When voltage is applied to a piezo ceramic material, the material experiences a displacement (expansion or contraction) per the inverse piezoelectric effect. The amount of displacement that results from the applied voltage depends on thickness of material. Thus, for a given displacement, a thinner material requires a smaller voltage than a thicker material. Low voltage piezo actuators are generally classified as those that operate below 200 V.

The inverse piezoelectric effect refers to the strain that is induced on a piezo material when it is subjected to an electric field (V/m).

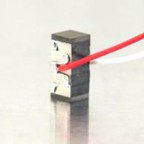

Image credit: Physik Instrumente

Low voltage piezo actuators are typically based on a multilayer, or stacked, design, in which very thin layers of piezo ceramic material are electrically connected in parallel. The multilayer design exploits the benefit of smaller thickness to reduce the required voltage, while the parallel connection scheme maximizes the total displacement.

How it works

A low voltage actuator uses layers that are just 50 to 200 microns thick each, sintered together. Because the required operating voltage is based on the thickness of each layer, rather than on the total length of the actuator, the required voltage is kept low. However, the total displacement of the actuator is the sum of each layer’s individual displacement. The result is an actuator that operates at a low voltage but produces a large displacement.

When operating well below its resonant frequency, a piezo actuator behaves like a capacitor, and its displacement is proportional to the stored electrical charge. Capacitance is proportional to the cross-sectional area of the actuator (perpendicular to the direction of the electric field) and inversely proportional to the thickness of each layer.

![]()

Where:

C = capacitance (F)

n = number of layers

ε = dielectric constant (As/Vm)

A = cross-sectional area of the actuator (m2)

T = thickness of each layer (m)

Note that the capacitance of piezo ceramics varies with the amplitude of the voltage, the temperature, and the mechanical load. Be sure to check the conditions (voltage, frequency, and temperature) that were used by the manufacturer to determine the published capacitance values.

Low-voltage piezo actuators are used in applications where the required force is in the range of several dozen kilograms (as opposed to several thousand kilograms with high voltage actuators), such as nanopositioning. And because their voltage requirement is very low, they are also well-suited for applications where power is supplied by a battery, such as consumer electronics equipment.

Feature image credit: Physik Instrumente

Leave a Reply

You must be logged in to post a comment.