Heason Technology has recently released a new 20-page catalogue that features Nanomotion’s ceramic servo motors, as well as piezo sub-systems and drives. In particular, it showcases the miniature EM1-S-O ‘Edge’ ceramic motor — the tiniest industrial direct-drive motor of its kind.

The EM1-S-O ‘Edge’ ceramic motor can be easily installed into space restricted mechatronics assemblies. It delivers a dynamic stall force of 0.3 N and has a wide velocity range. Apart from that, the motor is capable of operating at speeds up to 250 mm per second in smooth increments of ten nanometers, with zero backlash.

In addition, the EM1-S-O ‘Edge’ ceramic motor can be easily mounted directly into the client’s encoder- and bearing- based closed loop servo feedback system. It also provides a very accurate and exceptionally smooth rotary or linear motion, either in synchronized groups or individually for additional dynamic performance.

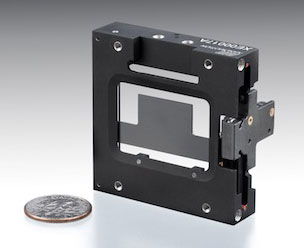

Nanomotion’s EM1-S-O ‘Edge’ ceramic motor is also offered as a packaged sub assembly as shown in the latest catalogue by the S787 NUC (Non Uniformity Correction) Shutter. This is utilized extensively in the field of infrared thermal imaging. However, it may also be used in other photonic applications such as those in industry and research.

Furthermore, the ceramic motor’s miniature leaf shutter is also able to move 15mm in just 100 milliseconds. It is also normally supplied with an ASIC drive that shuts the position loop, and serves as a comprehensive drive and control system.

Heason Technology

www.heason.com

Leave a Reply

You must be logged in to post a comment.