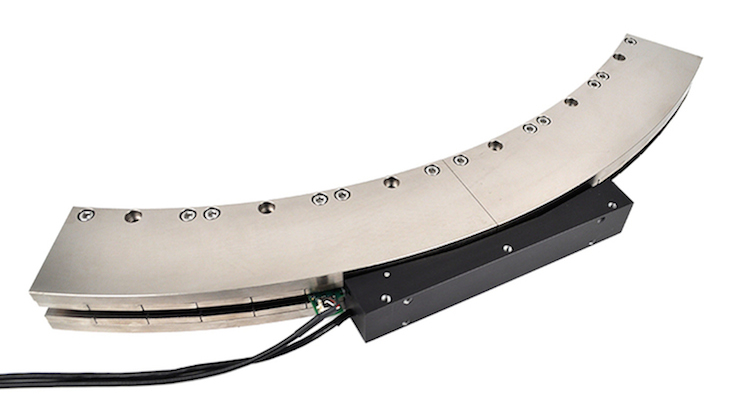

H2W has developed an un-housed arc segmented frameless brushless torque motor with low inertia moving coil assembly for high angular acceleration applications. The TWR-070-410-1150-3PH, a rotary 3-phase brushless motor, also known as a rotary servo motor, is a direct drive motor that is suitable for limited or unlimited, closed loop servo, rotary motion applications. It can generate a continuous/peak torque of 480 in.-lb (53 Nm)/ 1,440 in.-lb (159 Nm). It has been designed to have a 70° rotation and operate on a 20-in. (500 mm) radius, but additional modular magnet tracks (33° each) can be added to increase angular displacement. It’s capable of precise position, velocity, and acceleration control when coupled with a rotary encoder for position feedback.

The vacuum encapsulated moving motor coil assembly moves through a gap in the long U-shaped magnet assembly. A customer supplied bearing system is required to guide the moving coil assembly and to maintain a .050-in. (1.25 mm) clearance between the magnet and the coil assembly. There is no attractive force between the motor coil and the magnet assembly. The 3-phase motor coil assembly can be commutated trapezoidally using integral Hall effects or commutated sinusoidally using software commutation in conjunction with the appropriate amplifier, motion controller and encoder feedback. The power to the motor, from a brushless servo amplifier, is supplied via a high-flex motor power cable. Motors can be designed to fit customer-specific application requirements.

Features include:

- Zero cogging

- High speed and accelerations of light loads

- Low inertia

- Multiple motors coils inside a single magnet assembly

- Uses standard 3-phase brushless amplifier

For more information, visit www.h2wtech.com.

Leave a Reply

You must be logged in to post a comment.