As the Internet of Things becomes reality, manufacturers are responding with products to aide designers of next-generation motion systems.

The Internet of Things. A lot has been written about its promise, its potential to revolutionize just about everything we do, from giving us talkative toasters and smart refrigerators to uber-connected factories. There’s even a counterpart in the industrial world; the so-called industrial Internet of Things (or IIoT).

The dream, of course, is to connect everything from the lowliest bearing or sensor on a machine on the factory floor all the way up to the enterprise resource planning (ERP) system, to have one interconnected whole. And companies are beginning to put the pieces together.

One important factor impacting the growing availability of IoT offerings is cost. Much of the technology is no longer cost-prohibitive, leading designers to network-enable practically anything with low-cost sensor technology, unlocking and storing data that was previously unavailable.

A brief survey of some of the latest releases for IoT applications in motion systems shows a range of offerings, from hardware devices to software tools, such as development environments and networking apps that help connect devices, components and systems together.

IoT-enabled controllers

For designers looking to build IoT-enabled motion systems, a growing number of manufacturers offer ready-made solutions. For example, Omron offers their new NX1P Machine Automation Controllers which are at the heart of the company’s Sysmac automation platform. The Sysmac platform brings integration and intelligence to production operations by creating a variety of application functions with software. The new solutions improve production processes by leveraging expertise in advanced fine-tuning control gained through the NJ/NX Series used for state-of-the-art large-scale equipment and next-generation equipment.

The NX1P provides both advanced motion control and a network environment for IoT at production sites, applying know-how in advanced fine-tuning control to small and middle-size machines. This offers equipment manufacturers the ability to add advanced, smart functionalities to small and middle-size production machines as well as state-of-the-art production equipment to increase processing speed and accuracy and to use production data for predictive maintenance.

The NX1P comes with a built-in EtherCAT port and controls up to eight servo systems, and offers motion control for up to four synchronized axes. It also features electronic cam functions for continuous and high-speed machine operation and interpolation for precise machining, improving productivity and manufacturing quality.

The controller offers extensive IoT capabilities. Data can be collected from devices via EtherCAT and IO-Link for high value-added manufacturing. The NX1P can monitor sensor data through the IO-Link master unit to reduce downtime by detecting errors and to perform predictive maintenance by monitoring status. EtherCAT connects I/O devices, motion devices, vision systems, and safety controllers with a single cable. Machine information can be checked by monitoring the status of the connected components. Meanwhile, EtherNet/IP enables data sharing with a host PC and between controllers on different machines.

The built-in PLC features an LD instruction execution time of 3.3 nsec, the fastest in its class according to the company. The built-in EtherCAT master functionality allows the NX1P CPU to perform high-speed motion control and remote I/O control. Sequence control and motion control are integrated in one controller. The built-in position control functionality reduces not only loss of communication time between the CPU and position control unit but also complexity of communication settings between the units.

The NX1P conforms to the IEC 61131-3 standard programming and PLCopen (R) Function Blocks for motion control. And programming with variables allows users to create complex programs efficiently.

Built-in sensors make smarter motors

At the level of individual components, companies are adding built-in IoT capabilities. For instance, earlier this year ABB/Baldor announced their new Smart Sensor which integrates into the company’s motors and is used to collect and analyze data on operating conditions.

As Michael Offik PE and Director of Packaged Solutions with ABB/Baldor Electric Company explains, “the Smart Sensor actually consists of several sensors and micro-processing capability. The Smart Sensor measures temperature, vibration and a few other key parameters to determine the motor’s overall condition. ABB’s decades of experience with induction motors have allowed us to develop proprietary algorithms that translate these measurements into the health condition of the motor.”

The Smart Sensor attaches to the motor mechanically and on newer Baldor motors it will simply be attached with two screws. For retrofits of existing motors, it’s attached to a mounting bracket with screws. Ideally, the sensor is placed on the side of the motor toward the drive end with the long axis in the motor’s axial direction.

Primary applications for the Smart Sensor are any low-voltage industrial motors where users want to increase motor uptime, efficiency and operating life. (ABB/Baldor considers motors of 690 Vac and below to be low voltage.)

The Smart Sensor communicates to a smart phone via Bluetooth Low Energy. From here, it’s transmitted to the cloud for some additional processing and then the overall condition is sent back to the phone and displayed via a user-friendly app. The smart sensor is a monitoring device only and does not control the action of the motor. In addition, ABB states that it uses the latest security measures to ensure information is safe and secure, a chief concern for many IoT applications.

Software tools for IoT development

On the flip side, there are vast legacy systems of sensors, motors, machines, and other devices that already are a part of the existing industrial infrastructure but are currently unable to connect to the IIoT. This legacy equipment holds valuable untapped data needed to improve business processes and decisions in almost every enterprise and every industry.

“The Industrial Internet of Things is built on the idea of seamlessly sharing data between disparate assets to identify new opportunities for businesses to become more competitive,” notes Matt Newton, Director of Technical Marketing for Opto 22.

According to Newton, a communication disconnect between the physical world and the digital world is slowing the adoption and rollout of the IIoT. To cope with this disconnect, current Industrial Internet of Things applications involve layers of gateways and middleware to translate between the physical and digital worlds, making it difficult to realize full benefits of IIoT. This is what Opto 22 has been working on, namely to flatten IIoT architecture by bridging the communication gap with open standards-based Internet tools and technologies. Opto 22’s platform enables developers to rapidly design, prototype, and deploy applications to connect existing assets to the IIoT and share their data, capabilities, and resources with other connected systems and assets.

The company’s new RESTful (Representational State Transfer) API has been added to its industrial programmable automation controllers (PACs), significantly closing the IT/OT gap and promising faster Industrial Internet of Things application development, reduced time to market in machine and system design, and faster automation and control project deployment. In effect, they’ve added a secure RESTful server and open, documented API to a programmable automation controller (PAC). The REST architecture and technology are intrinsic to the Internet of Things and paramount to web and mobile-based application development.

Developers can gain secure programmatic access to new or legacy physical assets through control variables and I/O data using any programming language that supports JavaScript Object Notation (JSON). Available through a free updated firmware release for Opto 22 SNAP PAC programmable automation controllers (PACs), the RESTful API includes an HTTP/S server accessible from any HTTP/S-compatible client.

Wireless microcontrollers for IoT

At the electronic hardware level, companies like Texas Instruments (TI) are making available new microcontrollers (MCU) specifically designed for IoT applications.

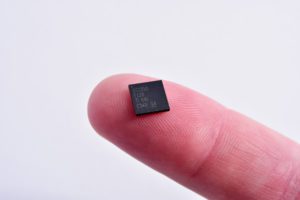

The company’s new CC1350 wireless MCU aims to expand the functionality of IoT networks. The MCU is said to be the industry’s lowest-power dual-band wireless MCU supporting Sub-1 GHz and Bluetooth® low energy connectivity on a single chip. As part of TI’s pin-to-pin and software compatible SimpleLink™ ultra-low power platform, the new SimpleLink dual-band CC1350 wireless MCU enables developers to move from a three-chip solution to a tiny single chip, while reducing design complexity, saving power, cost and board space. The CC1350 offers a range of up to 20 km on a coin cell battery for wireless sensor network applications as well as building and factory automation, alarm and security, smart grid, and asset tracking.

Designed for low-power wide area networks (LPWAN), the CC1350 wireless MCU features a number of helpful features. For starters, the dual-band connectivity expands the functionality of a sub-1 GHz network with Bluetooth low energy implementations such as beaconing, over-the-air updates, smart commissioning, and remote displays among others. This is combined with long-range connectivity paired with ultra-low power consumption that offers a sleep current of 0.7 uA which allows for more than 10 years of battery life. The CC1350 combines an ARM® Cortex®-M3 core in a single, Flash-based, 4×4 mm QFN package.

Developers can get started designing a system with the low-cost SimpleLink CC1350 wireless MCU LaunchPad™ development kit or connect sensors to the cloud with the SimpleLink CC1350 SensorTag demo kit supported by TI’s Code Composer Studio™ integrated development environment (IDE) and IAR Embedded WorkBench®. TI has also simplified development by providing multiple software options including point-to-point communication examples so that developers can use the small, sensor-based kit which includes 10 low-power MEMS sensors and can connect to the cloud in less than three minutes.

Opto 22

www.opto22.com

ABB/Baldor Electric Company

www.baldor.com

Omron

www.omron.com

Texas Instruments (TI)

www.ti.com

Leave a Reply

You must be logged in to post a comment.