Aston, Penn. – For automatic cleaning and lubrication of the drive shaft, Uhing linear drives are now available with a combination shaft scraper/grease fitting option. The addition removes excessive grease, dust and dirt from the shaft while the drive is running and simultaneously assures adequate shaft lubrication.

As debris accumulates at either end of the shaft it can be wiped away with a cloth. In most applications the shaft scrapers may be used without the grease fittings to clean the shaft while the drive runs. The grease fitting combination is recommended, however, in heavy usage applications and also when shaft RPMs exceed rated speeds (1,000 RPM for Model RG drives; 1,500 RPM for Model RS drives).

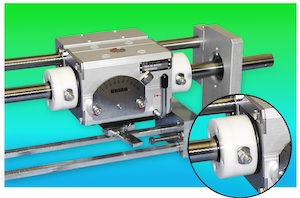

The shaft scraper is an O-ring made of specially formulated rubber which is mounted in a Delrin® brand plastic fitting. One shaft scraper is attached to each of the end bushings on the drive unit. When equipped with the grease fitting, the plastic fitting is made larger to accommodate the addition of a felt wiper ring which wicks oil out of the grease and applies a thin oil film to the shaft as the drive runs. Most standard grease gun nozzles fit the Uhing grease fittings. Note that special, molybdenum disulfide-free grease must be used. If attached in the field, users must also note that the addition of the shaft scraper with or without the grease fitting will slightly reduce the travel distance of the linear drive, which for most applications this is less than 1 in.

Amacoil-Uhing RG linear drives are used in equipment requiring a reciprocating or positioning linear motion component such as material handling systems, winding machines, spraying assemblies, converting equipment and metrology systems.

For more information, email amacoil@amacoil.com or visit www.amacoil.com.

Leave a Reply

You must be logged in to post a comment.