Portescap’s newest surgical motor for large-bone orthopedic powered hand tools is a size 12 (31.5 mm diameter) mini motor available in 9.6-V, 12-V and 14.4-V. With cannulated and non-cannulated options, these motors can deliver peak torques of up to 1,720 mNm in a compact envelope.

These drives are suitable for various applications such as orthopedic drills, reciprocating saws, oscillating saws, sagittal saws and reamers. In addition, size 12 motors can also be used in robotic surgery applications, surgical screwdrivers and exoskeletons.

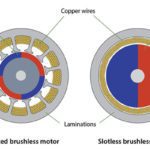

Portescap’s brushless dc slotted miniature motors for surgical power tools are designed and manufactured using a unique process that encapsulates and protects stators windings and electronics from harsh external environments like autoclave and dish wash witnessed by these applications. In addition, Portescap insulates the windings per the medical safety requirements for hi-voltage protection that is mandatory for surgical powered hand tools.

Portescap has been collaborating with surgical power tool manufactures for over 20 years to supply miniature motors custom engineered for critical performance. Upon request, the drive systems can be coupled with autoclavable gearheads with different reduction ratios, autoclavable encoders and autoclavable controllers to meet the application needs. These drives come in different varieties to meet the divergent customer needs of reliability. Portescap motors are manufactured in an ISO/OSHA certified facility, and are RoHS compliant.

Samples are available in less than two weeks to help speed up the crucial design phase when multiple quick iterations are important to finalize the application specs.

For more information, visit www.portescap.com.

Leave a Reply

You must be logged in to post a comment.