Engaging individual polyethylene sheet rolls with no system downtime is accomplished with speed and accuracy using Miki Pulley CSZ Clutches. Continuously operating via servo motor power by way of a V-belt, individual roll spools automatically switch on/off as programmed when engaged by the CSZ clutches.

These high-performance clutches function using electro-magnetic force generated by an energized coil which provides physical engagement of input and output members of the clutch. They provide an efficient connection between system motor and load with low inertia, minimal drag, and zero backlash.

Miki Pulley CSZ Clutches feature an integrated bearing design making mounting fast and easy while ensuring application concentricity and excellent system runout. The clutch is designed as a single unitized assembled part, with pre-set factory air gap. Also important, CSZ Clutches operate well in temperatures from 14 to 104°F (-10 to 40°C).

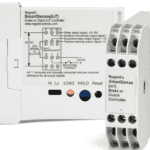

The clutches are available in bores ranging from 10 to 15mm, with brake torques ranging from 1.77 to 7.376 ft. lbs. (2.4 to 10 Nm). The CSZ use corrosion resistant materials and are RoHS compliant like all other Miki products.

For more information about Miki Pulley CSZ Clutches and their application advantages, visit www.mikipulley-us.com.

Leave a Reply

You must be logged in to post a comment.