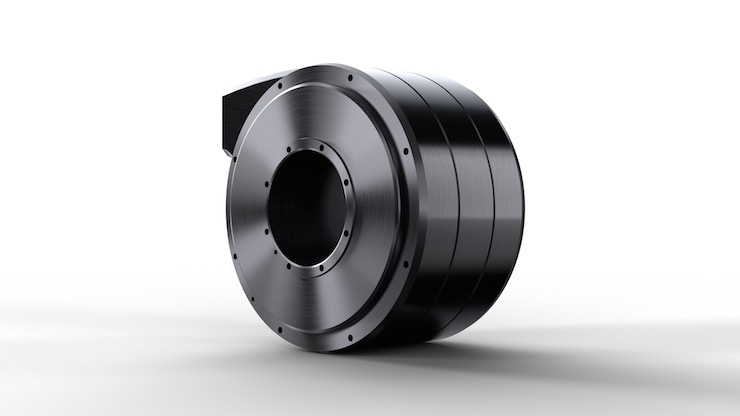

Genesis Robotics & Motion Technologies announces the availability of its new LiveDrive LDD 1800 Series Direct Drive Actuators, with an extensive range of configurations and performance options. LiveDrive direct-drive actuators eliminate the need for gearing and are redefining the next generation of parallel robots and precision machinery, unlocking capabilities beyond the reach of conventional drivetrains, across many applications.

LiveDrive LDD actuators redefine the standard of simplicity, cleanliness, and productivity for high-throughput machines. LiveDrive is a high-torque, compact, direct-drive solution designed for robots and machines in the food, packaging, pharmaceuticals, and electronics industries. LiveDrive reduces maintenance requirements while increasing uptime and reliability. And with no need for gears, belts, or lubrication, LiveDrive actuators simplify the drivetrain, delivering increased performance and lower total cost of ownership.

“We are thrilled to launch this leading-edge actuation technology, making it available to manufacturers and system integrators globally,” said Chris Di Lello, CEO of Genesis Robotics & Motion Technologies. “A simpler drivetrain empowers a better robot: faster to assemble and easier to maintain. This creates value for our customers and end users and represents a true breakthrough for the robotics and automation industries.”

A LiveDrive LDD 1800 Series actuator is less than half the length of a typical servo-gearhead drivetrain, enabling greater utilization of machine workcells and factory floor space. LiveDrive’s washdown-ready IP67 enclosure – with its smooth surfaces and minimal collection points – allows for easy cleanup. Importantly, LiveDrive actuators do not require a gearbox, removing the risk of oil leakage or contamination. No gearbox means reduced downtime, inspection, and maintenance requirements.

LiveDrive’s direct-drive technology also eliminates backlash and improves system stiffness. Coupled with its higher torque-to-weight ratio, LiveDrive creates opportunities for robot and machine designers to improve performance in highly dynamic applications. LiveDrive, with its low inertia and fast stopping times, supports control system safety to meet Collaborative Robot Technical Specification ISO/TS 15066 and bring human-machine collaboration to new applications.

Genesis LiveDrive LDD 1800 Series Direct Drive Actuators are available with an extensive range of configurations and performance options. Standard models include four sizes, various voltage levels and support integration with third-party servo drives.

For more information, visit www.genesis-robotics.com.

Leave a Reply

You must be logged in to post a comment.