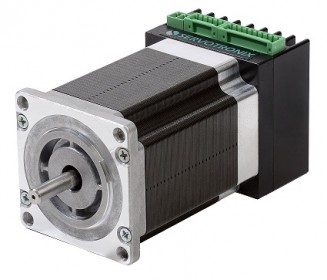

To meet the market’s growing demand for greater machine efficiency and cost reduction, HS Motion Group recently introduced a series of closed-loop integrated stepper motors as an off-the-shelf product. With a superior closed loop control and a cost-effective design, stepIM provides an efficient and affordable solution for applications that require the performance of a servo at the price level of a stepper.

“Many organizations need the exhaustive capabilities of a servo, but cannot afford to make that investment. With stepIM, they’re meeting their application, and budgetary, needs,” said Phil Horner, CEO HS Motion Group.

“Many organizations need the exhaustive capabilities of a servo, but cannot afford to make that investment. With stepIM, they’re meeting their application, and budgetary, needs,” said Phil Horner, CEO HS Motion Group.

The closed loop commutation significantly enhances the performance of the stepper motors, when compared to conventional open loop control. The integrated electronics control the stepper motor as a two phase BLDC motor, implementing position, velocity, and DQ current control loops, as well as advanced control algorithms. With its integrated magnetic 12 bit absolute encoder and an update rate of 16 kHz stepIM ensures accurate positioning and optimal torque utilization at any speed.

stepIM is currently available in several sizes: NEMA 23 in three lengths and NEMA 34 in two lengths. Its operating voltage ranges from 14 to 48 VDC. Depending on motor length, the torque ranges from 1Nm to 7Nm. Furthermore, stepIM offers four digital inputs, two digital outputs and one analog input. stepIM controls the axis via CANopen fieldbus according to CiA 402 protocol, and supports six standard CANopen modes of operation: profile position, profile velocity, torque profile, homing, and cyclic synchronous position.

“stepIM is going to open doors for more than a few select groups – this is going to beneficial for an entire market,” said Horner.”We’re excited to see this line grow, and to explore how its intuitive design and economical value benefit customers in enhancing their operations, and their business.”

The stepIM series significantly reduces cost, space and machine complexity and as such is perfectly suited for decentralized machine architectures. The integrated design of motor, control, and power electronics minimizes the effort and expense associated with machine installation, as wiring and cable routing are reduced. Besides the ease of installation, machine complexity is reduced as fewer components and less electrical cabinet space is required.

For more information, visit hsmotion.com.

Leave a Reply

You must be logged in to post a comment.