Here we outline leading factors affecting the longevity and performance of industrial robot joints. Links refer to supporting research listed at the feature conclusion.

Recent years have seen continuous demand in numerous industries — automotive manufacturing to computer, communication, and consumer electronics (3C) product fabrication — for industrial robots. Compared to automated dedicated equipment in traditional production lines, robots have superior operational flexibility and capabilities. So, they’re especially suitable for multi-species and small-batch production — for rapid response to market changes and consumer needs.

Back to basics: What makes an industrial robot

To review, industrial robots are automatically controlled programmable multipurpose manipulators that move loads in three or more axes. Advantages of using industrial robots include improvements in quality and productivity; reduction in manufacturing variability; savings in raw materials; reduced product lead time; and reduction in long-term total manufacturing costs. In addition, they have been widely used to free human workers from repetitive tasks and dirty or dangerous environments.

Increased use of industrial robots has spurred demand for leveraging the technology’s full potential. Case in point: Industrial robots are increasingly used in the motion control industry for optimizing manufacturing throughput. That has in turn driven industrial and scientific efforts to design next-generation industrial robots.

Significant advances in actuator and control technology have enabled the evolution of sophisticated modular robot joints. Modular robot joints are standardized yet capable of interfacing with a myriad other parts and systems. Modularity allows for versatility in design and machine capabilities; adaptability; and ease of assembly. Integrated mechatronic modular joints outperform conventional robotics as well — with higher power density, dynamic performance, and reliability along with lower weight.

One caveat is that industrial robots can incur significant upfront investment. Decisive factors when considering the robots to replace expensive human labor are the payback period in capital investment and robot service life. Quick payback and long service life maximize return.

Certain motion-component manufacturers are well versed in servo-motion components used in the robotic industry. OEM collaborative robot (cobot) designs with light payloads are optimizable by the inclusion of one or more modular robot joints; some such modular robot joints integrate frameless torque motors in the form of alternating current permanent magnet (PMAC) servo motors for simple and safe designs. Careful engineering means some frameless motors are optimized to adhere to space or weight constraints or performance and reliability requirements.

Now let’s outline various factors affecting the longevity and performance of industrial robot joints.

Thermal effects reduce life of components in robots

High temperatures degrade industrial-robot life. Consider a mechatronic robot joint module: This contains a frameless motor, servo drive, dedicated gearing system, brake, encoder or resolver, torque sensor, connection cables, and so on in a single compact housing. Normal operation causes heat generation inside this housing — mostly originating from the gearing, motor windings, and brake coil if applicable — along with other electric and electronic components. Gearing is the most significant heat source if strain-wave gearing is used — contributing up to 30% of the total power loss due to gear-mesh friction, viscous lubricant shear friction, and energy invested in repeatedly distorting the metallic flexspline every revolution. Ineffective heat dissipation will cause the robot to get hot and exhibit diminished performance.

Common in robot joints: Strain-wave gearing

A robot joint’s output shaft typically rotates at 10 to 40 rpm. A motor typically rotates at 1,000 to 4,000 rpm for short bursts during robot joint movements. So, gearing reduces speed and increases acceleration torque at the output … for high torque density relative to its dimensional footprint (torque per unit volume) and specific torque (torque per unit mass).

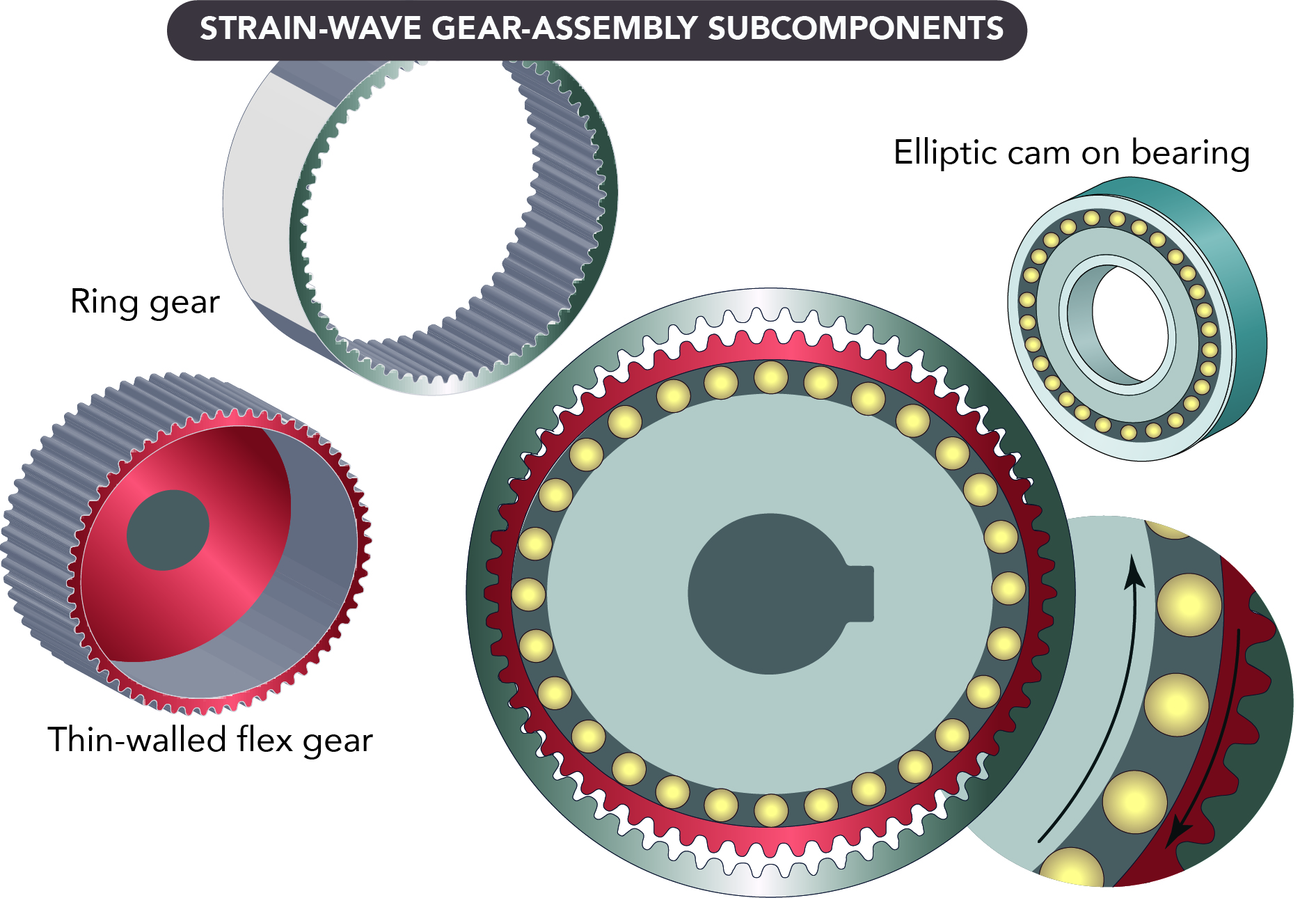

Strain-wave gearing mechanisms offer distinct advantages that justify their use in industrial applications and robots … such as a high gear ratio in a single stage; at or near-zero backlash and simple structure; precise torque transmission; and high positioning accuracy and repeatability. Strain-wave gearing includes an ellipse-shaped wave generator, a flexspline, and a circular spline. The flexspline is the life-limiting subcomponent. During operation, it sees constantly changing amounts of elastic deformation from the rotation of the ellipse-shaped wave generator — and must rotate with minimal angular deflection. So, the flexspline must be flexible in the radial direction but stiff in the tangential direction to accurately transmit rotational motion.

Power losses in the strain-wave gearing are due to various mechanisms including:

Friction loss due to gear meshing between flexspline teeth and rigid circular spline in the three teeth meshing stages — engagement in, engagement, and engagement out. Unlike conventional gearing, teeth movement in a stain-wave mechanism is primarily sliding due to a small phase shift between the corresponding teeth in engagement. Sliding between the teeth causes energy losses and heats the assembly to an equilibrium of 60 to 70° C.

Molecular friction loss due to viscous friction in the lubricant.

Bearing friction loss in the cross-roller bearing, wave generator bearing, and other bearings.

Mechanical loss due to periodically repeated elastic strain energy, due to torsional and radial deformations of the flexspline.

Some of these power losses are strongly influenced by operation temperature.

Conventional gearing systems usually exhibit some level of backlash. Backlash lowers the accuracy of gearing system but provides space for lubrication and thermal expansion. Given that a strain wave gearing inherently has nearly zero backlash, at high temperature the thermal expansion on its gear elements may spur an interference between meshing gears — and increase the tooth contact pressure and meshing friction.

Wear characteristics of strain-wave gearing depend heavily on the condition of the lubricant, in turn affected by operating temperature. Excessively high temperatures may spur the breakdown of the lubricant film which in turn allows scuffing damage on the gear-teeth contact surfaces.

The efficiency of strain-wave gearing is proportional to the load percentile (load torque to allowable average torque) and allowable operation temperature — and is inversely proportional to the input speed (gear ratio). Maximum temperature ratings are 50 to 70° C depending on the manufacturer and lubricant rating.

Electrically actuated brakes are another heat source

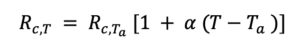

Electrically actuated brakes are common on industrial robots. Brakes in these applications typically include an electromagnetic inductive coil with a mechanical spring mechanism to engage a holding friction (interference) state upon voltage removal from the coil. Brake coils energized during motor movement generate heat. Then coil electrical resistance increases with coil resistance Rc at temperature T varying linearly with the temperature differential between the operation temperature T and the ambient temperature Ta defined as:

Where α = Material temperature coefficient (for copper magnetic wire α = 0.00393 per ° C) and Ta = Ambient temperature and with:

![]() = Electrical resistance of the coil at the ambient temperature … so if temperature rises 30° C above ambient temperature, coil resistance increases 12%.

= Electrical resistance of the coil at the ambient temperature … so if temperature rises 30° C above ambient temperature, coil resistance increases 12%.

Frameless-motor temperature considerations

Frameless motors fit applications where size and weight are top design objectives. Compared to housed motors, this motor type may offer end users commercial and technical competitive advantages — including high torque density, enhanced heat dissipation capabilities, and flexibility for customized designs. Integrating frameless (stator and rotor) motors directly onto the bearings already supporting the gearing components minimizes overall robot-joint size and eliminates redundant components. The latter might include extra bearings to support the rotor, separate shaft and coupling to between the motor shaft and gearset’s wave generator.

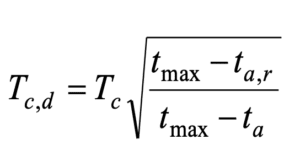

Rated continuous-torque values listed in motor manufacturer catalogs are based on set ambient temperatures — usually 40° C. When actual ambient temperature exceeds rated values, motor performance deteriorates and at low speeds near stall the its output torque reduces:

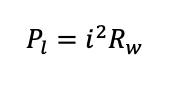

Where tmax = Maximum motor winding temperature, ta = Rated ambient temperature, ta,r = Real ambient temperature, Tc = Rated continuous (low speed) torque, and Tc,d = Derated torque at real ambient temperature. So, with tmax = 80° C, ta = 40° C, and ta,r = 60° C, derated torque is 70.7% of the original continuous torque. At low speeds the frameless-motor power losses are dominated by the cooper losses in the motor windings. Power loss due to winding resistance Pl is related to current i and electrical winding resistance Rw:

As demonstrated by the Rc,T equation discussed earlier related to brake coils, higher temperature directly causes a higher winding resistance Rw … and that in turn makes for higher power loss in the robot joint arm.

The torque de-rating formula doesn’t account for non-I2R motor losses such as iron losses … so as these iron losses increase as a function of speed, the torque derating will be more pronounced than this calculation predicts.

The iron losses in the motor’s core are a function of both the fundamental electrical frequency and flux density levels of the motor’s magnetic circuit. The pole count of the motor determines the fundamental frequency and the design of the stator core and permanent magnets set the flux density levels. In particular, the eddy current iron loss is a function of both the fundamental frequency squared and flux density squared.

The operating speeds of the robot’s application are a key factor in the electromagnetic design of the frameless-motor as the selection of the motor pole count and design of the stator core determine the balance of I2R and iron losses. An optimized electromagnetic design results in the best motor efficiency across the robots operating speed range.

Robots’ sensor sensitivity to heat

Robots use many sensors — including encoders, resolvers, and torque sensors. A key characteristic of these sensors is their sensitivity to temperature. For optical encoders, the increase in temperature causes a decrease in the LED’s light output. Thermal expansion also impacts optical encoder performance. In fact, thermal expansion can narrow the air gap between the disk and the source (detector) by 0.020 in. (0.51 mm) in some situations. Extreme instances of such thermal expansion can bring the subcomponents into contact and cause encoder damage or even catastrophic failure. For magnetic encoders, thermal expansion and contraction of the magnetic wheel can alter the pitch of the magnetic poles and thus alter the output.

Servo drive and other electronic components

Servo drives are key in a variety of robots including cobots, industrial articulated robots, and medical robots. But electronic component failure rates skyrocket at high temperatures. The Arrhenius law states that for every 10° C increase in operating temperature above the rated temperature, life expectancy will be halved.

As one of the major sources of electric noise, thermal noise arises from the thermal fluctuations in the electron density within a conductor and thus is always present in electronic circuits. It highly depends upon the temperature — in other words, the higher the temperature, the higher the thermal noise level. The only way to reduce the thermal noise content is to reduce the temperature of operation.

Bearing lubrication in robotic joints

Lubrication has significant influence on the performance of both motors and strain-wave gearing. Several bearings types are used in robots — cross-roller bearings, wave generator bearings, and regular deep-groove ball bearings. These bearings are lubricated by mineral oil-base greases.

Of course, bearing friction is affected by several factors — including temperature, velocity, load, lubricant properties, and operating conditions. Temperature changes causes significant grease-viscosity and molecular-friction changes. Cold can significantly reduce the oil-release characteristics of grease and lead to insufficient lubrication — with the potential for wear and system failure. As a comparison, high temperatures can sheer or crack the oil molecules into smaller molecules for decreased viscosity. This may induce oil leakage from the bearing. In fact, high temperatures can also trigger two other grease failure mechanisms:

Oil oxidation can lead to increased oil viscosity, deposits, and the loss of the ability to form a protective lubricant film. The second failure mechanism unique to grease is a waning ability of the thickener to retain the oil phase. Under extreme conditions, the latter can induce permanent loss of lubricating oil.

As a rule of thumb, the rate of chemical reactions (which includes oxidative and thermal degradation) changes by a factor of two for every 10° C change in temperature. That means increasing temperature by 10° C doubles the rate of reaction — halving expected life. Elevated temperatures drive grease failure modes quickly as they increase.

Robot motion components in harsh environments

Some types of industrial robots are designed to operate in harsh environments such as spray painting robots, welding robots, and polishing and grinding robots. Such extreme conditions like wet or muddy terrain, dust, humidity, vibration and shock, corrosion, toxic conditions (such as radiation) and so on can significantly influence the robot’s performance and life.

Industrial robots with different exterior coatings, materials, and seals differ in their ability to withstand harsh conditions. Most robots arrive at the end user already sealed. But after an extended period of service, thermal cycling may cause pressure changes and seal failures — for ingress paths and places that allow external debris to get inside the robot.

Optical encoders detect rotary motion with optoelectronic components (including fine-pitch scales, LEDs, and photodetectors) that can be seriously harmed by contamination. Exposure to dust, dirt, water, or oil can cause partial or complete encoder failure over time. Optical encoders subject to significant vibration or shock can also fail if the optical disk cracks or shatters — especially those using a glass disk.

Bearings are also sensitive to contamination. Dirt, dust, and other foreign objects that enter a bearing can cause scratches, pits, and lapping on the raceway surface — as well as premature damage. Moisture can degrade a bearing in several ways. Bearings exposed to moisture may corrode or become etched on its exposed surfaces for localized spots of corrosion. This pattern of corrosion in turn makes for excessive noise, unplanned clearances, and corrosion fatigue in corroded zones.

All other robot parts, from electric motors to electronic components, can corrode when exposed to harsh environments. The miniaturizing design of the servo drive integrated into a robot joint has greatly reduced the space between electronic components, making them easier to integrate into a robot. But such designs also heighten the risk of exposure in corrosive settings. In practice, corrosion may occur throughout the robot’s entire life cycle during various stages of manufacturing, assembly, transport and storage of robots, as well as field operations.

Loading and vibration during operation

Robot payload and overall system inertia affect robot dynamic characteristics and position control accuracy. Robot payload refers to the weight a robot can lift and move beyond just its own structural mass. When a robot carries very high load, fractures may occur on the teeth of the gearing. In fact, tooth breakage is often caused by mechanical overloads that exceed the gear materials’ tensile strength.

Overall system inertia is the sum of the load inertia and robot inertia. It plays a key role in rotational kinetics and represents the tendency of the loaded object and robot to resist changes in motion — namely to speed and direction. Higher system inertia generally makes for lower positioning control accuracy. That said, today’s latest high-bandwidth drive technology with high-resolution feedback devices has minimized many of these effects and limitations.

A robot arm in operation is subject to a variety of external loads and inertia forces depending on its position, orientation, and moving velocity. When the robot executes certain tasks — such as carrying payloads exceeding its published rating, performing fast maneuvers, and interacting large forces or moments within the unstructured environment — the robot may lose its dynamic balance and motion stability. Where a robot experiences an acceptable payload but a very high inertia, it may cause the robot to accelerate slowly, not work properly, or even render the robot incapable of making the commanded move. So safe robot operation depends on careful consideration of both the payload (inertia) and effective contact force control.

A strain-wave gear may have several types of failure modes. Fatigue fracture of the flexspline is the most common failure mode. Testing on strain-wave gearing indicate that as early as four million input revolutions (for a motor running at 3,000 rpm this is equivalent to 22.2 service hours) the tooth profile was completely obliterated and damaged across the entire width of the flexspline teeth — and most of the width of the circular spline — from improper operation. What’s more, strain-wave gearing exhibits high-frequency oscillation (torque ripple) in its output torque. This mainly arises from gear-meshing vibration.

Every robot system has its own resonant frequency at which vibration occurs. For rotation-excited vibration, the resonance is known as the critical speed. End users must avoid operating robots near their inherent resonant frequencies.

Industrial robots often operate in complex environments while interacting closely with human workers and performing a wide variety of tasks. In fact, dynamic stability is one of the most crucial factors affecting robot performance and workplace safety, especially for robots with large payloads, wide movement ranges, and high moving speeds. ⚙️ This feature was contributed by Kollmorgen engineering staff.

References supporting this article:

[1] Schafer, I. et. al. (2005). Space lubrication and performance of harmonic drive. Proceedings of the 11th ESMATS Symposium, pp. 65-72, Lucerne, Switzerland

[2] Kircanski, N. M. and Goldenberg, A. A. 1997. An experimental study of nonlinear stiffness, hysteresis, and friction effects in robot joints with harmonic drive and torque sensors. Intl. Journal of Robotics Research 16(2): 214-230.

[3] Dynapar: How temperature and humidity affect encoder performance.

[4] Bilgin, B., Sathyan, A. (2014). Fundamentals of electric machines, in Advanced Electric Drive Vehicles (edited by Ali Emadi). CRC Press: Boca Raton, FL.

[5] Exxon Mobil Corporation. 2012: Lubricating grease basics.

[6] Lojans, A. and Kakitis, A. 2012. Evaluation of environmental factors influencing robots in greenhouses. Proceedings of 11th Intl. Scientific Conference – Engineering for Rural Development, pp. 151-156. Jelgava, Latvia..

[7] Schafer, I, Bourlier P, Hantschack, F, Roberts, E. W., Lewis, S. D, Forster, D. J., et al. 2005. Space lubrication and performance of harmonic drive gears. Proceedings of the 11th ESMATS Symposium, pp. 65-72. Lucerne, Switzerland.

[8] Johnson, M. R., Gehling, R., and Head, R. 2006. Failure of harmonic gears during verification of a two-axis gimbal for the Mars reconnaissance orbiter spacecraft. Proceedings of the 38 Aerospace Mechanisms Symposium. Williamsburg, Virginia.

[9] Bhadeshia, H. K. D. H. 2016. Prevention of hydrogen embrittlement in steels. ISIJ Intl. 56(1): 24-36.

Leave a Reply

You must be logged in to post a comment.