In a DC motor, the relationships between voltage and speed and between current and torque are straightforward.

When the load (torque) on the motor is constant, speed is proportional to the supply voltage. And when the supply voltage is constant, speed is inversely proportional to the load (torque) on the motor.

Specifications for DC motors include two voltage parameters: nominal voltage and a range of operating voltages. Nominal is the recommended voltage at which the motor should be operated, although the motor can be run with a voltage that falls anywhere within the specified range.

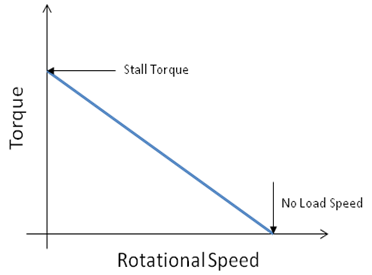

Nominal voltage is a key parameter for DC motors. In fact, a motor’s torque-speed curve is based on its nominal voltage. The slope of the torque-speed curve is determined by dividing the no-load speed of the motor by the stall torque. No-load speed is the speed at which the motor turns when running at nominal voltage and without a load. Stall torque is the maximum torque produced by the motor when running at nominal voltage. (The term “stall torque” is used because it occurs when the motor has zero velocity—i.e., when it is stalled.)

Image credit: National Instruments Corporation

No-load speed: The speed at which the motor turns when running at nominal voltage and without a load (zero torque production).

Stall torque: The maximum torque produced by the motor when running at nominal voltage.

Other parameters that are given at nominal voltage include:

Nominal speed: The speed achieved when the motor operates at nominal voltage and nominal torque at ambient temperature (typically 20 to 25 degrees C).

No-load current: The current the motor draws when operating at nominal voltage and with no load (zero torque production).

Operating a motor at a voltage below nominal generally has no detrimental effect on performance. In fact, running a motor at lower than nominal voltage (and, therefore, slower than nominal speed) can result in less brush and commutator wear (for brushed motors), lower current consumption, and longer motor life. On the other hand, running a motor at a voltage higher than nominal increases current draw and can cause the motor coils to overheat, decreasing motor life.

Leave a Reply

You must be logged in to post a comment.