ABM Drives are tailor-made specifically for the application whether it requires compact design, low-noise operation or maximum operating safety. A flexible modular design system allows cost-effective low volume production runs.

Custom motors and drives are available for a wide range of application types: forklifts, electric vehicles, lifting technology, biomass heating systems, textile machines, wind power control, warehouse logistics, high-speed doors, air compressors, construction equipment, packaging machinery and vehicle-inspection equipment. The high overall efficiency of ABM Drives’ helical and parallel shaft gearboxes reduces power input and energy consumption.

All products are engineered in-house. Components that represent a core competence are reliably produced in-house on state-of-the-art machine systems. This guarantees that electric motors, gearboxes, brakes and electronics are perfectly coordinated.

All products are engineered in-house. Components that represent a core competence are reliably produced in-house on state-of-the-art machine systems. This guarantees that electric motors, gearboxes, brakes and electronics are perfectly coordinated.

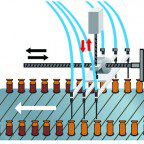

Vertical integration of ABM Drives’ manufacturing includes tool-and-die engineering and aluminum die-casting to guarantee best implementation and integration of components to a compact drive unit. High-quality gearing guarantees quiet operation. Tight-fitting housing covers and flanges prevent distortions that can amplify noise. Aluminum housings absorb harmonics and other vibrations better than cast iron.

A large center distance between the motor centerline and the hollow drive shaft centerline gives the application designer more freedom/clearance to integrate the unit into the application.

Many layouts are possible, from integration of the motor into the gearbox housing, U mounting of the motor, to customizing the output shaft. The end result is a true plug-and-play motor and drive-unit solution designed to save time and money. For more information, visit abm-drives.com.

ABM DRIVES INC. engineers and manufacturers high-performance motor, gearbox, brake and frequency inverter solutions for machines, plants and mobile devices in hoisting technology, warehousing, material handling, electric vehicles, biomass heating systems, wind turbines and many other markets. Founded in 1927, the company belongs to the senata Group. In-house manufacturing includes tool-and-die design, aluminum-casting foundry, CNC housing machining, manufacturer of shafts, cutting of gear teeth, motor development technology, assembly and final testing.

Leave a Reply

You must be logged in to post a comment.