Florence, KY – A new direct metal-mount or “M-M” RFID (Radio Frequency Identification) system provides tough industrial track-and-trace capability to any manufacturing, assembly or closed-loop logistics process using a non-contact, ISO 15693 compliant passive data carrier technology. This new technology allows the RFID “tag” to be mounted directly on any alloy or metal surface without the typical interference or loss in range.

Balluff’s M-M tags and heads are a new technology in the BIS M series developed by Balluff for flexibility. They offer a range of 52mm to 65mm regardless of the alloy content of the metal, including aluminum, which tends to cause the most loss in range for passive RFID. These new tags are contained in a robust, compact housing to allow flexible mounting and sustainability. Designed to operate in temperatures ranging from -25°C to as high as 130°C for up to 1,000 hours of continuous, idle exposure as well as being passive requiring no batteries, means these tags are maintenance-free.

There are two industrial head options to choose from, both designed for maximum read/write performance. One is a self-contained processor and read/write head with a built-in RS-232 serial interface. The other is a read/write head in an identical housing but it can be connected to any of Balluff’s several remote processors. Using a remote processor expands the communication options to include DeviceNet, Profibus, Ethernet/IP and TCP/IP, Modbus-IP or even the new ProfiNet Ethernet bus.

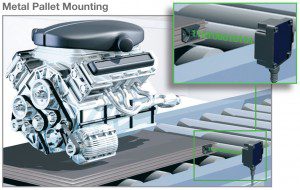

The new M-M ID system greatly improves the flexibility of mounting RFID in industrial applications. These tags can now be mounted directly on metal pallets, totes or even directly on parts without the use of plastic “spacers”, which minimizes complexity and reduces installation costs while providing consistent and reliable read/write performance.

For further information, visit: www.balluff.com/M-M.

Leave a Reply

You must be logged in to post a comment.