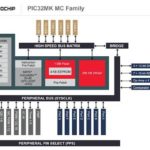

Digital signal processors (or DSPs) are dedicated ICs that can be programmed to execute specific types of calculations or algorithms. They differ from standard microprocessors in that they are not designed to do much if any of the supervisory tasks that microprocessors typically handle. This is why they can execute algorithms much faster than microprocessors or even microcontrollers.

A DSP for motion control is just one that is dedicated to motion control tasks including generating motion profiles or trajectories, closing the control loop, and sending control signals to the motor drive.

DSPs were first incorporated into motion controllers in the early 1990s. They offered the ability to handle complex motion profiles with dedicated processing power. More recently, DSPs have gotten better by offering more in terms of faster processing speeds and generally more functionality in the space of a small IC. This, in turn, has made motion controllers as well as drives smaller and packed with more capabilities.

Leave a Reply

You must be logged in to post a comment.