One little hydrogen fuel-cell vehicle holds the Guinness world record for the most efficient vehicle … and uses a slotless brushless 60L-H-175-A from Koford Motors to drive its rear power wheel. This year, the tiny car from the Duke Electric Vehicles team beat the 12,600-mpg efficiency of the PAC CAR 2, in turn designed by a student team at the Eidgenössische Technische Hochschule (ETH) in Zürich, Switzerland.

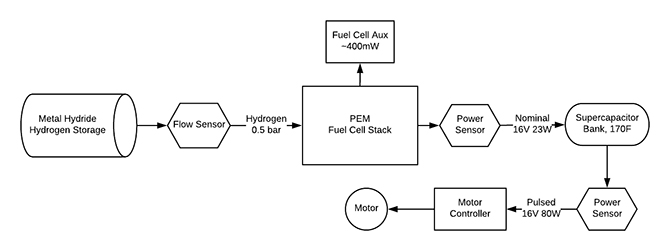

According to Patrick Grady (president of the Duke Electric Vehicles team until he graduated this year) their fuel-cell vehicle Maxwell (in its final World Record iteration) has a 15-mph design speed and 40.8 W of total power (sourced from hydrogen chemical energy). During redesign based of a Maxwell predecessor, the team saw that with a nominal fuel-cell efficiency of 58% average electrical energy from the fuel cell (used by the motor) couldn’t exceed 23.6 W. With a motor and drivetrain efficiency of 87% or so, mechanical power dissipation couldn’t exceed 20.6 W.

The Duke team used the 23-W target extensively to make quick decisions on what components to swap for better.

“For Maxwell prototypes, our Teensy 3.2 microcontroller of choice drew about 300 mW when powered from 5 V … so had we used the Teensy in the final Maxwell design, we would’ve lost 1.3% efficiency just powering the microcontroller,” explained Grady.

Another key to ensuring efficiency was calculating the average power level and then optimizing the fuel-cell system for top efficiency there. But average motor load over a representative race is 23 W … and the Duke team’s original design used a motor most efficient at 80 W.

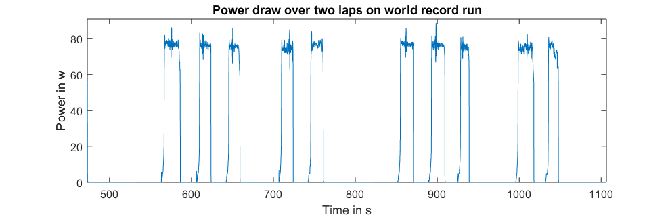

Yet another wrinkle: To maintain speed during races, the driver cycles the motor on and off. So to allow this mode of operation, the team considered a few system architectures:

No load levelling — with the motor controller directly connected to fuel-cell output with no energy storage between the two

Passive load levelling — with a large supercapacitor bank connected to the fuel-cell output

Active load levelling — with a custom DC/DC converter between fuel cell and supercapacitor bank for total fuel-cell control

The first approach would’ve required the fuel cell to supply full motor power … and optimization around 80-W motor power instead of the car’s nominal 23 W. Making matters worse, such a design would’ve necessitated “optimization” for 0-W conditions — requiring low gas leakage and latent current draw in such situations. So the team vetoed this design.

The second method was one the Duke team used on their Gemini car — for a 2018 Shell Eco-Marathon race. This setup employs a dc/dc converter to actively control power with software to stepup fuel-cell voltage to higher supercapacitor and motor voltage. The configurable converter drew constant power from the fuel cell and into a supercapacitor bank for efficiency. This entirely decoupled the fuel cell from the motor and was the theoretically cleanest option. But in the 2018 Eco-Marathon, the Duke team only got 96% efficiency from the converter. Plus it (and associated software and hardware) introduced complexity and design issues.

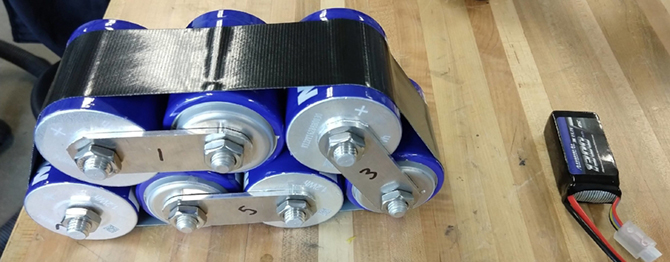

So for Maxwell’s world-record run, the Duke team employed passive load levelling. Here, a supercapacitor bank connects in parallel to the fuel cell and motor controller. The fuel cell continuously trickles power into the supercapacitors … and then motor discharges the bank in high-power bursts. Supercapacitor size was chosen to hold voltage and power draw off the fuel cell constant over a lap. The supercapacitors added about 2 kg to the vehicle weight, but their simplicity made the car design more robust — and losses from the dynamics of the fuel cell were smaller than the losses from dc/dc converter to boot.

More specifically, supercapacitors run at better than 99% efficiency (with losses from internal resistance) … and that of Maxwell vehicle’s supercapacitor bank is only about 10 mOhm — far lower than that of comparable lithium-ion solutions.

Electric motors do their part maintaining the car’s efficiency

Critical to Maxwell’s efficiency is having an efficient electric motor that’s also light and reconfigurable to myriad input voltages.

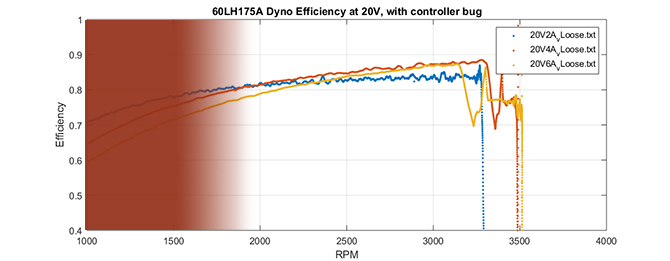

“Few motor manufacturers list their motors’ theoretical efficiency, and still fewer have measured dyno results. Unfortunately, most vendors focus on optimizing power density or cost … so we struggled to find resources focused on efficiency,” said Grady. “Our team ultimately chose Koford Motors to power Maxwell. Their data sheets very helpful and their motors highly efficient — with dyno results to quantify that efficiency.”

More specifically, the team picked a Koford 60L-H-175-A motor — with a peak efficiency of about 92% and well-suited sizewise for Maxwell.

Paired to the brushless motor is a chain transmission — to transfer power from the motor shaft to Maxwell’s rear wheel. On the final record-setting Maxwell powertrain, a #25 chain runs on a 14T sprocket coupled to the Koford motor …and then a 120T sprocket drives a freewheel on Maxwell’s rear wheel. The chain transmission let the Duke team easily change gear ratios to let the motor run at peak efficiency … which was helpful, as the motor and drive are most efficient at 100% duty cycle (near top speed).

Direct-drive option? Not for this efficient design

The Duke team considered using a direct-drive hub motor in Maxwell, as such motors are theoretically more efficient than electric motors connected to power-transmission components. But the team only found hub motors that were heavy, poorly documented, or designed for low-cost electric bikes.

Maxwell’s motor controller uses Hall-sensor feedback for simple block commutation. The team tried out a blended Hall and back-EMF commutation for more accurate timing but found its implementation didn’t match the performance of classic Hall commutation.

To save power, Maxwell was programmed to shut off most electrical systems when the motor wasn’t running. The car’s driver was given just a button control the motor — not the more standard throttle potentiometer. Upon depression, the button triggers a wake-up sequence and throttles the motor at constant current. Removing the driver’s throttle control boosts consistency and performance by keeping the electric motor running near its optimal point.

Visit this blog deep link on duke-ev.org for more information from Patrick Grady about the Maxwell fuel-cell vehicle — and on challenges related to getting top performance out of Maxwell’s off-the-shelf Horizon H-100 PEM fuel cell. At the blog, Grady also explains the advanced analysis the team performed on various racetracks to pick one that would give Maxwell the best odds of beating the world record for vehicle efficiency.

Leave a Reply

You must be logged in to post a comment.