The fundamental transmission of mechanical power hasn’t changed in several hundred years — and that includes industrial gear designs. “Coupled to most rotary electric motors is either a chain-sprocket drive, a belt-pulley drive, or a gear drive,” said Brian Dengel, general manager of KHK USA. “Each has its advantages and disadvantages, but none of them have become obsolete,” he added.

Nevertheless, gear design has seen the recent rise of custom gearing; a trend towards manufacturing for better gearboxes and servogear sets; and industry migration towards helical gearing and other efficient choices.

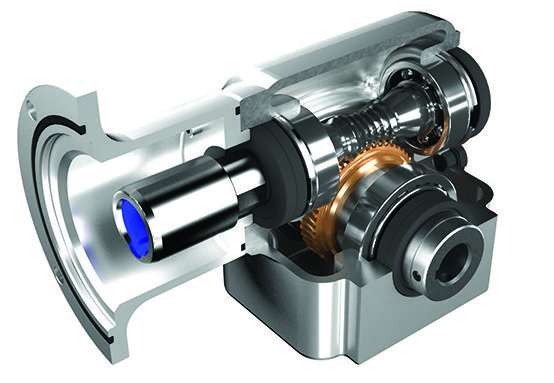

“Many things in power-transmission design for automation have changed over the past decade,” said Marc Halliburton, engineering manager at Motion Index Drives, manufacturer of precision indexing machinery and seventh-axis robot transfer systems. “We’ve seen a huge shift to smaller OEM and end-user designs and applications, which in turn allows use of smaller transmissions and servomotors in automation,” added Halliburton. For electric motors, many engineers specifying indexing machinery are concerned about motor efficiency and want to ensure the ac motors used are more than 90% efficient to conserve electricity. “Here, the power transmissions we use as gear reducers have improved integral designs for space savings as well as efficiency.”

That’s just one example of the move to have motion-component suppliers do more integration and design work to meet user objectives such as efficiency — and one would be hard pressed to find a geared design not touched by the near-universal OEM and plant-engineer demand for upfront engineering to satisfy specific geometries as well. So with more such requests, gear makers have devised ways to simplify gear integration.

Case in point: Around 2000, GAM Enterprises was a cost leader on several motion components, but saw the rise of low-cost overseas manufacturing was going to change that. “So we shifted to offer mass customization, which lets engineers configure end product from a broad range of standard components — a new concept then,” said Craig Van den Avont, president at GAM Enterprises.”In fact, we took the concept a step further to design even custom motion components quickly.”

The company has its origins in the sale of bellows couplings, but is now known for its gear products, which it began making in 1998. Its customized gearboxes came to dominate the expansion into customized products; its latest suite of offerings addresses trouble in another area … that of linear-actuator installation.

“A supplier could get a standard actuator in one or two weeks, but if they needed a motor mount to go on that actuator, especially one that wasn’t part of a standard product line, it could take six or eight weeks,” explained Van den Avont.

“So we replicated what we were doing with gearboxes to offer motor-mount kits. Today, we can take anyone’s actuator, anyone’s motor, and anyone’s gearbox and we can custom-design that mount, machine it, and ship it in a week.” As a testament to how useful that is to industry, today myriad actuator companies source standard and unique motor mounts from GAM.

Others also serve the uptick in demand for semi-standard products. “Traditionally, we supplied a large selection of gears with minimum plain bores and oversized hubs to let end users modify our stock gears,” said Dengel.

“Users could turn the hub down, open the bore, add a keyway, tap threads for set screws, or otherwise modify the stock gear to meet their design requirements. But with significant demand for finished-bore products, we established a line of value-added gears to meet this need. We looked at the most common bore and key sizes for each gear we offer and established a semi-standard product that we call our J series,” said Dengel.

These just-in-time products are made-to-order items with standardized bores and keyways produced within two to three business days from stock gear product — so the specifying engineer doesn’t need to allocate shop time to that, and it goes directly into assembly.

“Many of our system designs are modular, and we sell less costly solutions to complex gearmotor integration — especially if the designer knows upfront what problems were solved in previous iterations and talks to us prior to finishing the design of their new machine or product. After all, why reinvent the wheel?” said Gabriel Venzin, president at Cincinnati-based ABM Drives.

Expanded services are required for such in-house engineering support. “We reorganized our technical sales support to ensure maximum response time of 24 hours to customer or field-sales requests. Plus we expanded our global footprint with a technical center in China. It’s important to have a local presence, speak the language, and understand customers’ culture,” Venzin said.

“We believe to sell proper products to end users, a gear maker must have experienced engineering staff to support end users and confirm the gears they select are suitable for the applications at hand. We let design engineers download 3D CAD models from our website so they can pick what they need and avoid designing something from scratch — a great timesaver. We’re currently working on adding a custom-gear CAD-model generator which will let end users view their design before requesting a quote — which will shorten the time to quote once we review their design,” said Dengel.

Certain industries — including e-mobility, packaging, and offroad equipment — are currently prompting the newest gear design. “Electric vehicles will continue to push the industry with the need for lightweight high-efficiency drives and motors. This applies to human-powered material handling and UTVs as well as autonomous in-plant vehicles and AGVs,” noted Venzin of ABM Drives.

“We find the packaging-equipment industry is the most dynamic regarding custom-product requirements,” said Dengel. “Many machine builders have a standard design but customize every packaging line to their customers’ specifications. This results in a custom setup in almost every case. Although some of the components are interchangeable, design differences can require custom product for each machine.”

One specific application showcases where engineers use myriad gear components to improve a given design. “Nobody likes noisy heating and cooling systems, and that goes for biomass systems incorporating auger drives. Over the last ten years, ABM Drives has combined many technologies to make super-quiet and highly efficient drives — including aluminum cases and helical, beveled, self-centering gears. There’s a reason you don’t make bells out of aluminum,” noted Venzin.

Hot topics: 3D printing no — new materials, yes

Gear design shows mixed adoption of new manufacturing options and tools. “Industry 4.0 has already increased connectivity demands for manufacturing and conveying lines, as well as the monitoring of individual critical gearmotors. In contrast, 3D printing allows much quicker prototyping, but because most gearbox and motor components are produced in high volumes, I don’t see 3D to be competitive now,” Venzin said.

“Regarding additive manufacturing and 3D printing, these technologies are great for prototyping for fit, feel, and proof of concept, but they’ve not yet advanced to the speed of traditional manufacturing,” agreed Dengel. “As such, they’re useful in gear R&D but not production. We’ve had customers tell us that they can produce a gear in four hours; we produce 100 of the same gear in one hour. The efficiency is not there yet.”

New materials are on the horizon, though. “We see carbon fiber making large inroads in automotive, and there’s no reason that better and lower-cost processing won’t prompt the introduction of composite gearing. Weight is always a concern, and any technology that helps reduce it will be quickly embraced when the economics make sense,” Venzin said.

Again, other industry experts agree with Venzin.

At the recent MD&M West in Anaheim, Calif., KHK displayed prototype gears it’s made from carbon-fiber-reinforced plastic (CFRP), a material increasingly common in sports equipment and performance vehicles and yachts. (The KHK samples are of PA6/CF20% thermoplastic from Toray Plastic Precision.) So CFRP may soon offer another advanced gear option for aerospace, drone, and automotive applications. CFRP gears are costly but extremely light and (in many cases) many times stronger than steel.

Leave a Reply

You must be logged in to post a comment.