Updated May 2019 || Direct-drive motors and gearmotors are often applied to the same types of applications. Both eliminate the need for power-transmission components that unwanted add compliance between the motor and load. This includes components such as belts and pulleys, chains and sprockets, and external gearboxes. Eliminating these mechanical devices (or in the case of gearmotors, integrating the gears for a single motor build) makes for top efficiency.

Gearmotors are typically less expensive than most direct-drive motors. Plus gearmotors offer good reliability and a fairly long useful life, so are applicable to even general-purpose applications.

On the other hand, direct-drive torque motors offer better dynamic performance in terms of higher control-loop bandwidth. Direct-drive motors are relatively costly, though … and so are primarily used in niche applications. But as their cost goes down, direct-drive torque motors will become increasingly competitive with gearmotors.

Application example: Direct-drive torque motors operate in elevators

Elevators from Schindler Elevator Corp. operate in buildings around the world. Motion technology abounds in the elevator shaft, motor chamber, control box, and cab. Now some new installations use direct-drive motors to open and close the doors of the cab and floor being accessed.

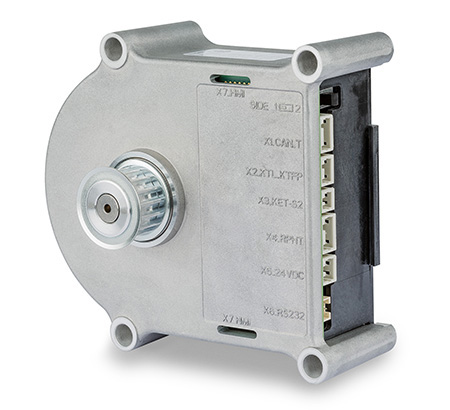

The mechatronic system (called the Door Drive) was developed in partnership with maxon and is based on a flat 90-mm brushless motor and an integrated MILE encoder as well as a customized positioning controller based on maxon’s EPOS2 series. The brushless dc motor system is then encased in a housing for mounting directly to the lift cab.

The Door Drive comes in a powerful version using a belt drive to move doors to 400 kg. A smaller and newer version is a direct-drive variation to save space in applications with doors to 120 kg. The system is power dense, reliable, and intelligent: Upon installation, the Door Drive accepts calibration to suit the elevator and cab type, local safety standards, and size and weight of the elevator doors. For the latter, the Door Drive autonomously optimizes the controls to simplifies technician work.

The motor’s flatness and compactness allows the cab to be bigger. The direct drive also saves energy and while delivering consistent torque output to smoothly move the doors. The integrated controller includes IIoT functionality — collecting operational data for technicians to access.

Leave a Reply

You must be logged in to post a comment.