With the advent of the coronavirus pandemic, there has been a surge in interest in automation across many industries. As demand for automation has increased, suppliers of automation components such as motors, drives, and controllers are seeing increased demand as well.

Controllers and drives on offer today are more powerful and offer better performance than ever before, with more built-in functions adaptable to a range of diverse applications. Performance improvements for controllers and drives rely in large part on advances in electronic circuitry; specifically, microchips. These devices are at the heart of automation and motion control and as the world has seen in 2021 with the consequences of the coronavirus pandemic, shortages of microchips have impacted many industries and products. And with the prospect of continued supply chain issues into 2022, some motion control suppliers are giving their customers a heads-up to plan for long lead times, up to 6 to 12 months in some cases.

Precision motion control supplier Nippon Pulse sees an unpredictability as to where the chip market inventory and pricing is headed. The company reports that with the continual expansion and demand of cloud services (not only Microsoft AZURE, Amazon Web Services and Google, but also IBM and Apple), this will put a huge demand on higher-performance and high-volume CPU fabs. As for Texas Instruments (TI), they say they are heavily invested into new capacity to meet the market demands – with higher throughput already planned for this year.

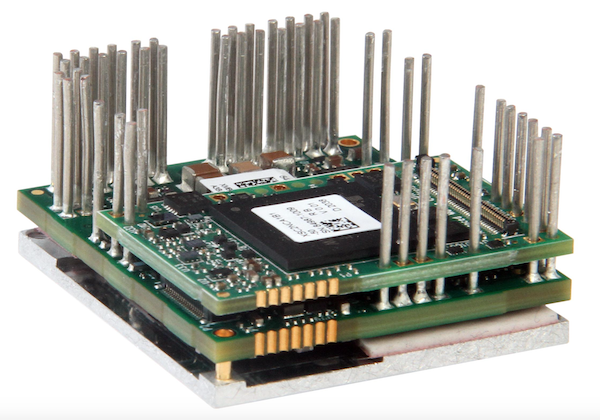

The focus for Advanced Motion Controls is on identifying and integrating replacement components that are unavailable or in short supply. With 2021 going down in history as the year of the chip shortage, those in the industry expect to still be dealing with the effects well into 2022.

High demand for controllers and drives continues in a number of application areas, including most notably robotics. For example, TI is seeing a high demand for drives, PLCs and control solutions with the rapid growth of logistics robots, warehouse automation and transportation. The personalization of end-products requires flexible manufacturing, which results in complex motion controllers.

The boom in logistics and automation during the coronavirus pandemic has increased demand in robotics and motor drives. In factory automation, cobots and automated guided vehicles are becoming smarter and used more widely – increasing efficiency on the factory floor.

Likewise, Advanced Motion Controls sees mobile robotics and electric mobility leading the charge when it comes to pushing the envelope for new innovation in servo drives. This includes warehouse and factory automation as well as automation in people-centric industries like grocery stores, shopping malls and hospitals.

A parallel driver across much of industry is data; specifically, big data and its relation to the IoT and Industry 4.0. From TI’s perspective, Industry 4.0 is driving products to become smarter, making connectivity especially important. Data is crucial to the successful operation of smart factories, machine health, monitoring and more, which requires high data throughput – both wired and wireless – while maintaining and optimizing size and efficiency. It is also crucial that the embedded processors in these systems can process data at high speeds and low power for overall system efficiency.

Given the demand for more data with the IoT and Industry 4.0, functions and features that enhance data transmission are crucial. For instance, TI is seeing a higher demand for functional safety and secure communications, with real-time functionality and quick response time becoming more critical. Data rates are increasing as the demand for data grows. In most industrial applications, Ethernet and industrial protocols are used. The company is working to define and standardize industrial, real-time communication to achieve the best interoperability – aiming for more data throughput while also maintaining low and deterministic latency.

At Advanced Motion Controls, the company is working on its Dual Universal Feedback concept. This is the combination of Dual Feedback with Universal Feedback; in simple terms, it provides the ability to process data from two encoders of any type.

Dual Feedback means the servo drive can accept two encoders. This is used in dual-loop control configurations to increase the accuracy on machines that have backlash. One encoder is placed on the motor to ensure smooth, controlled velocity even when the load changes due to backlash. The other encoder is placed on the load to ensure precise positioning at the load regardless of backlash or when there are non-rigid transmission components. The main advantage is that Dual Universal Feedback gives engineers and system designers more flexibility with how they set up the feedback in their system.

Leave a Reply

You must be logged in to post a comment.