The BXR-LE brake series from Miki Pulley is a power-off, engaged brake design. When the stator is energized, the brake is disengaged allowing free rotation. When no current is applied, compression springs halt the brake rotor thereby stopping the input shaft rotation. This is an ideal feature to prevent rotation during power failure events. The brakes safely hold a static position, without the need for external power.

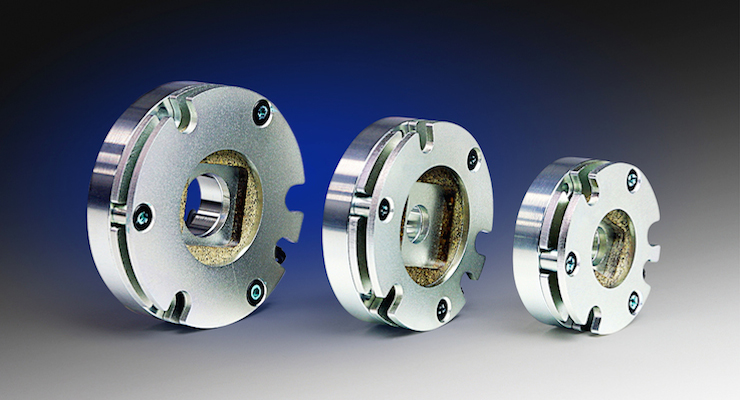

There are six total size configurations in the BXR-LE series to choose from, all of which are designed for smaller machine and robotic applications, where cantilevered loads can negatively impact operation.

These brakes have a slim design and high holding torque in a compact package, and provide quiet operation with long service life. The brake’s unique compact and lightweight design optimizes machine design efficiency. With accompanying voltage controller, power consumption is stepped down to 7 Vdc after a split second of 24 Vdc for brake actuation.

Compared to the other brakes in the broad Miki lineup, the revolutionary BXR-LE design provides just one-third power consumption and heat generation in one-half the overall size thickness of comparable brakes on the market. Specifications are:

- Maximum RPM: 6,000

- Static friction torque range: 0.06 Nm to 3.20 Nm (0.044 ft-lbs to 2.36 ft-lbs)

- Ambient operating temperature: -20 ˚C to 60 ˚C (-4 ˚F to 140 ˚F)

Typical servo motor applications include: robotic arm joints to stop movement during a catastrophic power failure, Z-axis ball screw brakes on 3D printers, pan/tilt brakes for security cameras, brakes for locking sensor alignment and many more.

For more information, visit www.mikipulley-us.com.

Leave a Reply

You must be logged in to post a comment.