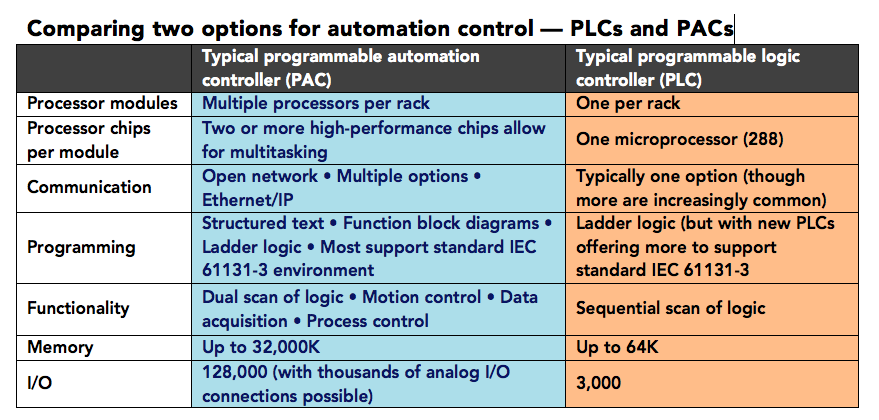

By Steve Meyer || All programmable controllers (PACs) are capable of performing as PLCs but strictly speaking, PLCs can’t work as PACs. That’s because PACs are a superset of PLC-type controls that work when a design needs:

• Multiple channels of communication

• High data traffic

• Coordination with intelligent subsystems

Most high-performance PLCs can host intelligent processors in their backplanes (such as Ethernet modules with multiple ports for expanded data and communications). But such setups are usually expensive. That’s because vendors’ proprietary backplanes and internal operating systems are relatively expensive.

PACs evolved as an option for complex control when microprocessors with significantly more performance became affordable and widely available.

Programmable controllers emulate traditional relay controls

Programmable controllers directly emulate the behavior of electric relay control systems.

Relay logic executes in a rigidly sequential fashion that’s repeatable and rugged enough to survive dirty plant conditions. Each rung of logic is defined by inputs and outputs which are logically connected and which cannot be acted upon without meeting the precise conditions of the circuit logic.

The next rung of logic can’t execute without all the preceding conditions being met. Extra left-hand power rails for loops and jumps were developed to extend the capability of the relay system to create very complex logic. But as these systems became larger and more complex, the cost of creating and maintaining them became unwieldy.

The next rung of logic can’t execute without all the preceding conditions being met. Extra left-hand power rails for loops and jumps were developed to extend the capability of the relay system to create very complex logic. But as these systems became larger and more complex, the cost of creating and maintaining them became unwieldy.

To create the first PLC in the late 1960s, the available electronics had to duplicate the behavior of relay systems — plus be programmable instead of hardwired. This required proof of repeatability and reliability on the plant floor. Custom memory boards, logic controller boards, backplane interface to input and output modules and heavy duty circuitry was required for the PLC to operate in industrial environments.

The notion of creating a software application letting users write application code using the symbols and logic of relays was a new concept.

PLC setups yield to new programmable controllers

As PLCs became widely accepted, the trend has been towards using the platform for more application tasks. PLC functionality has increased dramatically with higher speed, complex math functions and interface with communication networks.

Applications that are highly data-driven aren’t served well by PLCs as the machine control platform. But once PLC behavior was proven reliable on a computer, the PAC was born.

For years in the aerospace and medical industries, the FAA and FDA have mandated that day, date and time-tagged data about the manufacturing process must be stored for extended periods of time.

Today, many manufacturers are finding this type of information a requirement in defending product liability lawsuits as well. But to run predictive maintenance and operational effectiveness programs, controls must provide data. That necessitates more data and complex network interactions — which means PC-based PACs will likely be dominant form of control in the future.

Today, many manufacturers are finding this type of information a requirement in defending product liability lawsuits as well. But to run predictive maintenance and operational effectiveness programs, controls must provide data. That necessitates more data and complex network interactions — which means PC-based PACs will likely be dominant form of control in the future.

Leave a Reply

You must be logged in to post a comment.