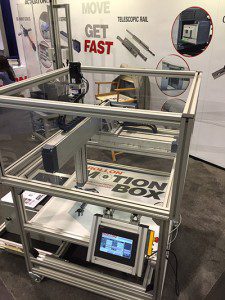

I had a great chat recently with Mark Cone of Rollon Corp., and got to see their new motion box in action. The box is a 3-axis Cartesian motion system, so it’s a turnkey motion platform with actuators, closed loop servo-system, a complete electrical enclosure with 3-axis motion controller, HMI, brackets, cable carrier, and motor mounts.

I had a great chat recently with Mark Cone of Rollon Corp., and got to see their new motion box in action. The box is a 3-axis Cartesian motion system, so it’s a turnkey motion platform with actuators, closed loop servo-system, a complete electrical enclosure with 3-axis motion controller, HMI, brackets, cable carrier, and motor mounts.

“The customer just has to add on the interim tooling and the framing—whatever they’re going to mount it to. Then, they’re off and running,” Cone said. “All the design work and all the sizing work and all the product selection of the motion system or the motion platform, is all done for you. It is pre-engineered, ready to go.”

I asked Cone if there were any particular applications or industries that Rollon was going after with this motion box.

“Pick and plays, dispensing … for instance, we had a customer come by the [MD&M West] show today and he has some fasteners that he’s trying to insert into an array, like a 15-in. x 15-in. array, and he wants to automate that process. So with this motion box, he can buy this turnkey for $35,000 and he can add on his interim tooling, his feeder to de-feed the dispensers, and he can buy some 8020 framing, for instance, and put this on an aluminum frame, and he’s ready to go for his process. A little programming and he’s got an automated production process application,” he said, “It’s perfect for that kind of customer that can do a little bit of integration, themselves, in house, but just needs to get further along in their process, so they don’t have to get all the parts together and engineer the whole thing.”

Leave a Reply

You must be logged in to post a comment.