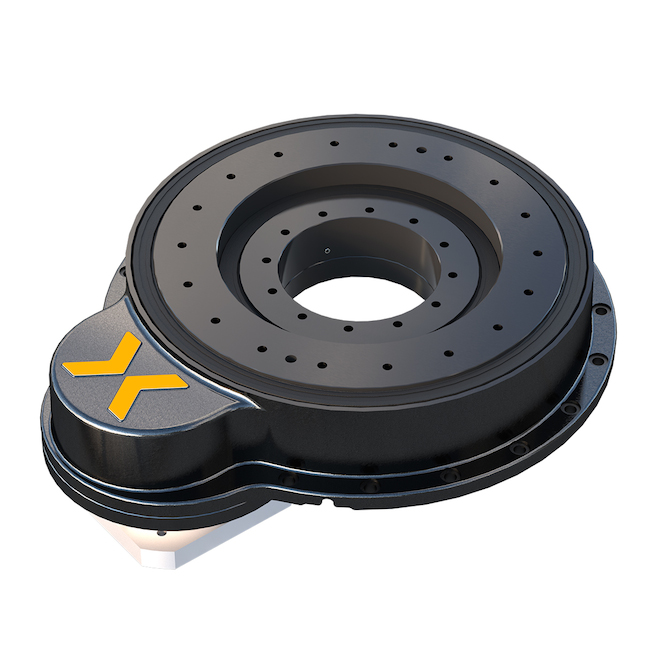

Nexen’s Motor Ready Sealed (MRS) precision rotary indexer maintains the benefits of the company’s existing patented precision roller pinion drive design – zero backlash, high precision, high torque, and high acceleration – while delivering significant new benefits. A high roller pinion-to-gear ratio lets designers direct drive the system with the addition of a servo motor – eliminating the cost of a reducer. This also reduces engineering and installation time. For high-load applications, the designers can drive the system with a reducer/motor combination. The gear-to-pinion reaction loads are fully supported so the servo motor shaft is not subjected to radial loading, which eliminates the need for costly high output capacity reducers in high load applications. All of these features reduce engineering and installation time.

Highlights of the MRS precision rotary indexer include:

- High indexing precision – one-way positional accuracy up to ± 31 arc-sec and one-way repeatability up to ± 5.2 arc-sec

- Zero backlash – unlike other drive systems there is zero backlash from the motor through the driven load

- Acceleration – up to twice as fast as other technologies

- High speed – up to 304 rpm

- Motor/gearbox ready for faster installation

- Sizes: 150, 250, 350 mm output bolt circle diameter, with large open center to optimize performance in small spaces

- Fully sealed, IP65 rated

- Low maintenance and long life

The MRS is suitable for precision rotary indexing applications such as machine tool, and semiconductors, robotics, automated welding, medical packaging, assembly, cutting systems.

For more information, visit www.nexengroup.com.

Leave a Reply

You must be logged in to post a comment.