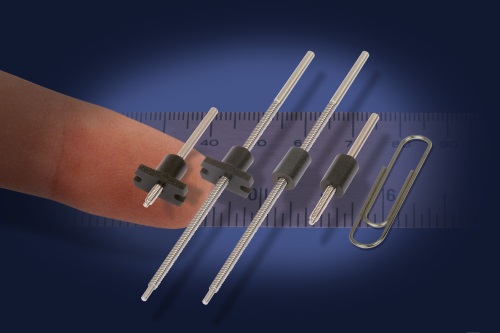

Leadscrews are a staple of motion designs, driving axes on machines big and small. They usually sport higher ratings than comparable ballscrews thanks to more contact between the nut and screw load surfaces. Now, innovations in materials and helix geometry address old issues associated with leadscrew friction, bringing it down to better than 0.10 in some cases—good for fast and dynamic applications. In fact, there’s also been an uptick in leadscrew use because of proliferating machines for 3D printing, manufacturing and medical applications that didn’t exist 10 years ago.

“We’ve seen advances in technology at the component and system level,” said Mark Huebner, market development manager at PBC Linear. “For example, constant-force anti-backlash nuts and leadscrews have given us two to four times better accuracy control while extending useable life by as much as fivefold. We’re also seeing more use of our self-lubricating linear bearings in sanitary and washdown applications, where they resist corrosion.”

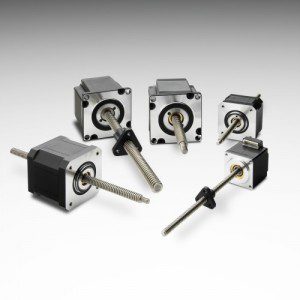

In systems innovations, PBC Linear sees engineers and designers leveraging the advantages of complete packages—pre-engineered alignment built into integrated linear-rail-raceway combinations, for example. “This eliminates the tedious and expensive task of installing and aligning individual shafts or rails while also cutting down the number of components and associated costs,” said Huebner. The same principle applies to integrated stepper-motor-and-leadscrew designs, which eliminate the coupler, mounting bracket, and more for rigidity and accuracy with fewer components, Huebner added. The trend of integrating smart motors also continues—so users can connect to myriad networks while simplifying installation and wire-and-cable management.

Trends in new leadscrew uses

Industries across the board are adopting new leadscrew components and linear systems, but some are leading the charge. Designers of kiosk and automated retail applications are always looking for ways to simplify machines, reduce design weight and simplify assembly and maintenance, according to Huebner. That is where designs with pre-engineered alignment and integrated rails excel.

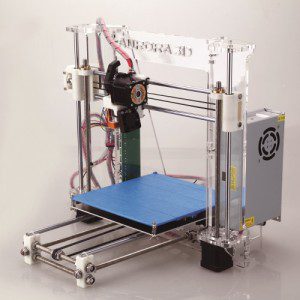

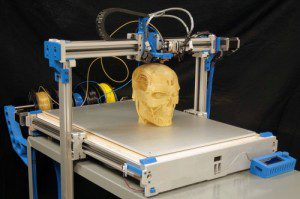

In a similar way, both additive manufacturing (3D printing) and traditional subtractive processes—plasma cutter, laser and waterjet manufacturing—are driving new leadscrew uses. The same holds true for factory automation. “The move to integrated systems, especially those with smart

motors, is giving machines higher control and accuracy, so builders can bring better products to market,” said Huebner.

He added that as 3D printing has become popular in the last 10 years, engineers have wanted to print larger and larger parts … but the linear motion required to do so accurately has been cost prohibitive. “To address this issue, 3D-printer builder 3DP Unlimited has taken our leadscrew-based actuators and integrated linear-motion platform and integrated them into a large-format 3D printer just under $20,000. The build platform is 1 x 1 x 0.5 meters and would not have been possible 10 years ago at such a low price point,” said Huebner. It leverages pre-engineered rail alignment, constant-force anti-backlash leadscrews, and motors with outboard amplifiers that simplify wiring and boost heat dissipation.

Another trend is that more OEM designers and end users are looking to buy pre-engineered linear slides and guides. Several things are behind this trend. “We see this fit with our design on a diet philosophy—the idea that newer

components, integrated design elements and features, and complete solutions bring lower installed cost, enhanced performance, and faster time to market for engineers freed to focus on their core competency and process development,” PBC Linear’s Huebner said.

Leave a Reply

You must be logged in to post a comment.