPA partners.” Currently, there are over 3,400-partner companies worldwide and more than 1,800 certified products available from over 300 manufacturers.

The CLPA’s solutions are a de facto standard in Japan and other parts of Asia which helps boost the total figures. However, usage is not limited to this market and adoption is growing here in the Americas as well as Europe. Acceptance has been helped recently by an interoperability specification developed between the CLPA and PROFINET & PROFIBUS International (PI).

An additional development that has benefited CC-Link IE end users is a collaboration between the CLPA and the OPC Foundation (OPCF), which resulted in the development of an OPC UA companion specification for the CLPA’s CSP+ for Machine technology. This increases process transparency and simplifies the configuration and maintenance of plant systems by treating complete machines as single devices.

John Wozniak adds: “The Partner Association is committed to providing its users with access to solutions that help with achieving the goals and objectives required by Industry 4.0. The CLPA has been leading the way in industrial networking cooperation, which has allowed our users to benefit from a wide range of open and flexible solutions from many manufacturers, developers and integrators. We firmly believe this is one of the main reasons why we are continuing to attract more and more support for our technologies from industry.”

Leave a Reply

You must be logged in to post a comment.