Serial peripheral interface (SPI) is a commonly used input-output standard for synchronous data transmission. It transmits data between microcontrollers and peripheral devices such as sensors, memory cards, and displays, among others.

At its most basic physical level, it’s a four-wire serial interface with data rates that can vary from a few MHz to upwards of 10 MHz or better in some cases. Data transmission is from two to 24 bits, depending on how it is programmed.

With regard to how SPI applies to dc motors, the motors themselves aren’t driven directly via SPI but rather by way of a motor driver.

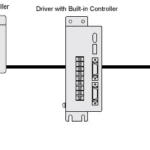

Typically, a motor driver with SPI connectivity will have an SPI port that can be connected to a microcontroller which sends control signals such as PWM signals. Or in some cases the controller may reside on the same chip where the control signals are generated. Aside from control, SPI can also be used for diagnostic purposes.

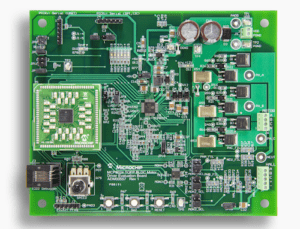

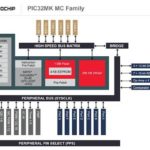

One benefit from a microcontroller programming standpoint is that most microcontroller families have built-in SPI communication, making it easy to connect with peripherals. Another benefit is that programming via SPI is fairly simple. The protocol is fairly easy to understand and support circuitry is not complex … so straightforward to implement.

On the down side, it is generally a short-distance communication link. Some of the largest distances have pushed the 100 m mark. However, with longer runs more signal delay is introduced, which affects timing of signal propagation.

Still, there are many examples of controlling dc motors with simple controller chips using an SPI interface — including the Raspberry Pi, Arduino, and motor drives from Microchip.

One short-distance SPI application on some motion controllers it that of accommodating expansion modules.

| Module header pin |

Signal |

Description |

| B38 | GND | Ground |

| B41 | SPI_CLK | Serial peripheral interface clock |

| B42 | SPI_IRQ | Serial peripheral interface interrupt request |

| B43 | SPI_SOMI | Serial peripheral interface slave output master input |

| B44 | SPI_SIMO | Serial peripheral interface slave input master output |

| B45 | SPI_CS2 | Serial peripheral interface chip select 2 |

| B46 | SPI_CS1 | Serial peripheral interface chip select 1 |

Via SPI connections, some dc motor drives may supply outputs and transmit information on normal motor operation, open-load and overcurrent conditions, as well as temperature alarms.

Leave a Reply

You must be logged in to post a comment.