DC motors can be either brushed type, which are mechanically commutated, or brushless, which are commutated electrically. In brushless DC (BLDC) motors, Hall effect sensors are used in place of a mechanical commutator and brushes.

Hall effect sensors are solid-state, magnetic field sensors. They work on the principle that when a conductor with current flowing through it is placed in a magnetic field, the magnetic field induces a transverse (or sideways) force on the charge carriers, which pushes them to the sides of the conductor—negative to one side and positive to the other side. This buildup of charge on the sides of the conductor induces a voltage. This effect is referred to as the Hall effect, after its discoverer, Edwin Hall.

Image credit: Honeywell International Inc.

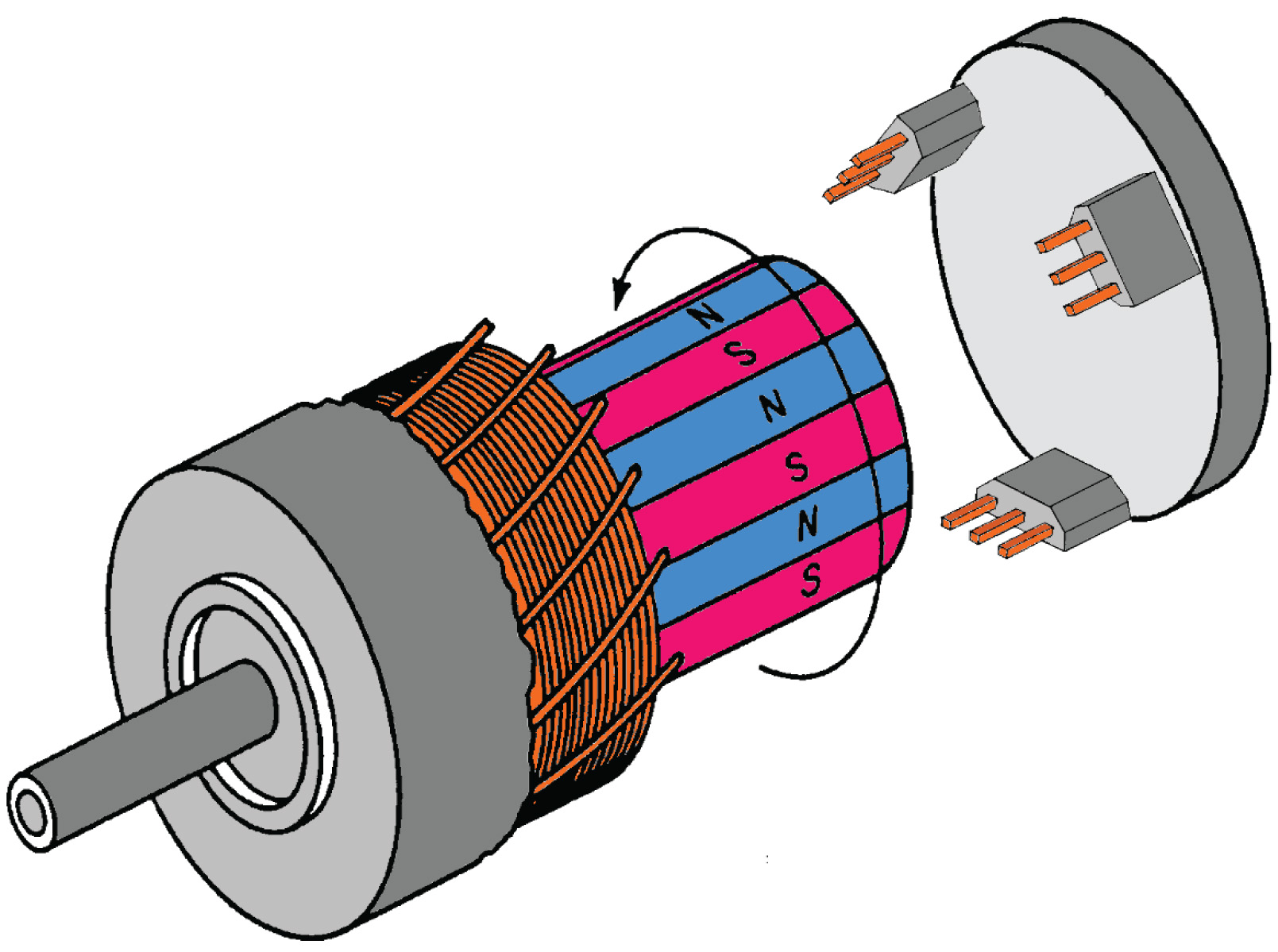

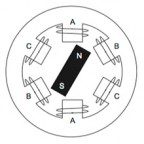

The purpose of commutation, whether by mechanical or by electrical means, is to energize the stator windings in a certain sequence, with one winding positive, one negative, and the third one powered off. Torque production is caused by the attraction and repulsion between the stator field and the permanent magnets of the rotor. Maximum torque is achieved when these two fields are oriented at 90 degrees to each other, and torque diminishes as they fields align. Therefore, in order to keep the motor turning, the stator’s magnetic field should change position as the rotor field “catches up” with it.

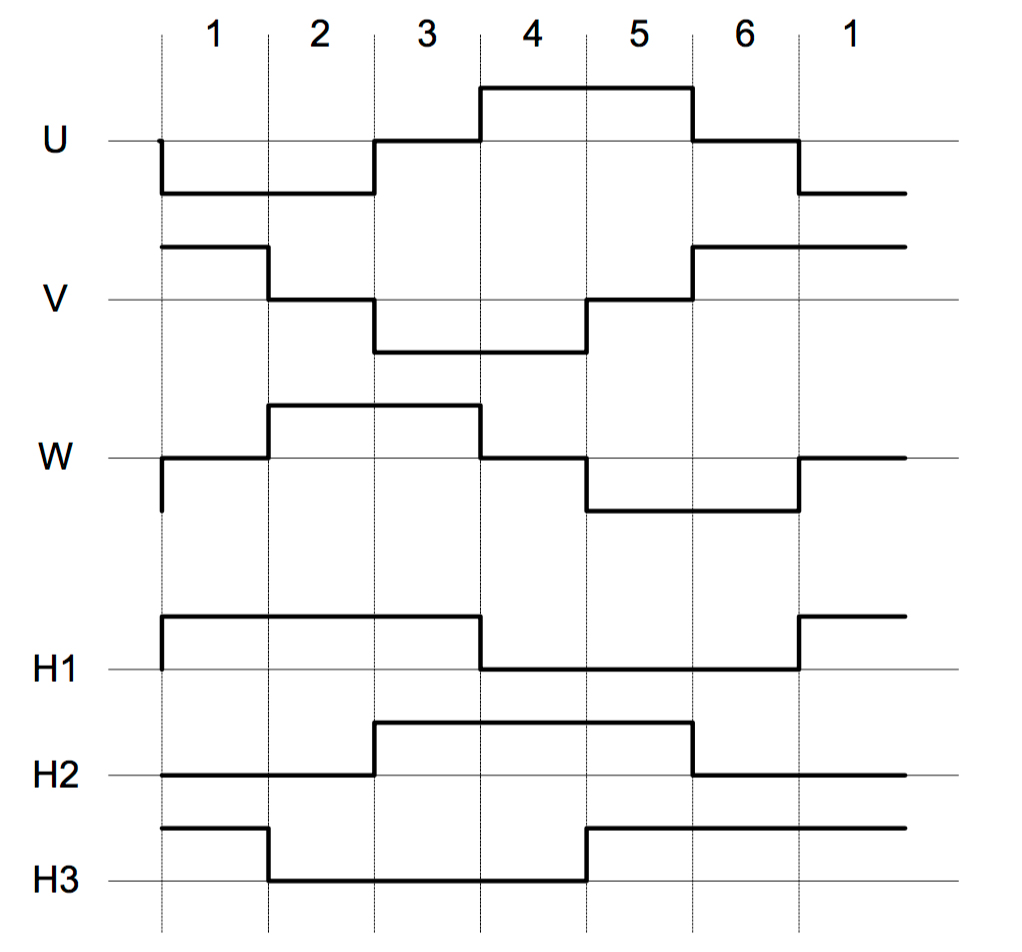

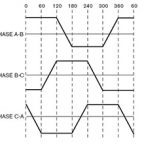

In order to energize the correct stator winding, the rotor position must be known. This is the job of the Hall effect sensors—to monitor the rotor’s position. BLDC motors typically have three Hall effect sensors mounted either to the stator or to the rotor, and use what is known as six-step commutation. When the rotor passes a sensor, it produces either a high or a low signal to indicate which rotor pole (N or S) has passed. This switching of the three hall effect sensors (from high to low or from low to high) provides rotor position information every 60 degrees.

Image credit: Atmel Corp.

60° multiplied by six steps equals 360° or one full rotation. Hence, the term six-step commutation.

Hall effect sensors are the most common method of determining rotor position in BLDC motors, due to their low cost and ease of use with the permanent magnets of the rotor. And since the commutation happens in 60 degree increments, high-resolution sensing and output are unnecessary.

For a comprehensive but easy-to-follow tutorial on six-step commutation, check out this video from maxon motor.

Leave a Reply

You must be logged in to post a comment.