Edited by Zak Khan || Engineers should give thought to acceleration when starting a stepper motor. Simply programming the controller to advance the motor some steps isn’t sufficient for reliable operation. Programming must also account for stepper-motor construction and operation.

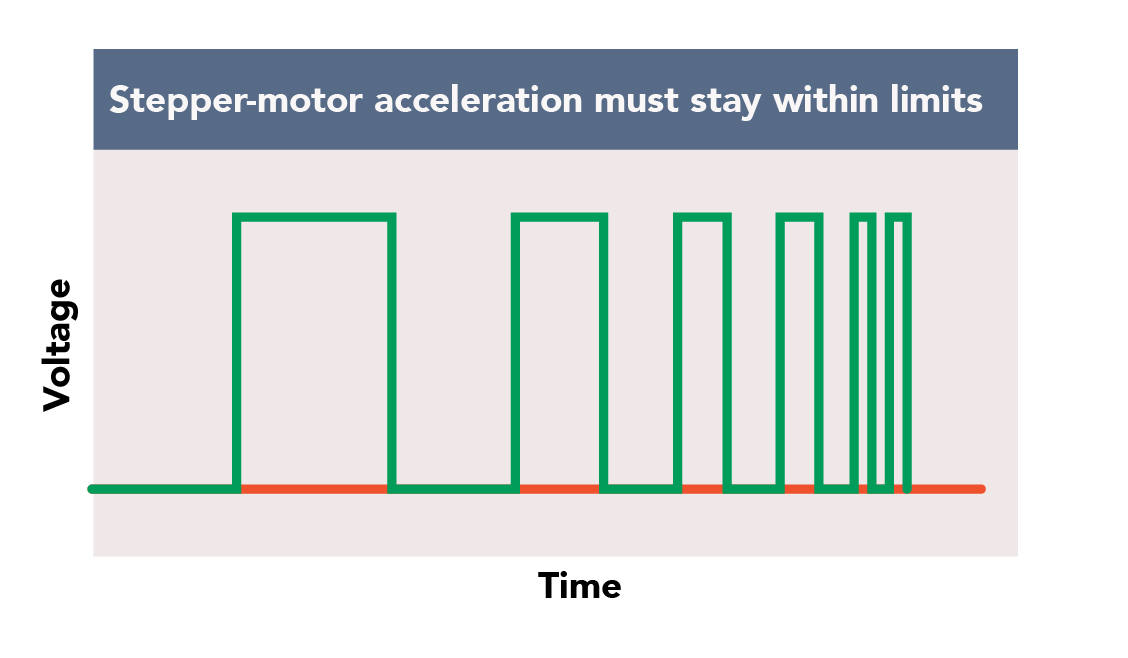

As mentioned in FAQ: How do I prevent stepper motor stalls? and FAQ: How do stepper motors handle inertia mismatch? inertia ratio is critical to stepper motor acceleration. Too great a difference in inertia ratio between system and motor limits rates of acceleration and deceleration … or risk missed steps. So when starting a stepper motor, acceleration and deceleration should happen through pulses to the motor that start slowly and gradually quicken in a process called ramping.

Another consideration when accelerating a stepper motor is current supply. Too little current and too high an acceleration means that the motor won’t have enough power to accelerate both itself and the load it is driving. It may stall if this condition persists. On the other hand, every system has an upper limit of maximum allowable current supply.

Both mean that engineers must consider how realistic a system’s positioning times are. If it requires a too high acceleration in too short a time, it wont be possible to run a stepper motor to a motion profile satisfying system’s requirements.

Algorithms for determining the proper ramping method and subsequent acceleration are complicated, but simplified algorithms exist to aid in design and implementation. Whatever algorithm the engineer uses, it should work well enough to ensure that there’s no lost steps or stalls. Tip: Always perform test runs at whatever conditions and loads your system has before finalizing any design.

Get more information through a PDF download of Applying acceleration and deceleration profiles to bipolar stepper motors — from Jose. I. Quinones for Texas Instruments. Also read the Stepper Motor and Controller Primer from Phidgets.

Leave a Reply

You must be logged in to post a comment.