This is Part 2 of a two-part series. You can read the first part here.

Tell us about a new application where engineers used your motion-control and power-transmission components to improve their design. What about this application is unlike anything possible 10 years ago?

Tom Quartararo

Ultra Motion

Another industry trend that has been steadily developing is the replacement of pneumatic actuators with electromechanical actuators. Many machine designers are looking for the controllability, repeatability, and efficiency of electromechanical actuators, with the speed and reliability of pneumatic actuators. In order to address these demands, the Servo Cylinder was developed as a brushless dc actuator with top speeds in excess of 14 in./sec, high acceleration capability, and oversized mechanical components. A successful mode of operation in pneumatic replacement is four preset position mode, where the state of two optically isolated digital inputs corresponds to configurable absolute positions. In many cases this mode allows for drop-in pneumatic replacement with existing control systems, and provides controlled speeds, controlled accelerations, and position repeatability better than 0.001 in. Higher speed Servo Cylinders are currently in development so that more machine designers can realize the benefits of electromechanical actuators in their pneumatic applications.

Aaron Dietrich

Director of Marketing

Tolomatic

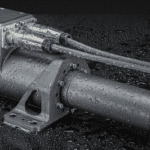

The oil and gas industry has always used hydraulics to automate its valves used in critical applications due to higher forces, longer life and hazardous location requirements. This industry is also very risk-averse and very, very slow to change or adopt new technologies. Now using servo actuator technology, these customers are able to achieve speed and force performance they never thought was possible.

Ben Lutz

LinMot

Our big breakthrough is direct drive linear motion, removing the inefficiencies and imprecision of air without the loss of dynamic movement. For an application like basic part rejection or diversion, rotary to linear systems are too slow, flat linear motors too bulky, and voice coils are too small. The LinMot motor can help OEMs and end users remove air from machines with very little redesign.

One of our second successes is in the capping industry. Previous technology would require a new cam or tooling to be cut for a change in packaging types. Even a small change between package heights would still require the installation of a new cam or fixturing. Our standard linear rotary motor makes changeover between products a matter of changing dimensions from an HMI. Changing form factors with our motors is now the work of a programmer to create a new recipe and test the same day.

Jared Zammuto

Sr. Design Engineer

Warner Linear

We recognized a growing demand for power-dense actuators used in a variety of off-highway and other extreme-duty applications including agricultural sprayers, snow plows, and mower decks. In response, our engineering team developed a completely new, compact electric actuator with self-contained hydraulic actuation that provides the performance of hydraulics without the space requirements and expense of a full-size hydraulic system. With minimal initial drift, once seated, the new, patented H-Track actuator is immune to vibrational drifting and hydraulically self-locks during load reversals, while holding its position without power. This is especially important in applications such as mower deck lifts, agricultural sprayer booms and snow plow blades where the moment force acting on the actuators is dramatically increased due to the constant bouncing that occurs during operation. The actuators unique fluid design allows the unit to withstand sudden impacts, such as hidden concrete parking blocks in a snow plow’s path, without damage to the actuator. These types of encounters can quickly destroy most electric actuators.

David Basken

Misumi

The use of highly engineered coatings in fixture components is rapidly changing. MISUMI introduced a new RDLC coating for locating pins in aluminum body panel assemblies for Body-in-White applications. They eliminated the build-up of the soft aluminum material on locating pins and the fixture-locking

it created.

What kinds of large-scale industry moves are you seeing to miniaturization, System- on-Chip (SoC) technologies, automation, (in the case of electric-motor-driven motion designs) efficiency and customization?

Ben Lutz

LinMot

Almost all servomotors now have plug-and-play technology so when they are connected to a drive their motor characteristics and parameters are preloaded for operation. Many servos use auto tuning that provides general parameters and if you will ‘good enough’ application tuning. Integrated motor/drive designs are still being introduced and are becoming more accepted especially for existing installations where electrical cabinet retrofits are not easy to do and perhaps impossible. LinMot addresses the market with direct drive motor technology to provide the most efficient and most productive method for point-to-point motion thus providing a simple machine design. The linear-rotary motor technology eliminates many mechanical components and allows for a much simpler machine design.

Where do you see the Internet of Things, IIoT, Industry 4.0, or Connected Industry changing motion system design? Where do you see new materials changing motion design?

Aaron Dietrich

Director of Marketing

Tolomatic

This is everywhere and will soon be in all things. All components in the motion system will be connected to the internet of things in the near future, providing more information about what is happening with the motion or the factory, such as diagnostic information on when components need maintenance or failure notices. The sky is really the limit with the low cost DSPs being able to be connected easily to the internet using industrial Ethernet protocols.

Ben Lutz

LinMot

We see remote access for the Internet of Things (separate IP addresses) so that every axis is connected through the plant network increasing uptime and allowing remote access. Monitoring data from the drive allows users to directly predict maintenance intervals by the increase in average current and more accurately

report errors.

Additive manufacturing was used for our USB-Serial converter based on the needs of small batch solution to solve customer’s integration requests from a single tested source.

The newest lubricants have high temperature stability and provide for a wide operating range. All the lubricants LinMot uses are food grade – a big plus to be able to use in and around consumable goods.

Where do you see online configuration tools changing how design engineers specify and buy components? How is your company using software and new forms of connectivity to drive innovation in motion design?

Aaron Dietrich

Director of Marketing

Tolomatic

I feel it’s already there. If you do not have a good online presence and good online tools, customers do not want to do business with you. Online CAD configuration, sizing and selection tools, educational content, e-commerce, and other tools are a must for suppliers to stay current.

Ben Lutz

LinMot

LinMot Designer is also freely available so that any potential user can size their application and directly calculate energy savings. The LinMot website features all the installation guides and CAD models so that parts pass easily from concept to combination. Finally, LinMot Talk configuration software is free online allowing potential users to learn through examples or access existing hardware.

Christopher Morris

Misumi

Not surprisingly, quality, cost, and lead time are crucial elements as engineers begin sourcing a component supplier. A piece often overlooked is the ease of obtaining CAD models. One of the least exciting aspects of mechanical design is researching and procuring CAD files for purchased components. Many times this involves browsing several vendors’ sites, downloading, importing, and constraining CAD files. This is a process that is commonly repeated multiple times through each design revision.

MISUMI has been working extensively on a free CAD add-on suite dubbed Rapid Design. The first of five applications, inCAD Components, allows users to manipulate MISUMI’s configurable components, research pricing, and access technical information – without going to the website. Independent testing has found this tool to reduce the typical design phase by 32%.

You can read Part 1 of the series here.

Leave a Reply

You must be logged in to post a comment.