by Dan Jones, Director of Engineering Dynetic Systems, Inc. Elk River, Minn.

When off-the-shelf motors can’t meet the specs, you might have to go custom, but it’s not as bad as it used to be.

Pilotless aircraft engine controls and avionics have joined with the “X-box” and miniature motor-control devices and graphics displays to create a new generation aircraft designated the Unmanned Aerial Vehicle or UAV. Aerial vehicle names like the Predator, Reaper, Shadow and Mexican-S4 are currently working in strategically assigned reconnaissance roles.

Designing a custom motor can be an expensive undertaking, and most of us try to avoid doing so. But sometimes cost has to be a secondary consideration, especially when an off-the-shelf unit cannot be made to meet certain tough specifications—such as military standards AS9100. This is roughly the equivalent of the more familiar ISO 9000 industry standards, wherein both documents demand a rigorous control and quality assurance system.

One specific design example is an electric fuel-pump motor developed for an Unmanned Aerial Vehicle (UAV) such as the Predator, Reaper, Shadow and Mexican-S4. No off-the-shelf motor can survive the challenging environment needed for this UAV application, so a custom one had to be designed. What made this small motor-design job particularly tough was meeting the torque requirement over a specific temperature range at an unusually low motor weight. Other hurdles included a tight schedule, the ability to maintain robust communications with a specific pump manufacturer, match the motor to a drive, and engage some prior application experience on the motor maker’s side that was necessary to mate the motor, pump and drive components flawlessly.

The detailed component design requirements are contained in a military working specification, DO 160, which covers numerous electrical, mechanical, and environmental conditions that must be met. For example, the fuel pump itself provides a 40 PSI operating pressure continuously over all environmental conditions, and the brushless PM motor that drives it must operate from sea level to 60,000 ft at ambient temperatures that range from -65°F to +165°F. The goal was to provide a

compact package that meets the rated torque of 25 oz-in. at the rated speed of 7450 rpm and maximize motor efficiency at this operating point. And this is all accomplished with a brushless PM motor and a drive that weighs 3 pounds or less.

The Motor Design

The low weight of the motor pretty much dictated that a high-energy Neodymium-Iron-Boron magnet be selected that could simultaneously handle the specified torque over the temperature range. Such component specs for the Military usually push the design envelope. The major criterion here was to keep the soft iron flux density in the stator below 17 kgauss.

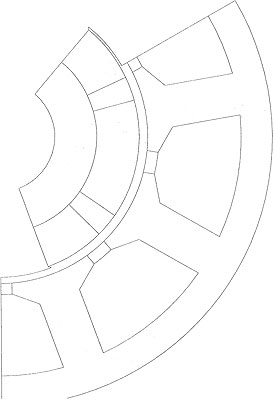

A special stator winding was designed to interface with the Neodymium-magnet rotor. Although this was a custom design job, not enough time was available to produce a totally new stator lamination geometry, so an existing stator was chosen. A “T-segmented” stator lamination was selected to obtain the maximum stator winding slot area for the highest copper volume. The stator winding that can be used with T-lamination teeth is defined as the fractional pitch winding that wraps directly around each lamination. It is the shortest mean length of a copper turn possible which can minimize the phase resistance and develop more than sufficient motor torque.

As with many new applications, the customer increased the rated torque requirements during the program and maintained the original rated speed requirements. This new requirement increased the motor’s output power by 56%, but the motor was able to achieve the new requirements without changing the envelope. The basic motor design and drive characteristics were completed over a 3½ week time period.

The initial mechanical configuration was a short stack size 23 brushless PM motor only 5.8 inches long, which included the drive. The shorter length was needed to meet the tough, low-weight requirement. However, the motor’s outside diameter was expanded to accommodate a rugged explosion proof housing that is necessary for this UAV application. Finally, the mission-critical nature of the UAV required that the fuel pump motor be sealed. The design and prototype build time plus initial motor testing took three months.

This motor is currently undergoing formal acceptance testing and then will move into life testing. Approximately 15 weeks elapsed between the initial project start and prototype delivery.

Using Motor Design Tools

An effective, but comparatively expensive, magnetics design analysis program that was used for this project is called SPEED. It was developed by the University of Glasgow, UK’s research laboratory of the Department of Electronics and Electrical Engineering. It contains numerous levels of design analysis, and on average, it is updated annually with new features to improve its capability and make it easier to use. The specific brushless PM motor design program selected was called PC-BDC. It is extremely fast and provides comprehensive data, but it does not replace the design engineer. PC-BDC only indicated that the nominal operating parameters could be achieved. The next step was to begin evaluating the impact of environmental conditions on the overall motor performance. Thermal characteristics for any motor are the limiting factor for overall operation. The design program, PC-BDC, can be used to evaluate this impact of ambient and motor temperature rise conditions on the motor. A typical procedure using this program is:

• Review requirements

• Select the permanent magnet material for the rotor.

• Select the soft iron for the stator lamination. The SPEED program contains a library of performance data for the magnets and the soft iron materials.

• Match the mechanical parameters as input to the program (size, volume, weight).

• Based on experience or available stator tooling, select the number of rotor poles and stator slots

• Using the program, match the torque and speed requirements with the electrical inputs and change the internal motor geometry as required.

• Select the winding pattern and optimize turns, wire size, and stator winding slot fill.

• Check the program outputs for validity.

• Iterate. Run other solutions varying certain parameters for optimization such as:

1. Add and remove a winding turn

2. Change air gap between rotor and stator

3. Change magnet thickness

4. Check thermal performance and impact on motor operation

5. Verify impact on tolerance, voltage, current, and so forth

6. Check the program’s solutions vs. customer requirements and select the best match

• Re-verify the solution vs. the requirements

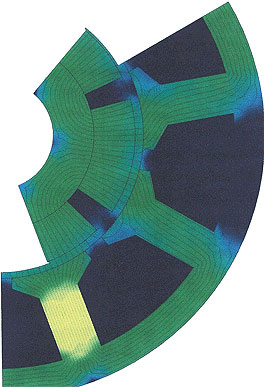

The output of the SPEED program gives designers a clear view of the flux paths and geometry of the stator and rotor of a well-designed motor—which was achieved only after a series of iterations. The goal here was to keep the soft iron flux density in the stator below 17 kgauss.

In addition to SPEED, SolidWorks was used as the mechanical design tool. The 3D model is particularly useful for the pump manufacturer. It can ensure that the motor fits in the selected envelope. It also generates both the motor’s physical assemblies in 3D, and then it pulls out the components in a traditional 2D drawing format. The motor outline and general assembly drawings are made available to the customer for review.

The Drive

The electronic drive type selected for this application is a sensorless-voltage drive. The motor’s back-EMF signal synchronizes motor-phase switching relative to shaft position. This particular drive has already been proven in many variable and fixed speed applications, which gives it a high confidence level for success. Typical speed regulation is 3% over a wide speed range, but the drive also controls the motor accurately at a single speed over a wide range of load conditions.

Additional major operating requirements include soft-start and current-limit features. The drive limits the motor’s starting current to below 38 A. The drive is piggy-backed on to the motor and takes up less than 1.3 inches in axial length. There are a number of advantages to placing the leads on the back of the motors, including short motor-drive connections which significantly reduce RFI noise. And because only two leads exit the brushless PM motor, it looks like a simple brush-dc motor.

Dynetic Systems

www.dynetic.com

SPEED Software

Contact Magsoft Corp.,

Ballston, New York:

www.magsoft-flux.com

Leave a Reply

You must be logged in to post a comment.