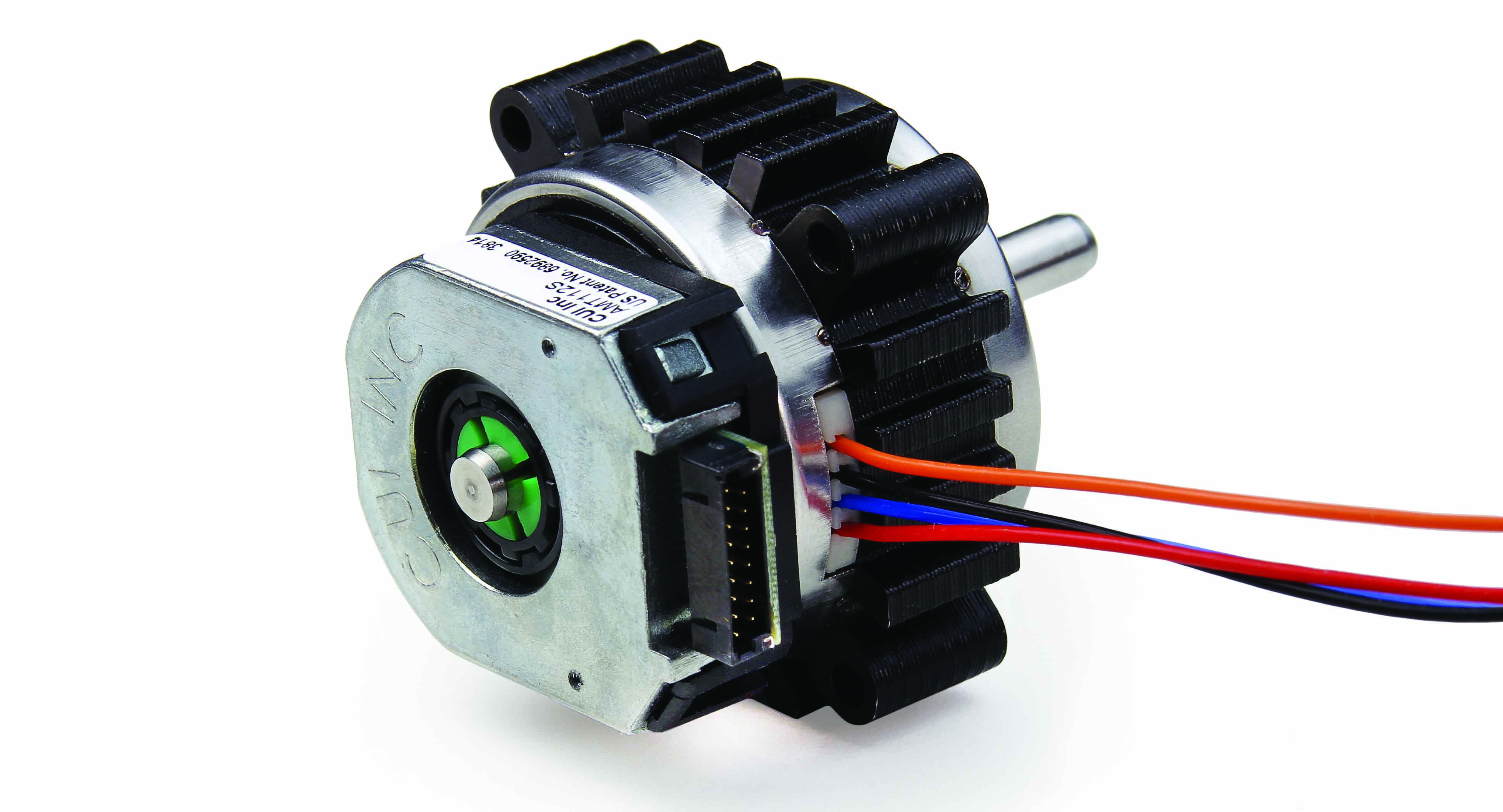

CUI Inc. today announced a partnership with Lin Engineering, a leading manufacturer of stepper motors, to integrate CUI’s innovative AMT encoder technology with Lin’s latest, high performance motor series …

… for a stepper-motor and encoder combo.

Lin Engineering’s G3718V series is a NEMA 17 sized motor with a length of 0.90 inches (22.86 mm) that can produce up to 50% more torque than motors of a similar size. Thanks to its design, the G3718V also features improved passive cooling, increasing overall efficiency and lowering operating costs. More after the jump.

With a step angle of 1.8° the G3718V offers smooth motion and high accuracy similar to a 0.9° motor. The series also provides up to 25 oz-in (0.18 N-m) of holding torque. Various shaft options are available and windings can be customized to ensure maximum torque at desired operating speeds.

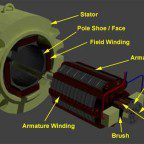

Integrating with Lin Engineering’s top-of-line stepper motor will be CUI’s innovative AMT encoder technology. CUI’s AMT series is a range of rugged, high accuracy modular encoders available in incremental, absolute and commutation versions. Thanks to its innovative design, the AMT series is not susceptible to contaminants such as dirt, dust and oil that typically plague encoders in industrial environments. View details on the G3718V motor series.

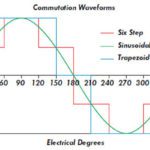

Due to the digital nature of the encoder design, the AMT series also comes with a number of programmable features, including resolutions up to 4096 PPR, zero position, line drivers, and in the case of the absolute version, a 12-bit absolute output. Combined with an operating temperature from -40 up to +125°C, high accuracy, simple assembly and low current draw, the AMT provides a compelling solution for a range of applications.

“Lin Engineering is excited to partner with a well-respected company like CUI. The adoption of their AMT encoder technology with our latest stepper motor provides a uniquely rugged and efficient all-in-one solution unrivaled in the industry,” stated Mindy Cheng, R&D Manager at Lin Engineering.

“The high performance and reliability of Lin Engineering’s stepper motor paired with our innovative AMT encoders presented a tremendous opportunity for both companies,” said Jeff Smoot, CUI’s VP of Motion Control and Application Engineering. “This partnership is the culmination of those efforts to provide a motor and motion control solution in one package and we are thrilled to work with Lin Engineering moving forward,” Smoot concluded. Learn more about CUI’s AMT encoder technology.

Lin Engineering is a step motor, and motion component manufacturer based in Morgan Hill, California. Founded by Ted T. Lin in 1987, Lin Engineering began as a consulting company specializing in step motor applications. Throughout its history, Lin Engineering has continued to develop its capabilities in the areas of design engineering, manufacturing and customer service. In 1991, Lin Engineering expanded its operations to include the manufacturing of its own hybrid step motors. Since then, the company has developed its product line to include drivers, optical encoders, spur and planetary gearboxes, and step motor drives. Today, Lin Engineering serves customers throughout the world with their leading technology designs, high quality products, unsurpassed customer service and unrivaled technical support.

CUI Inc is a technology company focused on the development and distribution of electronic components. At the leading edge of power supply design, the organization supports customers as they strive to improve the energy efficiency and environmental credentials of their application. The company’s power group is complemented by a portfolio of world-class board level components, consisting of interconnect, sound, motion control and thermal products. An unwavering commitment to create collaborative partnerships with customers and a drive to see that their design project is a success has been a hallmark of CUI’s sustained growth since its founding in 1989. As a leader in the industry, CUI will continue to invest in the future through new technologies, talented employees, expanded manufacturing capabilities, and a growing global reach.

Leave a Reply

You must be logged in to post a comment.