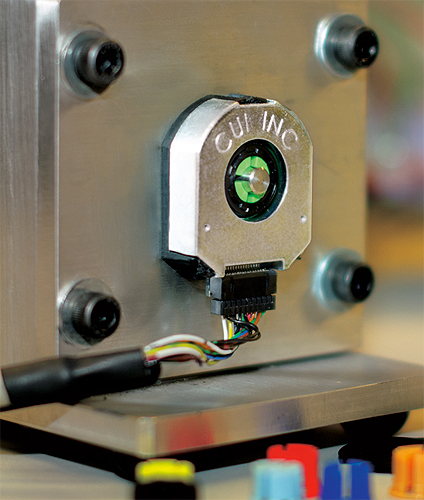

CUI Inc has announced a modular encoder series that uniquely combines both accuracy and ruggedness.

The AMT11 incremental encoder family is targeted at industrial applications, which are subject to vibration and contaminants – such as dust, dirt and oil – that typically stop optical encoders from working effectively. This, when combined with exceptional accuracy figures of +/-5 arcmin, makes the AMT11 ideally suited to automation, robotics, and renewable energy motion-control applications.

Positional information is generated using CUI’s patented, capacitive code generation system coupled with a proprietary ASIC. The device also implements an onboard diagnostic system for use in the field or during development, which is accessible via a serial or CUI’s AMT Viewpoint™ graphical user interface.

Furthermore, the AMT’s modular locking hub design simplifies the assembly process, reducing the time-consuming tasks of mounting and alignment to just a few seconds.

“CUI’s is the only modular encoder technology on the market where users are not forced to trade off accuracy for durability,” stated Jeff Smoot, CUI’s VP of Motion Control Products. “Furthermore, users will be able to benefit from the higher level of intelligence and flexibility that it delivers. And, versus optical and magnetic encoders, the AMT11 provides a unique combination of ruggedness, accuracy, and ease of use that is unrivaled in the industry.”

The AMT11 is available with 20 programmable resolutions with a range of 48 to 4096 PPR, adjustable at the factory or via AMT Viewpoint™. The compact series measures 28.58 x 37.25 x 10.34 mm (1.125 x 1.467 x 0.407 in.) and features an ultra-wide -40~105 °C operating temperature range.

It has a current draw of 10 mA at 5 Vdc, making it ideally suited to mobile and battery-driven equipment, and an input range of 4.5~5.5 Vdc, with options for TTL voltage or line driver outputs.

Additional options include radial or axial connector orientations, 9 mating sleeves ranging from 2 mm to 8 mm, and base plates with multiple pre-drilled mounting hole patters to mate with a wide range of motors.

The AMT11 series is available now through distribution with prices starting at $29.63 per unit. Please contact CUI for OEM pricing.

CUI

www.cui.com

Leave a Reply

You must be logged in to post a comment.