Like servo motors, stepper motors are available in both rotary and linear designs. When an application requires force (rather than torque) output and can operate in open loop control, a linear stepper motor is often the preferred solution. Although linear stepper motors are available in both variable reluctance and hybrid designs, the more common version is hybrid linear stepper motors.

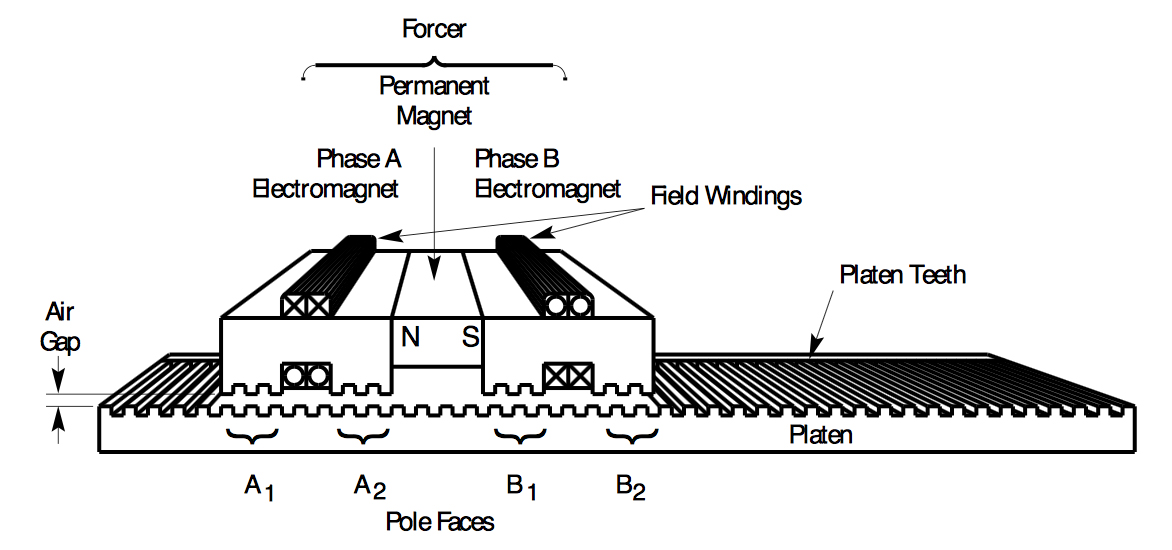

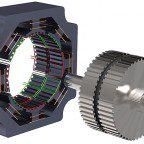

In a hybrid linear stepper motor, the base, or platen, is a passive steel or stainless steel plate with slots milled into it. The forcer contains motor windings, permanent magnets, and laminations with slotted teeth that serve to concentrate the flux that’s created when current is applied to the coils. The teeth of the forcer and the platen are staggered by ¼ tooth pitch in relation to one another to ensure that constant attraction is maintained and that the next set of teeth will come into alignment as current is switched in the coils. This means that for each full step of the motor, the forcer moves along the platen by ¼ tooth pitch.

Image credit: Parker Compumotor

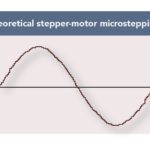

Whereas variable reluctance linear stepper motors can only operate in full step mode, hybrid versions can operate in either full step or microstepping modes. Microstepping, which divides the step angle into smaller increments, enables higher resolution motion and better control of speed and force. Because each phase of the motor is driven with (theoretically) ideal sine waves, 90 degrees apart, microstepping also allows the current to increase in one winding as it decreases in the other, providing smoother operation at low speeds than can be achieved with full- or half-step operation.

Image credit: Servo-drive LLC.

For guiding the load on hybrid linear stepper motors, either mechanical roller bearings or air bearings are typically used. (Because the platen in a hybrid linear stepper motor is passive, it can serve as the air bearing surface.) The magnetic flux between the forcer and platen creates a strong magnetic attraction, so these support bearings actually serve two purposes – to guide and support the load and to maintain the correct air gap between the forcer and the platen.

Like other linear motor designs, hybrid linear stepper motors can incorporate multiple forcers onto one platen, with each forcer moving independently. In addition to smooth low-speed operation (obtained with microstepping control), they are also able to achieve very high speeds and accelerations with high resolution and low to moderate force generation.

With simple mechanical construction and easy setup (no servo tuning required), hybrid linear stepper motors are ideal for applications that can operate in open-loop mode and that require either high speed with low force production or very smooth motion at low speed.

Leave a Reply

You must be logged in to post a comment.