Couplings are simple devices that connect two shafts together — usually to fix motor output shafts to other rotating equipment to transmit motion. Dictating the most suitable coupling are (among other things) required precision of velocity transmission and overall torque.

Couplings are simple devices that connect two shafts together — usually to fix motor output shafts to other rotating equipment to transmit motion. Dictating the most suitable coupling are (among other things) required precision of velocity transmission and overall torque.

Below are some recent updates on couplings from motioncontroltips.com Design World sister site couplingtips.com. Managed by our colleague Mike Santora, these pages are among the most trafficked pages over the last year. Click on the headlines to read more.

The 5 best Oldham couplings videos on the web

These are five videos (including the one below) that explain the proper installation and operation of Oldham couplings.

Flexible Couplings — Common Mistakes in Assembly and Maintenance

In this post, Stan Riddle of VibrAlign explains how he sees facilities for manufacturing, mining, and municipality applications that use couplings — and see them fail prematurely. Riddle then outlines how to extend flexible-coupling life by avoiding common errors in installation and maintenance.

Changing gears: elastomeric couplings shift focus to simplicity

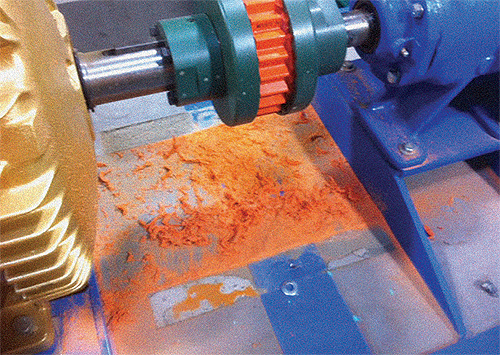

Here, Matt Bamford, Tyler Coffey, and Johannah Nelson of Timken explain how gear couplings work. These are a type of flexible coupling suitable for industrial applications thanks to the way they transmit high torque loads and tolerate misalignment.

But despite widespread use, gear couplings are unsuitable in designs that must transmit extreme torque — or where lubricating parts is difficult.

In this piece, Bamford, Coffey, and Nelson give a couple examples of where elastomeric couplings may work better.

Rigid couplings for power transmission applications

Rigid couplings clamp onto and join two shafts, making them operate as one, but unlike many coupling types, do not accommodate for misalignment. This page outlines the offerings from Stafford Mfg. in rigid couplings.

Leave a Reply

You must be logged in to post a comment.