Michigan-based Byrne Electrical Specialists designs and manufactures power and data technologies for office, teaching, and hospitality environments. Recently, the company began using industrial conveyors from QC Conveyors to increase their throughput of electrical outlets.

A trio of robotic assembly cells — each with its own threesome of busbar conveyors and solo output conveyor — build electrical outlets for modular office furniture. Then one packaging cell at the end of the line collects the output from these assembly-cell feeds for final testing and shipping.

1. Operators set the parameters for the current job via a human machine interface (HMI) based on the specifics of the current order being processed — including parameters such as color, size, needed outlet count per case, and so on.

2. Operators then load the outlets’ front shells and back plates by hand on one side of a machine … and put metal bus bars into hoppers on the other. “Each electric outlet has five parts — including three busbars for line, neutral, and ground. Each busbar has its own hopper and conveyor-based sorting line to let us take these raw components and basically dump them into hoppers. Then each hopper drops busbars onto a cascading three-layer conveyor system,” explained Byrne engineer Dan Wierenga.

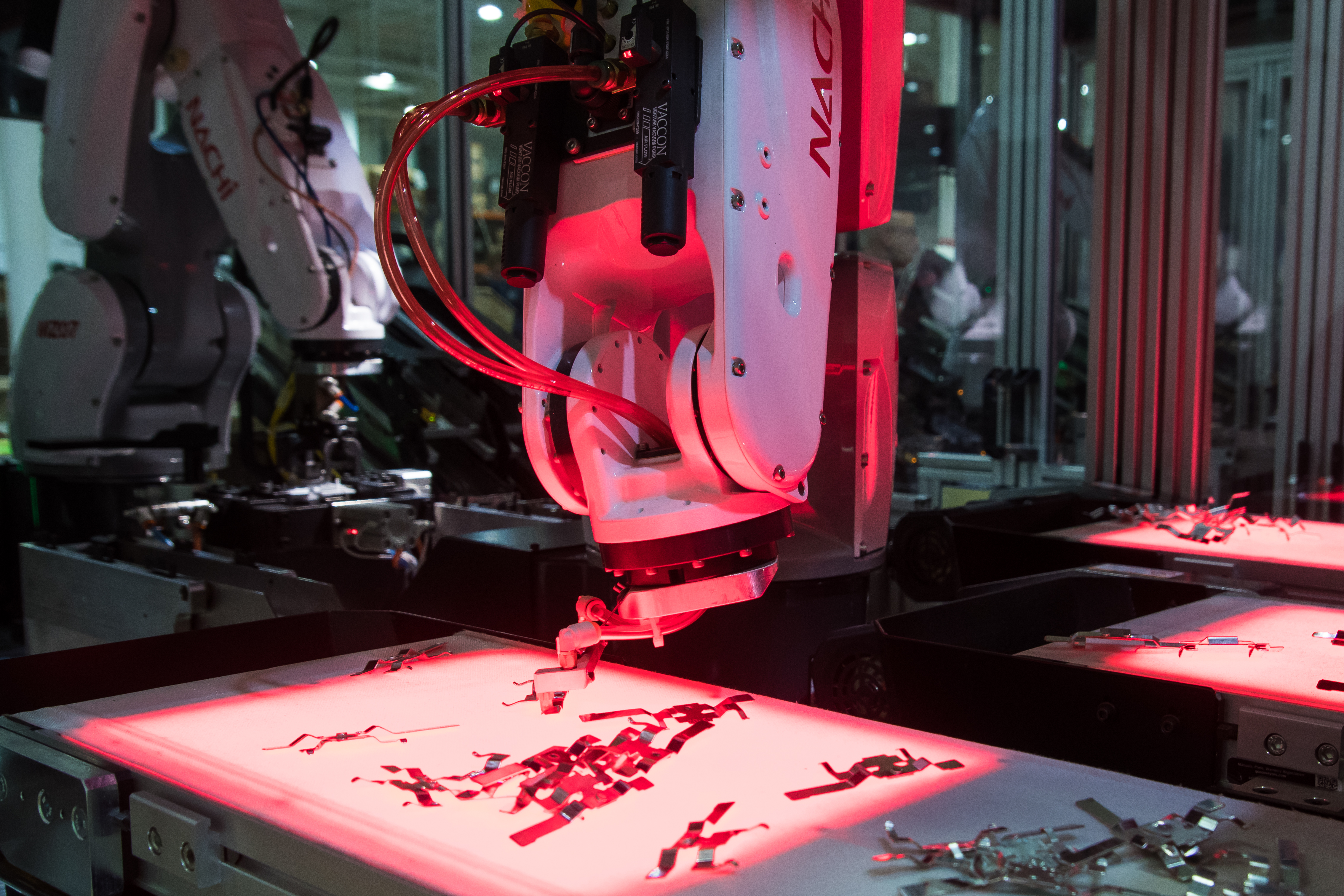

3. The first of the three conveyors moves very slowly and drops busbars onto a faster middle conveyor (in a way that spaces them evenly). In the middle of this conveyor is an underlit section — provided by Spectrum Illumination. The underlit conveyor region is monitored by a Datalogic vision system.

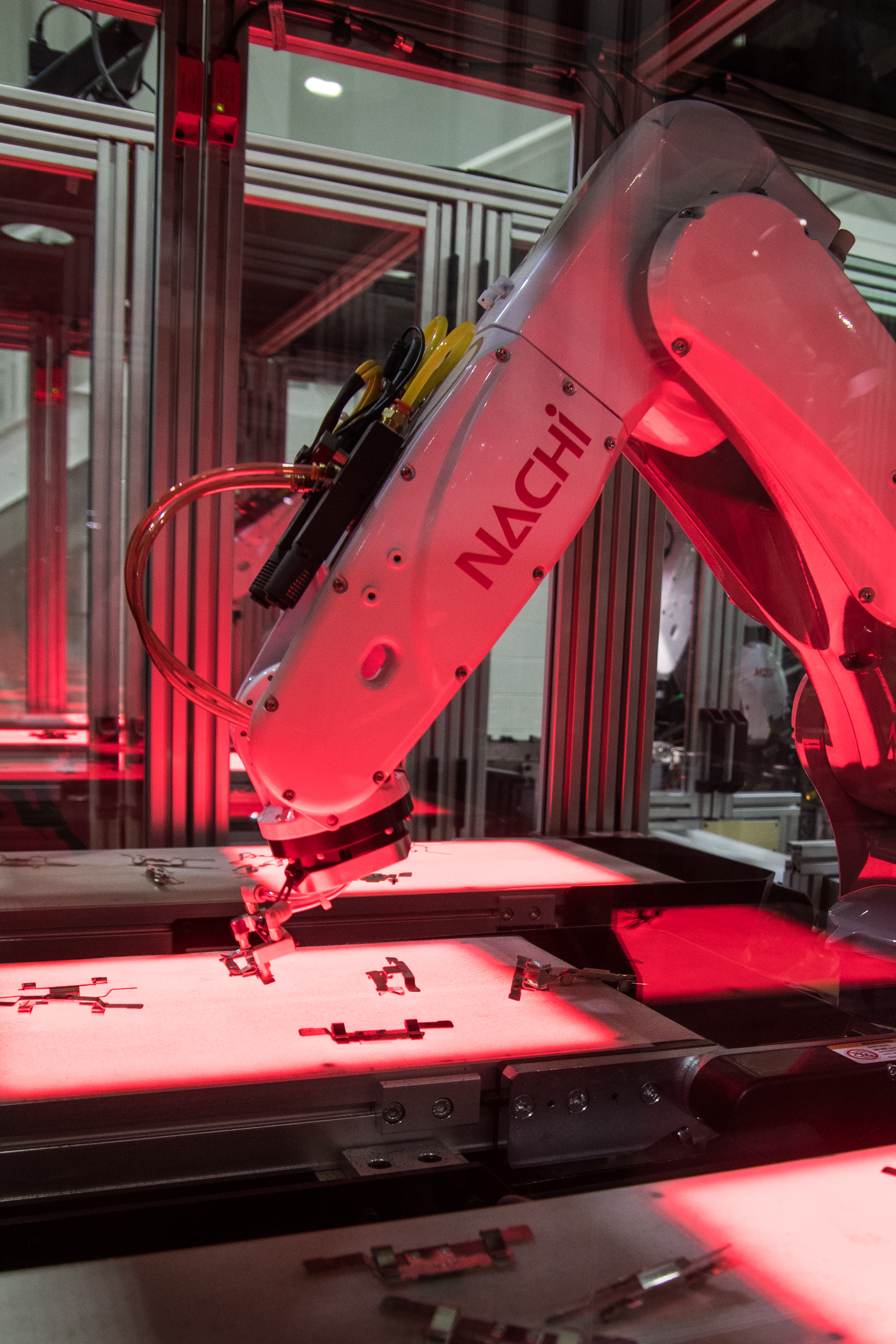

As busbars travel over the underlighting, the vision system confirms they’re right-side up and clear of other parts — and then commands the conveyor to stop to allow pickup by a robot. Any busbars that are bad, misoriented, or clumped together continue onward until they fall onto a third (fastest-moving) conveyor that (via an elevator) returns them to the original hopper. Next a Nachi six-axis robot gets the X, Y, and angle of the busbar, grips and reorients it, and puts it in a holding station.

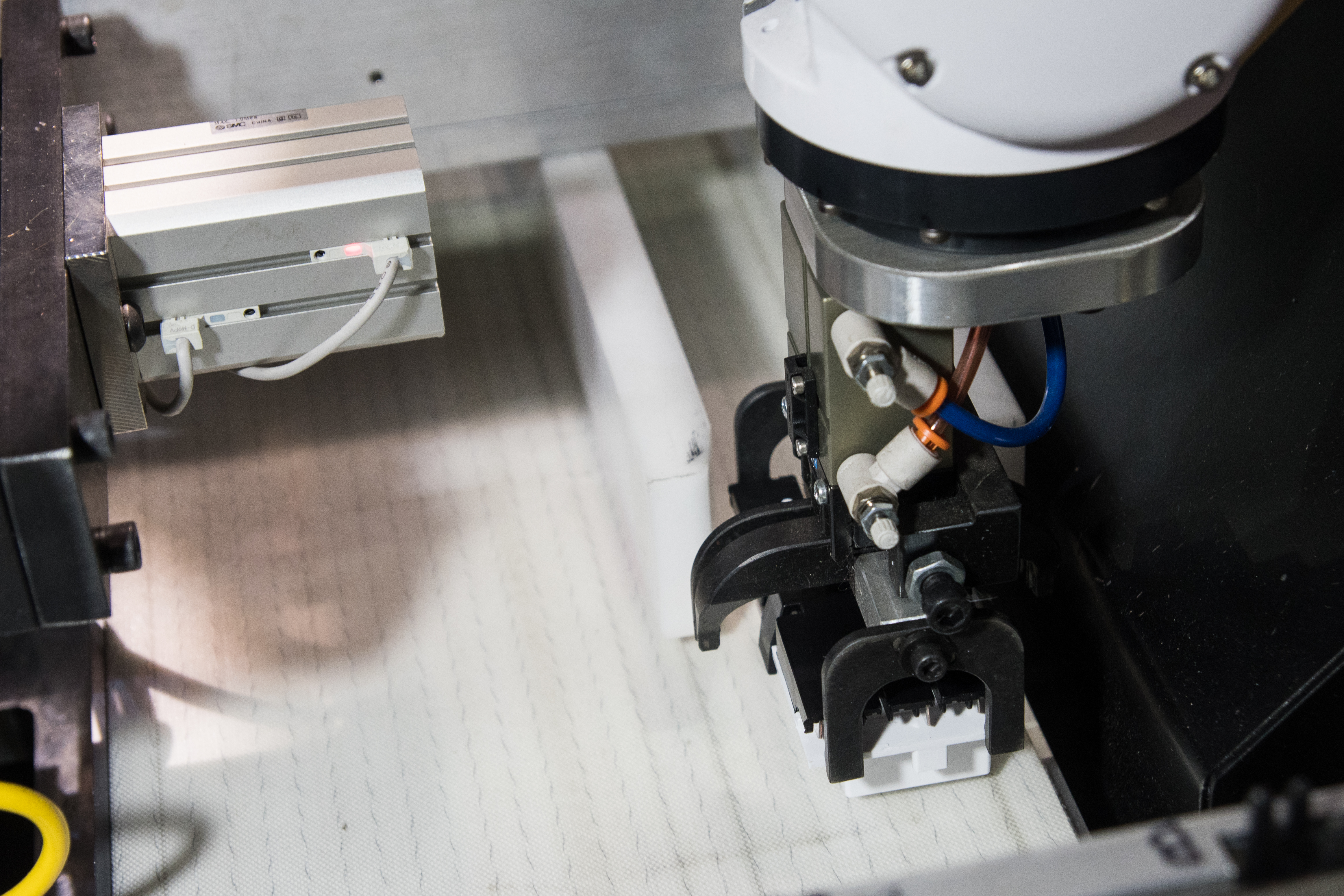

4. Another robot takes the first of two plastic halves — the outlet’s front shell— and puts it into a nest. Then it picks three busbars (readied by the previous robot) and inserts them into the front shell. Then the robot puts the outlet’s back shell half on the front and presses them together. For there, the robot places the completed assembly on another conveyor (from QC Conveyors) to inspection and packout.

5. Finished electrical outlets are lifted off the conveyor and inspected visually on both sides. They then pass an inkjet printer that prints a symbol specific to the current order on the front of the outlet. The printer applies logos in three different colors depending on the outlet’s body color. After printing, all the electrical outlets get a label on the back and then go into the proper case for that order.

The system was designed for Byrne Electrical Specialists by Criterion Manufacturing Solutions, where Wierenga worked during the installation design before joining Byrne to keep the line optimized. A local QC Conveyors distributor, Industrial Control based in Zeeland, Mich., worked very closely with engineers at Byrne on the design specifications for the automated installation.

“We used QC Conveyors because Byrne has partnered with Industrial Controls on an array of projects before. Plus the conveyors have a convenient form factor and come in custom sizes and lengths — and with an array of belt types,” explained Wierenga. “The latter let us use low-friction belts, transparent belts, and high-durability belts to maximize functionality and lifespan. On QC Conveyors, the belts are also easy to install and replace.”

A major challenge was integrating the moving belt and stopping the belts and then coordinating the vision system’s vision space to real-world robot coordinates. Complicating matters is that the lines must do that for several dozen part variations. “That means we had to design a system that lets us program and calibrate the different parts very easily — which took a fair amount of development,” added Wierenga.

Before this automated machinery, parts were assembled by hand. Each assembler had a manual station where he or she would put the outlet parts together and then weld the part closed. Then the outlets went to another station to get printed and UL testing. All secondary audits, labeling, and packaging after that was manual. In contrast, now Byrne takes raw components and does 100% of its testing, 100% of its parts inspection, and 100% of its boxing for shipment with automation.

“We went from four or five different part handoffs to zero handling of the completed part … and much higher end-product quality,” said Wierenga. For more information, visit byrne.com and qcconveyors.com.

Leave a Reply

You must be logged in to post a comment.