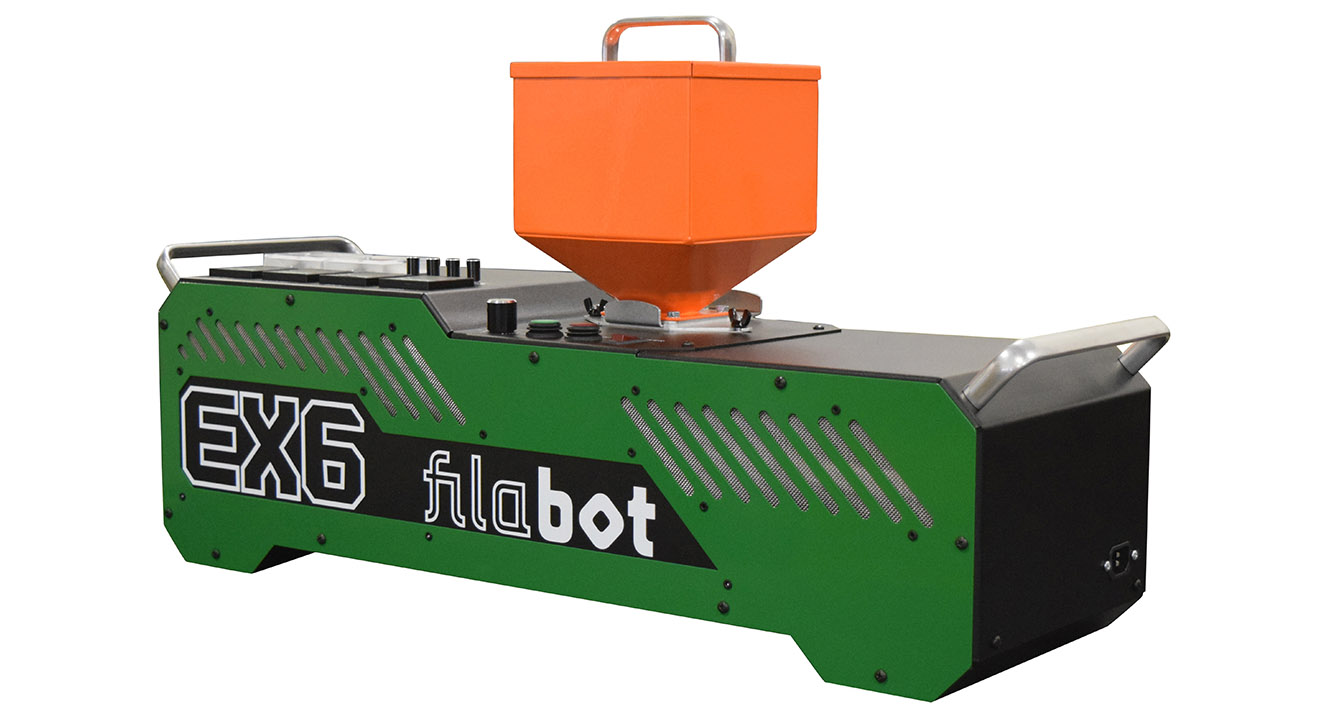

Filabot, a manufacturer of plastic-extrusion machines for the 3D printing market, has just released its new and improved EX6 filament extrusion machine.

The Filabot EX6 improves overall extrusion process control and consistency compared to previous models, by adding features which are standard on industrial-scale extruders. The EX6 has a higher output compared to other systems of this size, but is efficient enough to run off a 15-A 120-V outlet. Filabot also focused on versatility for the new EX6, which can extrude filaments in an array of different polymer grades and types.

The EX6 has multiple-zone heating and cooling for the barrel and feed throat and an industry-standard 24:1 length-to-diameter screw ratio. A motor upgrade allowed Filabot to use a screw that’s longer than those on legacy systems. Therefore, boosting material output. So, why is that important? In single-screw polymer extrusion, a longer screw improves output pressure and material consistency. It also allows for more room in the machine to accommodate multiple screw geometries that Filabot offers to improve the output performance of specific polymers.

In fact, the main design improvement that differentiates the EX6 from other offerings is its longer screw — a screw that necessitates a compact but powerful and consistent drive system. For this portion of the design, Filabot turned to Klauber Machine & Gear, a fractional horsepower gearmotor manufacturer based in Missouri.

Klauber engineers assisted the team at Filabot by executing performance tests on prototype drive motors and then helped Filabot choose a gearmotor with suitable output power.

“The array of gearbox and motor configurations from Klauber made the motor we chose easy to integrate and decreased the complexity of the overall system design,” said Filabot CEO Tyler McNaney.

Klauber is part of Trident Motion, a new group in the motion-engineering industry. Another company of Trident, American Control Electronics (ACE) also supplies motion components to Filabot for the EX6.

“PWM drive options from ACE also made it easy to choose a small, simple to integrate drive with the options we needed … including potentiometer speed control and IR compensation,” added McNaney.

The high-quality output of the ACE drive runs the motor cooler and more efficiently than other drives Filabot tested, which Filabot engineers say will improve the durability and expected life of the EX6.

For more information, visit the websites of the manufacturers and machine builder in this story: Filabot • filabot.com | Klauber Machine & Gear • www.klaubergear.com | American Control Electronics • americancontrolelectronics.com

Leave a Reply

You must be logged in to post a comment.