Electromagnetic interference (EMI) and radio-frequency interference (RFI) from ground loops and the operation of electric motor drives can degrade the performance of metal-detection equipment so essential to safe food processing. Here we look at ways to mitigate such issues.

By Eric Garr • Regional Sales Manager | Fortress Technology

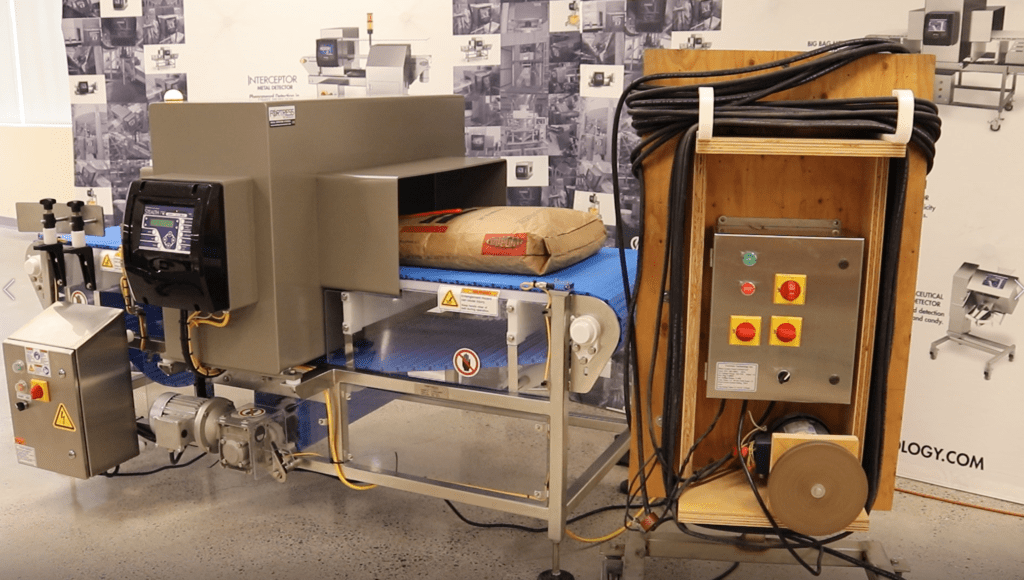

Metal detectors in the food-processing industry are commonly found on conveyor lines to ensure the safety of consumers and protect downstream processing and packaging equipment in the facility. Here, metal detectors help lines reject contaminated product or even sound an alarm and halt operations when steel, aluminum, or other metal particles (either originating from raw food ingredients or worn mechanical elements on processing equipment) are sensed in a given food sample.

The most common metal-detector design in the food and beverage industry is based on a transmitter-receiver coil arrangement in which the former coil continuously emits an electromagnetic field. Should metal contaminants travel through the detector (typically in food riding on a conveyor belt) the receiver coils immediately sense the resulting electromagnetic field disturbance. That in turn prompts an alarm and other machine actions … most typically the removal of suspect food items off the main conveyor line.

Design elements largely determine the performance of a food metal detector. These include the metal detector’s aperture size, product effect, and operating frequency. However, environmental conditions including electrical interference in the form of static, radio, or earth ground loops as well as vibration (as that associated with moving metal) may also affect performance.

In settings where food products are being processed, main sources of electromagnetic interference and radio frequency interference include:

• Motor drives for ac motors — including variable frequency drives (VFDs)

• Drives for servo motors

• Two-way radios (including walkie talkies)

• Electrical loops, electrical contacts, and static discharges

Identifying EMI noise in food-processing settings

The biggest challenges to metal-detector applications in food processing plants are EMI and RFI. That’s especially true for end-to-end lines incorporating food conveyors, pick-and-place or pack robots, bagging, and flow wrapping. The effects of EMI from these motor-driven systems can negatively impact the performance of metal detectors — resulting in false detections, false rejections, and unacceptably low food safety.

EMI and RFI noise occur when different electrically powered machines and peripheral equipment operating near each other are improperly shielded or filtered. Interference most commonly originates from ac motor drives on the conveyor. More specifically, the cables that power the ac motor drive will radiate EMI if shielded incorrectly.

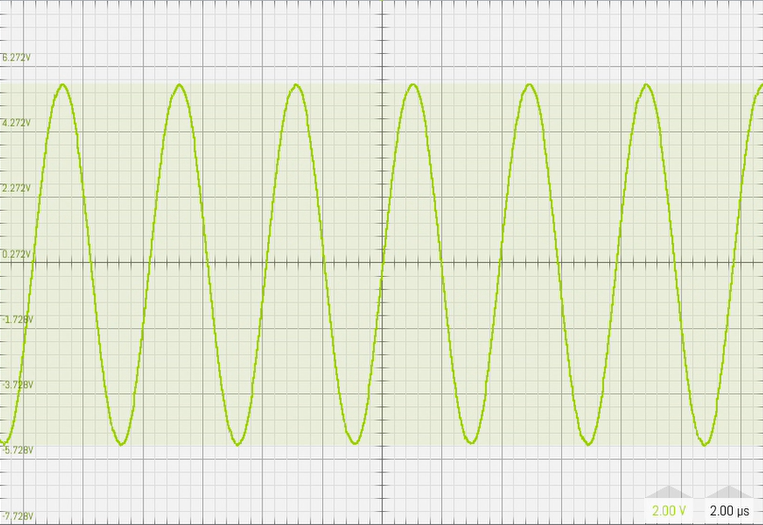

Recall from motion design fundamentals that ac drives work on the principle of switching line voltage to run a motor. This switching causes a fluctuating current draw on the line which in turn causes a broadcasting of RFI and EMI noise back on the ac motor drive input line. A filter can attenuate the draw to eliminate the noise. However, even when this filtering is applied, the output cable to the motor can still radiate noise. Therefore, cabling specifically designed and rated for variable frequency drives should be used on VFDs — to ensure that noise doesn’t broadcast from the cable.

The closer the source of the EMI gets to the metal detector coils, the greater the strength of the signal broadcast. The worst-case scenario is when there’s a clear line of sight from whatever is generating EMI to the metal detector’s opening. If the EMI source is off to one side, the metal detector’s body helps to shield the internal coils from the broadcast noise.

Radio wave issues when detectors are too close together

The susceptibility of a metal detector to EMI is very dependent on its sensitivity and operating frequency. If one metal detector is transmitting at a frequency very close to another and the two machines are positioned close together, they risk electromagnetic cross talking.

To prevent this happening, metal-detector suppliers typically recommend spacing metal detectors at least four meters apart or staggering the metal detectors so they aren’t directly aligned. As part of a site audit, it’s also good practice to note the operating frequencies of metal detectors in proximity so that a different frequency can be selected for any new equipment.

What doesn’t cause issue: Long and medium-wave transmitters such as walkie talkies rarely cause problems with metal detectors — provided that they are operating at 3 W or less and not used in proximity to any metal-detector receiver coils. In addition, mobile communication devices such as smart phones are never a problem for metal detectors. This is because these digital devices’ functions operate at high frequencies — well above the bands used for metal detection.

Common motion-design static electricity sources

Packaging machines including paper and plastic film rollers as well as conveyor belts can create a certain amount of electrostatic interference. However, such interference is rare — and mostly found on operations involving plastic and paper webs that run very close to the metal detector’s coils. This is usually only an issue when the slider beds and conveyor belt material through the metal detector rub enough to cause static buildup that eventually discharges to the metal detector case near its coils. Electrostatic interference can also occur when slider and belt material are incorrectly selected — causing static to build in the metal detector aperture.

Static electricity build-up is more likely to occur on gravity and vertical metal detection applications if the pipework has not been earthed correctly.

Finding and addressing EMI and RFI sources

It’s key to identify the source of electrostatic interference problems quickly and accurately, as ongoing interference on automated processing lines can cause service disruptions. Some metal-detector suppliers can deploy a technician armed with a so-called sniffer to swiftly track the source of EMI and RFI. Like an antenna, such sniffers measure RF and can swiftly locate the source of frequencies competing with metal-detector operations. With this information, engineers can effectively shield, suppress, or alter the emissions path.

Some metal-detector suppliers also offer the option to retrofit existing metal detectors with newer hardware equipped with better noise immunity features. For busy production settings (including highly automated food and beverage plants) this solution overcomes or greatly reduces the effect of the noise on metal detectors.

It’s impossible to eliminate noise interference in food production environments. Yet, by taking precautions and seeking expert guidance, engineers can significantly reduce EMI feedback and protect the performance of metal-detection systems.

User-friendly metal-detector features such as automated single-pass calibration can deliver an accurate system setup within seconds … and eliminate human errors. Additionally, built-in noise immunity structure — included as standard on high-performance digital metal detectors — can dramatically reduce the effects of external electrical noise, again resulting in fewer false product rejects.

Fortress Technology | www.fortresstechnology.com

Fortress Technology Ltd. is a privately-owned Toronto-based company. The company custom manufactures metal detectors to suit customer needs, applications, and specifications while ensuring optimal performance. Dedicated to a Never Obsolete Commitment, new technology is developed to be backwards compatible and accessible. Fortress is a global enterprise providing worldwide coverage from its manufacturing facilities in Canada, the UK, and Brazil.

Leave a Reply

You must be logged in to post a comment.